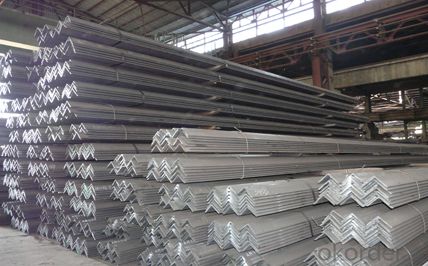

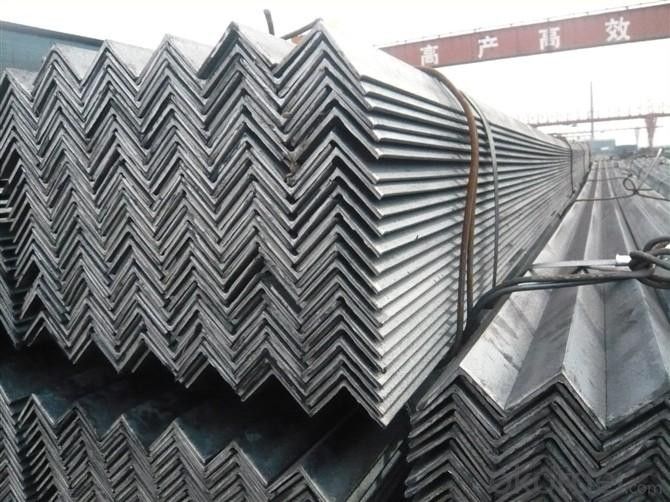

Equal Angle Steel Mild Steel for Infrastructure Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Equal Angle Steel Mild Steel for Infrastructure Project at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel Mild Steel for Infrastructure Project are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel Mild Steel for Infrastructure Project are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

| EQUAL ANGLE STEEL | |||||

| size(mm) | a(mm) | a1(mm) | thickness(mm) | kg/m | length |

| 50*50*4 | 50 | 50 | 4 | 3.059 | 6m,9m,12m |

| 50*50*5 | 50 | 50 | 5 | 3.77 | 6m,9m,12m |

| 50*50*6 | 50 | 50 | 6 | 4.465 | 6m,9m,12m |

| 63*63*5 | 63 | 63 | 5 | 4.822 | 6m,9m,12m |

| 63*63*6 | 63 | 63 | 6 | 5.721 | 6m,9m,12m |

| 65*65*5 | 65 | 65 | 5 | 5 | 6m,9m,12m |

| 65*65*6 | 65 | 65 | 6 | 5.91 | 6m,9m,12m |

| 65*65*8 | 65 | 65 | 8 | 7.66 | 6m,9m,12m |

| 75*75*5 | 75 | 75 | 5 | 5.818 | 6m,9m,12m |

| 75*75*6 | 75 | 75 | 6 | 6.905 | 6m,9m,12m |

| 75*75*8 | 75 | 75 | 8 | 9.03 | 6m,9m,12m |

| 75*75*9 | 75 | 75 | 9 | 9.96 | 6m,9m,12m |

| 75*75*10 | 75 | 75 | 10 | 11.089 | 6m,9m,12m |

| 80*80*6 | 80 | 80 | 6 | 7.375 | 6m,9m,12m |

| 80*80*7 | 80 | 80 | 7 | 8.525 | 6m,9m,12m |

| 80*80*8 | 80 | 80 | 8 | 9.658 | 6m,9m,12m |

| 80*80*10 | 80 | 80 | 10 | 11.874 | 6m,9m,12m |

| 90*90*6 | 90 | 90 | 6 | 8.35 | 6m,9m,12m |

| 90*90*7 | 90 | 90 | 7 | 9.656 | 6m,9m,12m |

| 90*90*8 | 90 | 90 | 8 | 10.946 | 6m,9m,12m |

| 90*90*10 | 90 | 90 | 10 | 13.476 | 6m,9m,12m |

| 100*100*6 | 100 | 100 | 6 | 9.366 | 6m,9m,12m |

| 100*100*7 | 100 | 100 | 7 | 10.83 | 6m,9m,12m |

| 100*100*8 | 100 | 100 | 8 | 12.276 | 6m,9m,12m |

| 100*100*9 | 100 | 100 | 9 | 13.49 | 6m,9m,12m |

| 100*100*10 | 100 | 100 | 10 | 15.12 | 6m,9m,12m |

| 100*100*12 | 100 | 100 | 12 | 17.898 | 6m,9m,12m |

| 120*120*8 | 120 | 120 | 8 | 14.88 | 6m,9m,12m |

| 120*120*10 | 120 | 120 | 10 | 18.37 | 6m,9m,12m |

| 120*120*12 | 120 | 120 | 12 | 21.66 | 6m,9m,12m |

| 125*125*8 | 125 | 125 | 8 | 15.504 | 6m,9m,12m |

| 125*125*10 | 125 | 125 | 10 | 19.133 | 6m,9m,12m |

| 125*125*12 | 125 | 125 | 12 | 22.696 | 6m,9m,12m |

| 130*130*10 | 130 | 130 | 10 | 19.8 | 6m,9m,12m |

| 130*130*12 | 130 | 130 | 12 | 23.6 | 6m,9m,12m |

| 130*130*13 | 130 | 130 | 13 | 25.4 | 6m,9m,12m |

| 130*130*14 | 130 | 130 | 14 | 27.2 | 6m,9m,12m |

| 150*150*10 | 150 | 150 | 10 | 23 | 6m,9m,12m |

| 150*150*12 | 150 | 150 | 12 | 27.3 | 6m,9m,12m |

| 150*150*14 | 150 | 150 | 14 | 31.6 | 6m,9m,12m |

| 150*150*15 | 150 | 150 | 15 | 33.8 | 6m,9m,12m |

| 140*140*10 | 140 | 140 | 10 | 21.49 | 6m,9m,12m |

| 140*140*12 | 140 | 140 | 12 | 25.52 | 6m,9m,12m |

| 140*140*14 | 140 | 140 | 14 | 29.49 | 6m,9m,12m |

| 160*160*10 | 160 | 160 | 10 | 24.73 | 6m,9m,12m |

| 160*160*12 | 160 | 160 | 12 | 29.39 | 6m,9m,12m |

| 160*160*14 | 160 | 160 | 14 | 33.99 | 6m,9m,12m |

| 180*180*12 | 180 | 180 | 12 | 33.16 | 6m,9m,12m |

| 180*180*14 | 180 | 180 | 14 | 39.39 | 6m,9m,12m |

| 180*180*16 | 180 | 180 | 16 | 43.45 | 6m,9m,12m |

| 180*180*18 | 180 | 180 | 18 | 48.63 | 6m,9m,12m |

| 200*200*14 | 200 | 200 | 14 | 42.89 | 6m,9m,12m |

| 200*200*16 | 200 | 200 | 16 | 48.68 | 6m,9m,12m |

| 200*200*18 | 200 | 200 | 18 | 54.4 | 6m,9m,12m |

| 200*200*20 | 200 | 200 | 20 | 60.06 | 6m,9m,12m |

| 200*200*24 | 200 | 200 | 24 | 71.17 | 6m,9m,12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: How do steel angles perform in terms of vibration resistance?

- Due to their robust and inflexible structure, steel angles generally exhibit excellent vibration resistance. The L-shaped configuration of a steel angle not only enhances its strength and stability but also grants it heightened resistance to vibrations. When utilized in construction or engineering endeavors, steel angles effectively absorb and mitigate vibrations, thereby minimizing the potential for structural damage or failure. The rigidity and notable tensile strength of steel angles enable them to withstand dynamic loads and vibrations stemming from diverse factors, such as wind, earthquakes, or machinery operations. They proficiently distribute and dissipate vibrational forces throughout their structure, averting excessive movement or oscillation. This proves particularly pivotal in applications requiring steadfastness and longevity, such as in the construction of bridges, buildings, or industrial equipment. Furthermore, steel angles can be tailored and fabricated to meet precise vibration resistance specifications. By selecting suitable steel grades and dimensions, engineers can optimize the performance of steel angles in terms of vibration resistance. They also possess the ability to incorporate supplementary characteristics like stiffeners or reinforcements, further augmenting the vibration resistance of steel angle structures. Collectively, steel angles have demonstrated their dependability and effectiveness in withstanding vibrations, rendering them a favored choice across a multitude of industries and applications where upholding structural integrity is of paramount importance.

- Q: Can steel angles be used in residential construction?

- Yes, steel angles can be used in residential construction. Steel angles are versatile structural elements that are commonly used in various construction applications, including residential buildings. They are often used for framing, reinforcing, and providing structural support in walls, roofs, and floors. Steel angles are preferred in residential construction due to their strength, durability, and ability to withstand heavy loads. They can be easily welded, bolted, or screwed into place, making them suitable for a wide range of construction projects. Additionally, steel angles can be galvanized or coated to enhance their resistance to corrosion, ensuring their longevity. Overall, steel angles are a reliable and cost-effective choice for residential construction.

- Q: How do you protect steel angles from moisture?

- Steel angles can be protected from moisture by applying a suitable coating or paint that acts as a barrier against moisture. Additionally, regular inspection and maintenance, including the removal of any rust or corrosion, can help prevent moisture damage.

- Q: Are steel angles suitable for earthquake-resistant structures?

- Steel angles are commonly used in earthquake-resistant structures due to their high strength and ductility properties. The angular shape of these structural members allows them to effectively resist lateral forces caused by seismic events. The ability of steel angles to absorb and dissipate energy during an earthquake makes them suitable for withstanding the dynamic loads generated by ground motions. Additionally, steel angles can be easily connected and joined together, providing a high level of structural integrity and ensuring the overall stability of the building. These factors make steel angles a favorable choice for earthquake-resistant structures, as they offer a reliable and durable solution for mitigating the impact of seismic events.

- Q: How are steel angles protected during transportation and storage?

- To ensure the preservation and quality of steel angles during transportation and storage, various measures are taken. One commonly employed method involves the application of a protective coating or paint to the surfaces of the steel angles. This coating acts as a barrier, shielding the angles from moisture and preventing the occurrence of rust and corrosion. Moreover, plastic wrapping or tarp covering can be utilized to safeguard the angles against dirt, dust, and other contaminants. During transportation, the risk of shifting or falling is minimized by securing the steel angles in bundles or arranging them in a manner that reduces such hazards. Additionally, pallets or skids may be employed to facilitate handling and prevent direct contact with the ground. When stored, it is crucial to keep the steel angles in a well-ventilated and dry area in order to prevent the accumulation of moisture. Furthermore, proper labeling and handling instructions play a vital role in preventing mishandling or damage during transportation. This entails the use of appropriate lifting equipment and avoidance of rough handling that could potentially lead to bending or deformation. By implementing these protective measures, the integrity and quality of steel angles can be upheld throughout the transportation and storage processes, ensuring their readiness for use.

- Q: What are the different methods of surface preparation for steel angles?

- Some of the different methods of surface preparation for steel angles include abrasive blasting, chemical cleaning, and mechanical cleaning. Abrasive blasting involves using a high-pressure stream of abrasive material to remove rust, scale, and other contaminants from the surface of the steel. Chemical cleaning involves using chemicals to dissolve and remove rust and other contaminants. Mechanical cleaning involves using tools such as wire brushes or sandpaper to physically scrape or scrub the surface of the steel to remove rust and other contaminants. These methods are important in preparing the steel surface for painting, coating, or other forms of protection against corrosion.

- Q: What are the different types of steel angles used in agricultural applications?

- There are several different types of steel angles commonly used in agricultural applications. 1. Equal Angle: This type of steel angle has equal sides and is often used for structural support in agricultural buildings, such as barns and sheds. It provides stability and strength, making it suitable for load-bearing applications. 2. Unequal Angle: As the name suggests, this steel angle has unequal sides, with one side longer than the other. It is commonly used in agricultural machinery, such as tractor attachments and implements. The unequal sides allow for better positioning and attachment of various components. 3. Lipped Angle: Lipped angles are similar to equal angles but have an additional lip or flange on one side. This lip provides added support and rigidity, making it ideal for agricultural applications that require extra strength, such as fencing and gate posts. 4. Slotted Angle: Slotted angles are versatile and can be adjusted to different angles as needed. They are commonly used in agricultural shelving systems, allowing farmers to create custom storage solutions for tools, equipment, and supplies. The slots in the angles provide flexibility for adjusting shelf heights. 5. Rolled Steel Angle: Rolled steel angles are produced by rolling steel into angle-shaped sections. They are commonly used in agricultural construction for bracing, supporting beams, and framing. Rolled steel angles offer high strength and durability, making them suitable for demanding agricultural environments. Each type of steel angle has its unique characteristics and advantages, and the choice depends on the specific agricultural application and the level of strength and support required. It is important to consider factors such as load-bearing capacity, durability, and resistance to corrosion when selecting the appropriate steel angle for agricultural use.

- Q: How are steel angles measured and specified?

- When it comes to steel angles, their dimensions and structural characteristics play a significant role in measurement and specification. The dimensions are determined by the length of the legs and the thickness of the material. The length of the legs refers to the vertical and horizontal sides of the angle, while the thickness represents the width. Expressing the dimensions of a steel angle can be done in two ways. One format is to state the length of the legs followed by the thickness, while the other format is to mention the thickness first and then the length of the legs. For example, an angle with legs measuring 2 inches and a thickness of 1/4 inch can be specified as 2" x 2" x 1/4" or 1/4" x 2" x 2". Apart from the dimensions, the structural characteristics of steel angles are also used for specification. This includes indicating the type of steel used, such as carbon steel or stainless steel, as well as mentioning the angle's load-bearing capacity and resistance to corrosion. Steel angles find extensive use in construction, manufacturing, and various industrial applications. They serve multiple purposes, such as providing structural support, acting as reinforcements, or serving as framing elements. By having a clear understanding of how steel angles are measured and specified, architects, engineers, and builders can effectively choose and utilize the appropriate angles for their projects.

- Q: Can steel angles be used in industrial or heavy-duty applications?

- Yes, steel angles can be widely used in industrial or heavy-duty applications due to their high strength, durability, and versatility. They are commonly utilized in construction, infrastructure, manufacturing, and fabrication industries for various purposes such as supporting structures, framing, bracing, and reinforcement. Their ability to withstand heavy loads and provide stability makes them suitable for demanding environments where strength and resilience are crucial.

Send your message to us

Equal Angle Steel Mild Steel for Infrastructure Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords