HSS Steel Round Bar Alloy Round Tool Steel Bar/M2/M25M42/D2/H13

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 556 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel round bar:

Characteristic:Tungsten-molybdenum high speed steel developed by China,high performance in toughness ,hardness, high temperature hardness.

Festures of steel round bar:

Anneal temperature: 840-860

Relief annealing temperature: 720-760

Hardening temperature: 1210-1230

Hardening medium: salt bath under 600,aslo use oil cooling or air cooling

Normal temper temperation: 540-560 RC Rockwell Hardness after hardening and temperature: 63-66

Production Capacity: 1000 Tons/Month

Tech:EAF+LF+VD+ESR

High strength at elevated temperatures

Specifications of steel round bar:

| C | Si | Mn | W | Mo | Cr | V | P | S |

| 0.80-0.90 | 0.20-0.45 | 0.15-0.40 | 5.50-6.75 | 4.50-5.50 | 3.80-4.40 | 1.75-2.20 | ≤0.030 | ≤0.030 |

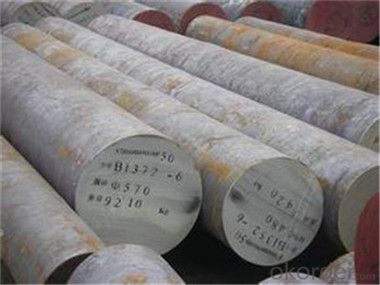

Images of steel round bar:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the typical dimensions of a steel round bar?

- The dimensions of a steel round bar can vary depending on the specific application and industry requirements. Generally, diameter sizes for steel round bars range from 1/4 inch to 24 inches. These sizes are often measured in increments of 1/8 inch or 1/4 inch. The length of a steel round bar is usually standardized at 20 feet, although shorter lengths may also be available. It is important to consider that these dimensions can significantly differ based on the grade and type of steel used, as well as the manufacturing process. Therefore, it is crucial to refer to the appropriate industry standards or consult a supplier for precise dimensions required for a particular project.

- Q: How are steel round bars used in the construction of high-rise buildings?

- Due to their strength, durability, and versatility, steel round bars are commonly utilized in the construction of high-rise buildings. Carbon steel is typically used to manufacture these bars because it possesses excellent mechanical properties and can endure high loads and pressures. In reinforced concrete structures for high-rise buildings, steel round bars are primarily employed. They serve as reinforcement in concrete beams, columns, and slabs. By embedding the bars in the concrete, the overall structure gains added strength and stiffness. One of the main benefits of utilizing steel round bars is their ability to withstand tension forces. Concrete is strong in compression but weak in tension. Therefore, the steel bars act as tension reinforcement, preventing the concrete from cracking or failing when subjected to tension loads. This significantly improves the building's structural integrity and overall safety. Moreover, steel round bars offer easy bending, shaping, and welding, allowing for flexible design and construction options. They can be customized to specific lengths and diameters to meet the requirements of the building project. This adaptability makes them ideal for constructing various structural elements, like beams and columns, which must be precisely engineered to support the weight and stresses of a high-rise building. Furthermore, steel round bars exhibit excellent resistance to corrosion, which proves crucial when constructing high-rise buildings exposed to various environmental elements. The steel's corrosion-resistant properties ensure the structure's long-term durability and lifespan. In conclusion, steel round bars are essential in the construction of high-rise buildings as they provide strength, durability, and flexibility to reinforced concrete structures. They enhance the overall structural integrity, safety, and longevity of the building, making them a crucial component in modern construction practices.

- Q: What is the maximum copper content allowed for steel round bars?

- The permissible copper content in steel round bars varies depending on the grade and industry standards. Generally, copper is regarded as an alloying element in steel and is usually added in small quantities to improve specific properties. For most steel round bars, the maximum acceptable copper content typically ranges from 0.50% to 1.00%. However, it is crucial to consider that this may differ based on the application and grade of steel utilized. To determine the maximum allowable copper content, it is advisable to refer to the applicable industry standards or specifications for the specific steel grade and application.

- Q: Can steel round bars be used for making bearings?

- Making bearings can indeed involve the use of steel round bars. However, it is crucial to acknowledge that the suitability of steel round bars for bearing applications relies heavily on the specific type of steel utilized and the manufacturing process employed. Bearings commonly encounter high loads and necessitate qualities such as good wear resistance, low friction, and high durability. For this reason, steel round bars made from top-notch alloy steels, such as chrome steel or stainless steel, are frequently employed in bearing production due to their exceptional mechanical properties. These steel round bars undergo particular heat treatment procedures, such as quenching and tempering, to enhance their hardness, strength, and wear resistance. Moreover, the round bars are usually machined with precise tolerances to ensure proper fit and alignment within the bearing assembly. To guarantee the most optimal performance, reliability, and longevity of bearings under various operating conditions, it is essential to seek advice from materials and manufacturing experts or consult industry standards. This will ensure the appropriate selection of steel round bar material and manufacturing processes for bearing applications.

- Q: What are the different methods used for machining steel round bars?

- There are several methods used for machining steel round bars, each with its own advantages and applications. Some of the commonly used methods include: 1. Turning: This is a widely used method that involves rotating the steel round bar against a cutting tool, which removes material and creates the desired shape. Turning is suitable for both external and internal operations and can achieve high precision and surface finish. 2. Milling: In milling, a rotating multi-tooth cutter removes material from the steel round bar to create flat or contoured surfaces. This method is versatile and can be used for various operations, including face milling, slotting, and profiling. 3. Drilling: Drilling involves creating holes in the steel round bar using a rotating drill bit. This method is commonly used for creating holes of different sizes and depths, and can be done manually or through automated processes. 4. Grinding: Grinding is a precision machining method that uses abrasives to remove material from the steel round bar. It is commonly used to achieve a smooth surface finish, tight tolerances, and precise dimensions. Grinding can be performed using various types of grinding machines, such as cylindrical grinders or surface grinders. 5. Boring: Boring is used to enlarge existing holes or create internal cylindrical shapes in the steel round bar. It involves rotating a cutting tool inside the bar to remove material and achieve the desired dimensions and surface finish. 6. Broaching: Broaching is a specialized machining method used to create complex internal or external shapes in the steel round bar. It involves using a broach, a multi-toothed cutting tool, that is pushed or pulled through the bar to remove material and create the desired shape. 7. Sawing: Sawing is a method used to cut the steel round bar into desired lengths or shapes using a rotating blade with teeth. This method is efficient for mass production and can be performed using manual or automated sawing machines. These are just a few of the methods used for machining steel round bars. The choice of method depends on factors such as the desired shape, dimensions, tolerances, and surface finish, as well as the production volume and available equipment.

- Q: What are the advantages of using nickel-tin alloy steel round bars?

- There are several advantages of using nickel-tin alloy steel round bars. Firstly, the addition of nickel improves the corrosion resistance of the steel, making it suitable for applications in harsh and corrosive environments. Secondly, tin improves the machinability and workability of the steel, allowing for easy shaping and fabrication. Additionally, the alloy steel round bars exhibit high strength and excellent mechanical properties, making them ideal for structural applications that require durability and reliability. Lastly, the combination of nickel and tin enhances the overall performance and longevity of the steel, making it a cost-effective choice in various industries such as automotive, aerospace, and marine.

- Q: Can steel round bars be used for making wire?

- Steel round bars are capable of being utilized for the production of wire. A technique known as wire drawing is employed to convert steel round bars into wire. This method involves pulling the steel round bar through a succession of progressively smaller dies in order to decrease its diameter until it achieves the desired wire size. This technique is widely employed in the manufacturing of different wire types, such as steel wire used in construction, electrical wiring, fencing, and other diverse applications. Typically, the steel round bars employed for wire production are crafted from carbon steel, which imparts the requisite strength and longevity for the wire to fulfill its various purposes.

- Q: How are steel round bars used in the manufacturing of hydraulic systems?

- Steel round bars are commonly used in the manufacturing of hydraulic systems as they provide strength, durability, and stability to various components such as pistons, cylinders, and shafts. They are machined and shaped to create precision parts that can withstand high pressure and repetitive movements. The use of steel round bars ensures the reliable and efficient functioning of hydraulic systems, making them an integral part of their construction.

- Q: What are the different surface treatments available for alloy steel round bars?

- Some of the different surface treatments available for alloy steel round bars include black oxide coating, galvanization, chrome plating, nitriding, and powder coating. Each treatment offers unique benefits such as enhanced corrosion resistance, improved wear resistance, increased hardness, and aesthetic appeal. The choice of surface treatment depends on the specific requirements and desired performance characteristics of the alloy steel round bars.

- Q: Are steel round bars recyclable?

- Yes, steel round bars are recyclable. Steel is one of the most commonly recycled materials in the world, and round bars made of steel can be easily melted down and reused to make new steel products.

Send your message to us

HSS Steel Round Bar Alloy Round Tool Steel Bar/M2/M25M42/D2/H13

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 556 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords