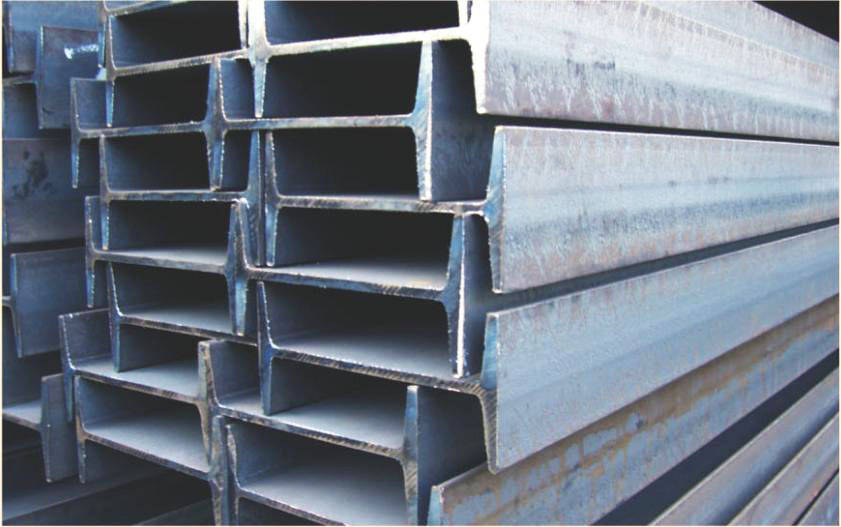

Mild Steel I-Beam Steel Profiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Mild Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Mild Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Brand: Jinding

Grade: SS400 – SS490

Standard: JIS, ASTM, GB

Packaging: Export packing, nude packing, bundled

Place of Origin: Hebei, China

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How is a steel I-beam different from other types of beams?

- A steel I-beam, also known as a universal beam or H-beam, is different from other types of beams primarily due to its unique shape and structural properties. Unlike traditional rectangular or square-shaped beams, an I-beam is shaped like the letter "I," with a central vertical web and two horizontal flanges on either side. One key advantage of the I-beam design is its high strength-to-weight ratio. The vertical web provides excellent resistance to bending, while the horizontal flanges help distribute the load evenly along the length of the beam. This allows I-beams to carry heavy loads over long spans without excessive deflection or deformation. Additionally, the I-beam's unique shape makes it ideal for construction applications where wide-spanning and load-bearing capacities are required. It is commonly used in structural steel frames, bridges, and large building projects. The design allows for effective load distribution, making it possible to support heavy loads and withstand dynamic forces such as wind and earthquakes. Compared to other types of beams, such as wooden beams or concrete beams, steel I-beams offer several advantages. Steel is known for its exceptional strength and durability, making it capable of withstanding extreme loads and harsh environmental conditions. It is also fire-resistant, making it a safer choice for structures. Moreover, steel I-beams are highly customizable and versatile. They can be fabricated in various sizes and lengths to suit specific project requirements. Additionally, they can be easily joined or bolted together to create longer spans or complex structures. This flexibility allows for efficient construction, reducing labor and material costs. In summary, the steel I-beam stands out from other beams due to its distinctive shape and superior strength-to-weight ratio. Its design allows for efficient load distribution and makes it suitable for heavy-duty applications. With excellent durability and customization options, steel I-beams are a preferred choice in the construction industry.

- Q: How long is a ton of 10# I-beam?

- 10# I-beam is 10.007KG/ meters in weight and 99.930 meters in weight. 10# I-beam is 6 meters per foot. There is a need to call 029-89104110 calls, say you are Baidu, know the questioner, give you discount.

- Q: What are the common loadings and forces that steel I-beams need to withstand?

- Steel I-beams are commonly used in construction and engineering projects due to their strength and load-bearing capabilities. They are designed to withstand various loads and forces to ensure the stability and integrity of the structure they are supporting. Some of the common loadings and forces that steel I-beams need to withstand include: 1. Dead Load: This refers to the weight of the structure itself, including the weight of the steel beam and any other permanent materials or components. Steel I-beams are designed to bear the dead load without experiencing excessive deflection or deformation. 2. Live Load: Live loads are temporary loads that can vary in magnitude and location. Examples include people, furniture, equipment, and vehicles. Steel I-beams are engineered to support these dynamic loads and distribute them evenly to prevent overloading. 3. Wind Load: Buildings and structures are subjected to wind forces, which can exert significant pressure on the steel I-beams. The design of I-beams considers wind speed, building height, and the shape of the structure to ensure they can withstand these lateral forces without failure. 4. Snow Load: In areas with heavy snowfall, steel I-beams must be able to withstand the weight of accumulated snow on the roof or other horizontal surfaces. The design takes into account the estimated weight of snow and distributes it across the beam to avoid excessive deflection or collapse. 5. Seismic Load: Earthquakes generate powerful seismic forces that can cause significant structural damage if not properly accounted for. Steel I-beams are designed to withstand these forces by incorporating seismic-resistant features such as high-strength connections and bracing systems. 6. Impact Load: In certain applications, steel I-beams may need to withstand impact forces, such as those caused by falling objects or collisions. These beams are designed with additional reinforcement to absorb and distribute the impact energy, preventing structural failure. 7. Temperature Load: Steel expands and contracts with temperature fluctuations. Steel I-beams must be able to handle thermal expansion and contraction to avoid stress-induced failures. Additionally, they may be exposed to high temperatures in industrial settings, which require special consideration in their design. Overall, steel I-beams are engineered to withstand a wide range of loadings and forces, ensuring the structural stability and safety of the buildings and structures they support.

- Q: What are the common applications of steel I-beams in commercial construction?

- Steel I-beams are commonly used in commercial construction for a variety of applications, including providing structural support for buildings, bridges, and other large structures. They are ideal for heavy loads and long spans, making them suitable for constructing floors, roofs, and walls. Additionally, steel I-beams are often used in the construction of mezzanines, platforms, and staircases, providing stability and durability.

- Q: What are the common welding techniques used for steel I-beams?

- The common welding techniques used for steel I-beams include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). These methods ensure strong and secure welds between the different sections of the I-beams, allowing them to withstand heavy loads and maintain structural integrity.

- Q: How do engineers determine the appropriate size of Steel I-Beams for a project?

- Engineers determine the appropriate size of Steel I-Beams for a project by considering a variety of factors. Firstly, they assess the load that the I-Beam will need to support. This includes both the dead load, which refers to the weight of the structure itself, and the live load, which includes any additional weight that the structure may be subjected to, such as equipment or occupants. Next, engineers consider the span of the beam, which is the distance between its supports. The longer the span, the larger the I-Beam will need to be in order to ensure sufficient strength and stability. Additionally, engineers take into account the deflection criteria, which refers to the maximum amount of bending or sagging that the beam can undergo under the anticipated loads. This helps determine the required stiffness of the I-Beam. Another critical factor that engineers consider is the material properties of the steel. They evaluate the yield strength and tensile strength of the steel to ensure that the selected I-Beam can withstand the loads without experiencing permanent deformation or failure. The steel's properties also affect the beam's weight, which can impact the overall design and construction costs. Engineers also take into account any specific building codes and regulations that govern the project. These codes often provide guidelines and specifications for the appropriate size and design of structural members like I-Beams. To determine the appropriate size of the I-Beam, engineers use mathematical calculations and structural analysis software. They apply principles of structural mechanics and utilize formulas such as moment distribution, shear force, and bending moment equations. These calculations help engineers determine the required section modulus and moment of inertia, which are essential parameters in selecting the appropriate I-Beam size. Additionally, engineers may consider practical considerations such as the availability and cost of standard I-Beam sizes. They aim to find a balance between the desired structural performance and the most economical and readily available options. Overall, the process of determining the appropriate size of Steel I-Beams for a project involves a comprehensive analysis of load requirements, span length, deflection criteria, material properties, building codes, and cost considerations. By considering all these factors, engineers can ensure the safe and efficient design of structures using Steel I-Beams.

- Q: Are steel I-beams affected by vibrations?

- Yes, steel I-beams can be affected by vibrations. Vibrations can cause the beams to resonate, leading to fatigue and potential failure over time. It is important to consider the frequency, amplitude, and duration of vibrations when designing structures with steel I-beams to ensure their stability and durability.

- Q: Can Steel I-Beams be painted or coated for corrosion protection?

- Steel I-beams can undergo painting or coating in order to protect against corrosion. This is a common practice to increase their durability and prevent deterioration. The application of paint or coating serves as a safeguarding layer, shielding the steel surface from moisture, chemicals, and other corrosive elements. This aids in extending the lifespan of the I-beams and preserving their structural integrity. Furthermore, the paint or coating also offers the advantage of allowing customization through various colors or finishes, enhancing the aesthetic appeal. It is crucial to ensure the use of appropriate painting or coating materials, as different types may offer varying degrees of protection and compatibility with steel surfaces.

- Q: What are the maximum and minimum lengths available for steel I-beams?

- The maximum and minimum lengths available for steel I-beams vary depending on the manufacturer and the specific requirements. However, typically, the maximum length of a steel I-beam is around 60 feet, while the minimum length can be as short as a few feet.

- Q: What is the influence of steel column on column?

- But the structure of bearing system of bare concrete column is not to wear steel door type, the problem is at the support beam of the local stress without good dispersion over; the node not only confined encryption, but was cut off steel stirrups.

Send your message to us

Mild Steel I-Beam Steel Profiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords