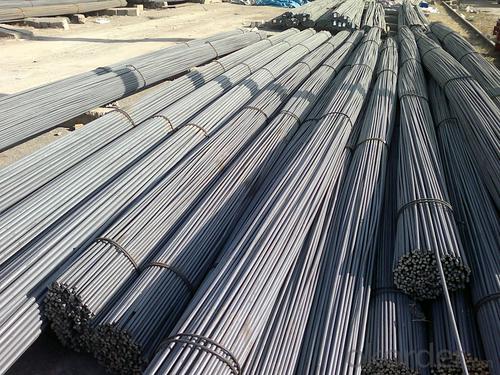

Hot Rolled Steel Round Bar 6mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Chinese Standard Round Bar

1. Grade: Q195, Q235, Q345

2. Diameter: 6mm-150mm

3. Length: 6m, 9m, 12m or as customer’s request

4. Tolerance: Within ±5% for weight; ±2mm for diameter

5. Note: The price can be better is the quantity is good

6. Chemical composition

Alloy No | Element (%) | ||||

C | Mn | S | P | Si | |

Q195 | 0.06-0.12 | 0.25 | ≤0.05 | ≤0.045 | ≤0.3 |

Q235 | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Q345 | ≤0.2 | 1.00-1.60 | ≤0.045 | ≤0.045 | ≤0.55 |

Usage and Applications of Chinese Standard Round Bar

1. Chinese standard steel bar is often used where large amounts of steel need to be formed, for example as structural steel.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Steel round bar is used in construction and a large number of architectural and engineering structures.

Packaging & Delivery of Chinese Standard Round Bar

Packaging Detail: All goods are packed in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: 45 days

Trade terms: FOB, CFR, CIF

MOQ: 25 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request and the situation of the port of destination.

Documents given: Full set of original clean on board bill of lading; Original signed commercial invoice; Original packing list; Policy of insurance; Certificate of origin and what the target market needs.

Production Flow of Chinese Standard Round Bar

1. The common processes are preheated forging quenching, dual refinement solution process, cooling quenching and isothermal quenching. We use heat treatment for dual refinement solution process.

2. Material prepare (billet) — heat up — rough rolling — precision rolling — cooling — packing — storage and transportation

Characteristics of Chinese Standard Round Bar

1. The steel in which the main interstitial alloying constituent is carbon in the range of 0.12–2.0%.

2. As the carbon percentage content rises, steel has the ability to become harder and stronger through heat treating; however it becomes less ductile.

3. Quality should be in conformity with the specification of the manufacturer. Quantity and packing conditions should be in conformity with the term in the contract.

4. Regardless of the heat treatment, higher carbon content reduces weld ability. In carbon steels, the higher carbon content lowers the melting point.

- Q: Can steel round bars be used for making stabilizer bars?

- Stabilizer bars can indeed be made using steel round bars. The automotive industry commonly employs steel due to its exceptional durability, high strength, and resistance to deformation. Stabilizer bars, also referred to as sway bars, are crucial components in a vehicle's suspension system. Their purpose is to enhance stability while cornering and minimize body roll. These bars endure substantial forces and must possess the ability to withstand heavy loads. Steel round bars offer the essential strength and rigidity necessary for stabilizer bars to effectively fulfill their function. Moreover, steel is easily accessible and cost-effective, which contributes to its popularity as a preferred material for manufacturing stabilizer bars in the automotive industry.

- Q: How are steel round bars used in the manufacturing of heat exchangers?

- Steel round bars are commonly used in the manufacturing of heat exchangers as they provide structural support and durability to the equipment. These bars are often used as the framework or as internal support for the heat exchanger's core, ensuring stability and longevity. Additionally, steel round bars can be machined or formed into various shapes to accommodate specific design requirements, allowing for efficient heat transfer and optimal performance of the heat exchanger.

- Q: Can steel round bars be used in the production of HVAC equipment?

- Yes, steel round bars can definitely be used in the production of HVAC (Heating, Ventilation, and Air Conditioning) equipment. Steel round bars are widely utilized in the manufacturing of various HVAC components such as air ducts, frames, supports, brackets, and other structural elements. Steel is a popular choice in HVAC equipment due to its excellent strength, durability, and resistance to corrosion. Its high tensile strength makes it suitable for handling the mechanical stresses and loads experienced by HVAC systems. Additionally, steel can withstand high temperatures and is non-combustible, making it a safe material for HVAC applications. Overall, steel round bars are widely utilized in the production of HVAC equipment for their reliability, longevity, and performance.

- Q: What is the difference between a cold finished and a hot rolled steel round bar?

- A cold finished steel round bar and a hot rolled steel round bar differ in their manufacturing processes and resulting properties. Cold finished steel round bars are manufactured through a cold drawing process, where the steel is pulled through a die at room temperature. This process results in a smooth, polished surface with tight dimensional tolerances. The cold drawing process also enhances the strength, hardness, and overall mechanical properties of the steel. Cold finished steel round bars are often preferred for applications where precision and a smooth surface are crucial, such as in machinery, automotive parts, and tools. On the other hand, hot rolled steel round bars are manufactured by heating the steel to a high temperature and then rolling it through a series of rollers. This process allows for the shaping and forming of the steel while it is in a pliable state. Hot rolled steel round bars have a rough, scaled surface and looser dimensional tolerances compared to cold finished bars. They also tend to have a slightly lower strength and hardness than their cold finished counterparts. Due to their more affordable cost and ease of production, hot rolled steel round bars are commonly used in construction, structural components, and general fabrication. In summary, the main differences between cold finished and hot rolled steel round bars lie in their manufacturing processes and resulting properties. Cold finished bars offer enhanced strength, precision, and a smooth surface, making them suitable for applications requiring high precision and mechanical performance. Hot rolled bars, on the other hand, have a rougher surface and looser tolerances, but their affordability and ease of production make them a popular choice for general applications.

- Q: What is the difference between hot-rolled and cold-rolled steel round bars?

- Hot-rolled and cold-rolled steel round bars differ primarily in the manufacturing process, resulting in distinct physical and mechanical properties. Hot-rolled steel round bars are formed by heating a billet or ingot at extremely high temperatures, typically above 1700°F (926°C). This intense heat allows the steel to be malleable and capable of being shaped into the desired form. The hot rolling process involves passing the heated steel through large rollers, which progressively reduce the diameter and increase the length. As a result, hot-rolled bars have a rough and scaled surface with rounded edges. The quick cooling after rolling also forms an oxide layer or mill scale on the surface. On the other hand, cold-rolled steel round bars are produced by a process that involves rolling the steel at room temperature or slightly below. This process provides greater control over the dimensions and surface finish of the bars. Cold rolling involves passing the steel through smaller rollers, which exert high pressure to shape and compress the material into the desired form. The cold-rolling process results in a smoother and more precise surface finish, with sharper edges compared to hot-rolled bars. Additionally, since the steel is not heated to high temperatures, it retains its strength and hardness properties. The distinct manufacturing processes lead to differences in the mechanical properties of hot-rolled and cold-rolled steel round bars. Hot-rolled bars tend to have a higher yield strength and are generally more ductile, making them suitable for applications requiring extensive shaping or bending. Cold-rolled bars, on the other hand, have a higher tensile strength and are generally harder, making them suitable for applications requiring higher strength and dimensional accuracy. In summary, the key differences between hot-rolled and cold-rolled steel round bars lie in the manufacturing process, resulting in variations in surface finish, dimensional accuracy, and mechanical properties. The choice between the two depends on the specific requirements of the intended application.

- Q: What are the tolerance levels for steel round bars?

- Steel round bars have varying tolerance levels depending on the specific application and industry standards. To ensure precision in terms of diameter, straightness, and surface finish, steel round bars are typically produced with tight dimensional tolerances. Diameter tolerances specify the acceptable range of deviation from the nominal diameter of the round bar and are expressed as a plus or minus value, such as +/- 0.005 inches. The specific tolerance depends on the size, type of steel round bar, and application requirements. Straightness tolerances determine the allowable amount of deviation from a perfectly straight line along the length of the round bar. This tolerance is expressed as the maximum distance between the round bar and a straight edge placed along its length. For instance, a straightness tolerance of 0.030 inches per foot means that a one-foot section of the round bar can deviate up to 0.030 inches from a straight line. Surface finish tolerances specify the acceptable level of imperfections or irregularities on the surface of the round bar. This tolerance is often expressed using roughness average (Ra) or roughness peak (Rz) values. The specific tolerance depends on the desired surface finish and application requirements. It is worth noting that tolerance levels may also be subject to industry-specific standards established by organizations like the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). These standards provide guidelines and specifications for various steel products, including round bars, to ensure consistent quality and performance. Ultimately, determining the tolerance levels for steel round bars involves considering the specific application requirements, industry standards, and the capabilities of the manufacturing process.

- Q: Can steel round bars be used for making transmission components?

- Steel round bars are a suitable choice for the fabrication of transmission components. Steel is extensively utilized in the manufacturing sector due to its exceptional strength, durability, and resistance to deterioration. In the production of transmission components like gears, shafts, and couplings, it is customary to employ round bars made of steel. These steel round bars are typically shaped through machining or forging and subsequently subjected to heat treatment to enhance their mechanical attributes. By utilizing steel round bars, the transmission components become capable of enduring substantial loads, facilitating seamless power transmission, and exhibiting an extended lifespan.

- Q: What is the tolerance for diameter and length of steel round bars?

- The tolerance of steel round bars' diameter and length may vary depending on industry standards and requirements. Typically, diameter tolerances are specified as a deviation, either positive or negative, from the nominal diameter. For example, a tolerance of +/- 0.005 inches implies that the actual diameter can deviate by up to 0.005 inches from the nominal diameter. Similarly, length tolerances are also expressed as a deviation, either positive or negative, from the nominal length. These tolerances can be indicated as a percentage or an absolute value. For instance, a tolerance of +/- 1% or +/- 0.5 inches means that the actual length can deviate by up to 1% of the nominal length or 0.5 inches, whichever is greater. It's worth noting that different industries may have diverse tolerance requirements depending on the specific applications and intended use of steel round bars. Hence, it is vital to refer to the relevant industry standards or consult with the manufacturer or supplier to determine the precise tolerance specifications for diameter and length in a specific context.

- Q: How strong are steel round bars compared to other materials?

- Steel round bars are known for their exceptional strength and durability, making them one of the strongest materials available. Compared to other materials such as aluminum, brass, and wood, steel round bars have a significantly higher tensile strength, which refers to the amount of pulling force a material can withstand without breaking. Steel round bars can also handle higher compressive loads, making them ideal for applications where heavy loads or pressure is involved. In addition to their high strength, steel round bars also exhibit excellent ductility, which means they can be easily shaped or bent without breaking. This characteristic makes steel round bars versatile and widely used in various industries such as construction, automotive, manufacturing, and aerospace. While other materials may have their own unique properties and applications, steel round bars remain a top choice when it comes to strength and reliability. Their ability to withstand high loads, resist deformation, and maintain structural integrity make them a popular choice for structural components, shafts, axles, and many other demanding applications.

- Q: How do steel round bars perform under vibration or resonance?

- Steel round bars have excellent performance under vibration or resonance due to their high strength and stiffness. They are able to withstand and absorb vibrations, minimizing the risk of failure or damage. Additionally, steel round bars possess good damping properties, which helps in dissipating energy and reducing the amplitude of vibrations, resulting in improved stability and reduced noise levels.

Send your message to us

Hot Rolled Steel Round Bar 6mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords