Steel Beam Sizes

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

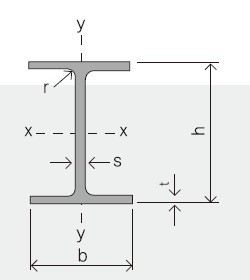

Specifications of Steel Beam Sizes

1. Product name: Steel Beam

2. Standard: EN10025, GB Standard, ASTM, JIS etc.

3. Grade: Q235B, A36, S235JR, Q345, SS400 or other equivalent.

4. Length: 5.8M, 6M, 9M, 10M, 12M or as your requirements

Steel Beam Sizes

|

Section |

Standard Sectional Dimensions(mm) | ||||

|

|

h |

b |

s |

t |

Mass Kg/m |

|

IPE80 |

80 |

46 |

3.80 |

5.20 |

6.00 |

|

IPE100 |

100 |

55 |

4.10 |

5.70 |

8.10 |

|

IPE120 |

120 |

64 |

4.80 |

6.30 |

10.40 |

|

IPE140 |

140 |

73 |

4.70 |

6.90 |

12.90 |

|

IPE160 |

160 |

82 |

5.00 |

7.40 |

15.80 |

|

IPE180 |

180 |

91 |

5.30 |

8.00 |

18.80 |

|

IPE200 |

200 |

100 |

5.60 |

8.50 |

22.40 |

|

IPE220 |

220 |

110 |

5.90 |

9.20 |

26.20 |

|

IPE240 |

240 |

120 |

6.20 |

9.80 |

30.70 |

|

IPE270 |

270 |

135 |

6.60 |

10.20 |

36.10 |

|

IPEAA80 |

80 |

46 |

3.20 |

4.20 |

4.95 |

|

IPEAA100 |

100 |

55 |

3.60 |

4.50 |

6.72 |

|

IPEAA120 |

120 |

64 |

3.80 |

4.80 |

8.36 |

|

IPEAA140 |

140 |

73 |

3.80 |

5.20 |

10.05 |

|

IPEAA160 |

160 |

82 |

4.00 |

5.60 |

12.31 |

|

IPEAA180 |

180 |

91 |

4.30 |

6.50 |

15.40 |

|

IPEAA200 |

200 |

100 |

4.50 |

6.70 |

17.95 |

Applications of Steel Beam Sizes

Steel Beams are widely used used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packing & Delivery Terms of Steel Beam Sizes

1. Package: All the IPE/IPEAA Beam Steel will be tired by wire rod in bundles

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Shipment: In containers or in bulk cargo

6. Delivery time: All the IPE/IPEAA Beam Steel will be at the port of the shipment within 45 days after receiving the L/C at sight ot the advance pyment.

7. Payment: L/C at sight; 30% advance payment before production, 70% before shipment by T/T, etc.

Production flow of Steel Beam Sizes

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can Steel I-Beams be used for basement construction?

- Yes, Steel I-Beams can be used for basement construction. They are commonly used as load-bearing members to support the weight of the structure and transfer the loads to the foundation. Steel I-Beams provide strength, durability, and flexibility in basement construction, making them an ideal choice for supporting the structure above.

- Q: Can steel I-beams be used in theater stage construction?

- Certainly, theater stage construction can incorporate steel I-beams. These I-beams offer robust structural reinforcement, rendering them appropriate for expansive theater stages and platforms. They possess the capacity to endure substantial weights, such as sets, props, and equipment, thereby guaranteeing stage safety and stability. Moreover, steel I-beams can be readily tailored and manufactured to comply with precise design specifications, enabling flexibility in stage construction. Given their enduring nature and extended lifespan, they have gained popularity in theater stage construction as they can withstand the rigors of frequent use and lay a firm groundwork for diverse performances and productions.

- Q: Can steel I-beams be used in mezzanine or elevated platform construction?

- Yes, steel I-beams can be used in mezzanine or elevated platform construction. They provide structural support and stability, making them a common choice for such applications.

- Q: Are steel I-beams resistant to termites?

- Steel I-beams possess a remarkable resistance to termites. In contrast to wood, termites do not find steel appetizing, thus it does not entice or nourish them. This renders steel I-beams a superb option for construction projects in termite-infested regions, as they remain impervious to termite-induced harm.

- Q: How do you determine the appropriate size of a steel I-beam for a specific application?

- Determining the suitable dimensions of a steel I-beam for a particular usage involves taking into account various factors, such as the load requirements, span length, and structural design considerations. The following are the steps to determine the appropriate size of a steel I-beam: 1. Calculate the load requirements: Begin by computing the total load that the I-beam must bear. This includes the weight of the structure or equipment it supports, as well as any additional live or dynamic loads present. 2. Evaluate the span length: The span length refers to the distance between the supports on which the I-beam rests. The longer the span, the higher the bending moment and deflection the beam will experience. Hence, it is crucial to consider the span length to choose a suitable size capable of handling the expected load without excessive deflection. 3. Refer to structural design codes: Consult local building codes, engineering standards, and structural design handbooks to determine the required safety factors, allowable stress limits, and deflection limits. These codes provide guidelines and formulas to calculate the necessary size of the I-beam based on the expected loads and span length. 4. Analyze the loading conditions: Consider the type of load applied to the I-beam, such as point loads, uniformly distributed loads, or concentrated loads. Analyze the loading conditions to determine the maximum bending moment, shear force, and deflection the beam will experience. This analysis aids in selecting the appropriate size of the I-beam capable of safely handling these loads. 5. Select the suitable steel grade: Steel I-beams are available in different grades, including A36, A572, and A992, each with distinct mechanical properties. Choose the appropriate steel grade based on the required strength and stiffness for the application. Factors such as required corrosion resistance or fire resistance may also influence this choice. 6. Employ structural analysis software: For complex applications, it may be advantageous to utilize structural analysis software to accurately determine the required size of the I-beam. These software programs can perform detailed calculations and simulations to ensure that the chosen I-beam meets the structural requirements. 7. Seek advice from a structural engineer: If uncertain about the appropriate size of the I-beam for a specific application, it is advisable to consult with a structural engineer. They can provide expertise and conduct a thorough analysis to determine the most suitable size and design for the I-beam. By considering these steps and factors, one can determine the appropriate size of a steel I-beam that can safely and effectively support the load requirements for a specific application.

- Q: Can steel I-beams be used in both residential and commercial buildings?

- Yes, steel I-beams can be used in both residential and commercial buildings. Steel I-beams are commonly used as structural supports due to their strength, durability, and versatility. They provide excellent load-bearing capabilities, allowing for the construction of large spans and open floor plans. In residential buildings, steel I-beams are often used to support the weight of upper floors and roof structures. In commercial buildings, they are frequently employed in the construction of warehouses, factories, and high-rise buildings. The use of steel I-beams ensures the structural integrity of the building, making them suitable for various applications in both residential and commercial settings.

- Q: Does the 22# B I-beam length not need to overlap, local patches can find what standard?

- You don't know the temperature here said the bar where there is no temperature, upper beam reinforcement, roof panel is generally no upper reinforcement area, consideration of temperature shrinkage cracking and reinforcement plate set temperature, temperature stress and reinforcement lap length of reinforcement and their own Ll

- Q: What are the load-bearing capacity of rectangular and I-beam steel sections of the same size?

- In the same section size, the web and wing plate of I-beam are higher than rectangular steel, so the modulus of bending section is also high.

- Q: What are the considerations for fire rating steel I-beams?

- When it comes to fire rating steel I-beams, there are several considerations that need to be taken into account. First and foremost, the fire resistance of the I-beams is a crucial factor. This is determined by the type and thickness of the fireproofing material applied to the beams. Common fireproofing materials for steel I-beams include intumescent coatings, which expand when exposed to heat, forming an insulating layer that protects the steel from fire. The fire resistance rating of the I-beams should meet the requirements set by local building codes and regulations. Another consideration is the load-bearing capacity of the I-beams during a fire. Steel I-beams are designed to carry heavy loads, but the high temperatures in a fire can weaken the structural integrity of the steel. Therefore, it is essential to ensure that the I-beams can withstand both the weight loads and the potential impact of a fire without compromising their stability. The fire protection system in the building should also be considered. This includes the presence of fire alarms, sprinklers, and other fire suppression systems that can help control or extinguish a fire. These systems can provide additional protection to the steel I-beams and prevent the fire from spreading further. Furthermore, the surrounding materials and construction of the building need to be taken into account. The fire rating of the steel I-beams should be compatible with the fire resistance of other building components, such as walls, floors, and ceilings. If the I-beams are supporting these components, they should have a fire rating that matches or exceeds the fire rating of the surrounding materials. Lastly, it is vital to consider the intended use and occupancy of the building. Different occupancy types have different fire safety requirements, and these requirements may influence the fire rating needed for the steel I-beams. For example, buildings with high occupancy loads or those housing flammable materials may require higher fire resistance ratings for the I-beams. Overall, when considering fire rating steel I-beams, factors such as fire resistance, load-bearing capacity, fire protection systems, building construction, and occupancy type should all be carefully evaluated to ensure the safety and compliance of the structure.

- Q: How do steel I-beams perform in areas with high pollution or chemical exposure?

- Steel I-beams are known for their durability and strength, making them a popular choice for construction projects in various environments. However, in areas with high pollution or chemical exposure, the performance of steel I-beams can be significantly affected. High pollution levels, such as airborne pollutants or corrosive gases, can cause corrosion and degradation of the steel surface. If left untreated, this corrosion can weaken the structural integrity of the I-beams over time. Additionally, chemical exposure, especially to acids or other corrosive substances, can accelerate the corrosion process and further compromise the strength of the steel. To mitigate the impact of high pollution or chemical exposure, several measures can be taken. One common approach is to apply protective coatings to the surface of the I-beams. These coatings act as a barrier, preventing direct contact between the steel and the pollutants or chemicals. Additionally, these coatings can provide resistance against corrosion and extend the lifespan of the I-beams. Another approach is to use stainless steel I-beams, which contain a higher amount of chromium and nickel. This composition makes stainless steel highly resistant to corrosion and chemical exposure. Although stainless steel I-beams are more expensive than regular steel, they are a worthwhile investment in areas with high pollution or chemical exposure. Regular maintenance and cleaning are also essential to ensure the long-term performance of steel I-beams in such environments. Regular inspections can help identify any signs of corrosion or degradation early on, allowing for timely repairs or replacements. In conclusion, while steel I-beams are generally durable, their performance in areas with high pollution or chemical exposure can be compromised. Protective coatings, the use of stainless steel, and regular maintenance are key factors to consider in order to ensure the optimal performance and longevity of steel I-beams in these challenging environments.

1. Manufacturer Overview

| Location | Qinhuangdao, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Mid East; Africa; Southeast Asia; Brazil |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 400,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Steel Beam Sizes

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords