Mild Steel Double T Equivalent to I Beam Small and Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Mild Steel Double T Equivalent to I Beam Description:

Mild steel double T equivalent to I beam is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Mild steel double T equivalent to I beam is usually made of structural steel and is used in construction and civil engineering. The mild steel double T equivalent to I beam resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Mild steel double T equivalent to I beam theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam Bar IPE Images:

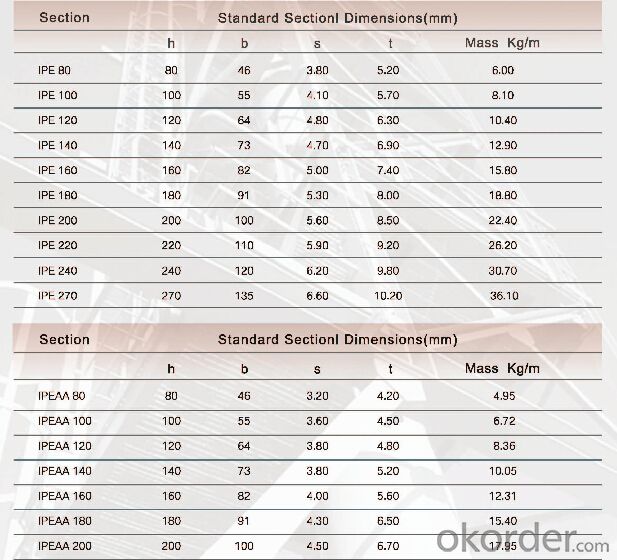

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How long is the installation specification for the cantilever platform?

- The feeling should be as much as 1.25 times the cantilever length of the overhanging scaffolding, but actually the overhang is already very long and the anchor is not enough on the floor according to the theoretical value. We have not fixed the steel ring, so we have to pull it by wire rope, and there is skid resistant steel underneath.

- Q: How do steel I-beams perform in areas with high humidity?

- Areas with high humidity are well-suited for the use of steel I-beams. Steel possesses excellent resistance to moisture and is not prone to rust or corrosion. However, it is crucial to guarantee adequate maintenance and protection to avoid any potential problems. To accomplish this, applying protective coatings or paint to the steel beams is recommended, as they serve as a barrier against moisture. Moreover, conducting regular inspections and cleanings aids in detecting and resolving any indications of corrosion or damage. All in all, steel I-beams are a dependable and long-lasting option for areas with high humidity, as long as they receive proper care and maintenance.

- Q: How do steel I-beams perform in areas with high salinity or corrosive environments?

- Steel I-beams can perform well in areas with high salinity or corrosive environments, particularly if they are properly protected and maintained. High salinity and corrosive environments, such as coastal regions or industrial areas, can accelerate the corrosion process and potentially compromise the structural integrity of steel. To mitigate the effects of high salinity and corrosion, steel I-beams are often coated with protective materials such as galvanized coatings, epoxy coatings, or specialized paint systems. These coatings act as a barrier, preventing direct contact between the steel and the corrosive elements. Regular inspections and maintenance are also essential to identify and address any signs of corrosion early on. However, it is important to note that even with protective coatings, the lifespan of steel I-beams in high salinity or corrosive environments may be reduced compared to those in less corrosive environments. The severity of the environment, the quality of the coatings, and the maintenance practices all play a crucial role in determining the performance and longevity of steel I-beams in such conditions. In particularly harsh environments, alternative materials such as stainless steel or fiberglass-reinforced polymers (FRP) may be considered as they are inherently more resistant to corrosion. These materials offer extended durability and are often used in marine structures or other applications where corrosive conditions are prevalent. Overall, steel I-beams can still be a viable option in areas with high salinity or corrosive environments, provided that appropriate protective measures are taken and regular maintenance is carried out. Consulting with structural engineers or corrosion specialists can help determine the most suitable approach to ensure the long-term performance and safety of steel I-beams in such conditions.

- Q: Can steel I-beams be used for sports stadiums?

- Indeed, sports stadiums can utilize steel I-beams. Renowned for their structural integrity and load-bearing capabilities, steel I-beams are widely employed in the construction sector. Their impressive strength-to-weight ratio enables the creation of expansive and unobstructed areas, eliminating the necessity for excessive columns or supports. Consequently, they prove to be an optimal selection for sports stadiums, which demand vast spans and open spaces to accommodate numerous spectators. Moreover, steel I-beams can be readily fabricated and tailored to meet the precise design specifications of a sports stadium, guaranteeing both structural stability and safety.

- Q: What is the allowable stress for 40B I-beam?

- Ordinary I-beam, light I-beam flange is variable cross-section, by web plate thickness, external thin; H steel: HW, HM, HN, HEA, HEB, HEM and so onOrdinary I-beam, lightweight I-beam has formed the national standard, the common 10# I-beam is equivalent to the Internet I100 (such as 10# also channel equivalent channel (U100) for the implementation of the standards of different countries, which have subtle differences in their specifications)

- Q: Are steel I-beams suitable for load-bearing walls?

- No, steel I-beams are typically not suitable for load-bearing walls. They are primarily used as horizontal structural members to support beams or joists, not for vertical support. Load-bearing walls usually require more robust construction methods such as concrete or masonry.

- Q: Are there any limitations to the depth of steel I-beams?

- Yes, there are limitations to the depth of steel I-beams. The depth of an I-beam is typically limited by practical manufacturing constraints and the requirements of the specific application. As the depth increases, the weight and cost of the beam also increase. Additionally, there may be limitations based on the available space or height restrictions in the construction project. Ultimately, the depth of steel I-beams is determined by a combination of structural, economic, and practical considerations.

- Q: I took 20 overhanging scaffolding difficult to take the highest. How many meters height

- I took 20 overhanging scaffolding difficult to take a maximum height of 20 meters.

- Q: How do you determine the spacing and placement of steel I-beams in a structure?

- Determining the spacing and placement of steel I-beams in a structure is a complex process that requires careful analysis and consideration of multiple factors. These factors encompass the load-bearing requirements, beam span, type of structure, and adherence to building codes and regulations. To begin, the anticipated load that the beams will bear must be calculated. This involves assessing the permanent weight of the structure (dead loads), temporary weight such as furniture, people, and equipment (live loads), and any other specific loads imposed on the structure. By determining the load requirements, engineers can select the appropriate beam size and strength. After establishing the load requirements, the span of the beams needs to be determined. The span refers to the distance between the supports or columns where the beams will be placed. Longer spans necessitate stronger and larger beams to ensure structural integrity and prevent deflection or sagging. Once the load requirements and span are known, the structural engineer can consult building codes and regulations to ascertain the maximum allowable deflection and bending stress limits for the specific application. These codes provide guidelines for the maximum allowable spacing between beams and the minimum size or depth of the beams based on the loads and span. Beyond technical considerations, the type of structure also influences beam spacing and placement. In residential construction, beams are typically spaced at regular intervals along the length of the structure to support the floor and roof loads. However, in industrial or commercial buildings, the placement of beams may be influenced by the layout of the space, equipment, or specific architectural requirements. Engineers often utilize computer-aided design (CAD) software and structural analysis programs to optimize beam spacing and placement. These tools enable them to simulate various load scenarios and analyze the structural behavior of the beams. Through this process, adjustments and refinements can be made to ensure an efficient and safe design. In conclusion, determining the spacing and placement of steel I-beams in a structure requires a meticulous analysis of load requirements, span, building codes, and structural considerations. By carefully considering these factors, engineers can determine the ideal arrangement to achieve a strong, safe, and efficient structural design.

- Q: Can steel I-beams be used in healthcare or hospital construction?

- Yes, steel I-beams can be and are commonly used in healthcare or hospital construction. They provide structural support and are often used in the framework of the building to withstand heavy loads and ensure the safety and stability of the structure.

Send your message to us

Mild Steel Double T Equivalent to I Beam Small and Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords