Steel I Beam IPE in Chinese Standard and European Standard for Asia and Africa

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel I Beam IPE Description:

Steel I beam IPE is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel I beam IPE is usually made of structural steel and is used in construction and civil engineering. The Steel I beam IPE resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel I beam IPE theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam IPE:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam IPE Images:

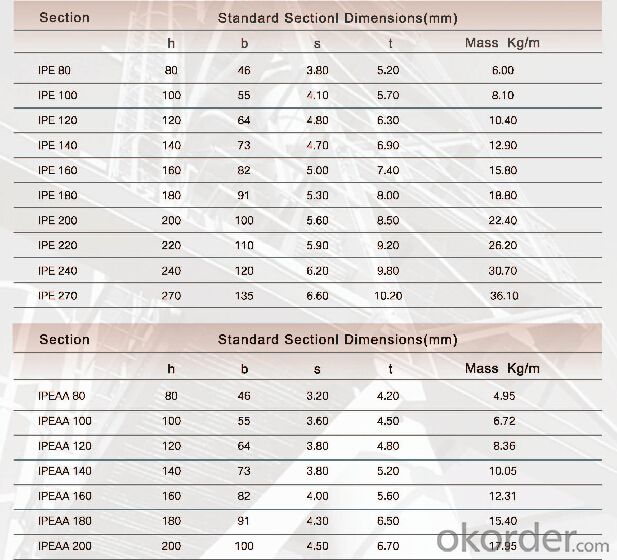

4. Steel I Beam IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: What are the common methods of connecting steel I-beams to concrete structures?

- There are several common methods of connecting steel I-beams to concrete structures. The choice of method depends on various factors such as the load requirements, the design of the structure, and the specific project requirements. Some of the most commonly used methods include: 1. Embedment: This method involves embedding the ends of the steel I-beams directly into the concrete structure. The beams are placed in the desired location and then concrete is poured around them, completely encasing the ends. This provides a strong and stable connection between the steel beams and the concrete structure. 2. Welding: Welding is another commonly used method for connecting steel I-beams to concrete structures. In this method, steel plates or brackets are welded to the ends of the beams, and these plates are then embedded or bolted into the concrete. Welding provides a strong and durable connection, and it is often used in high-load applications. 3. Bolting: Bolting is a versatile method that is frequently used for connecting steel I-beams to concrete structures. Steel plates or brackets with pre-drilled holes are attached to the ends of the beams, and these plates are then bolted to the concrete using anchor bolts. This method allows for easy installation and disassembly, making it suitable for temporary structures or applications that require frequent modifications. 4. Epoxy adhesive: Epoxy adhesive is commonly used for connecting steel I-beams to concrete structures where drilling or welding is not desired or feasible. In this method, steel plates or brackets are bonded to the concrete using epoxy adhesive, creating a strong and reliable connection. Epoxy adhesive is particularly useful in situations where there are aesthetic concerns, as it provides a clean and seamless connection. 5. Mechanical connectors: Mechanical connectors, such as steel clamps or brackets, are often used to connect steel I-beams to concrete structures. These connectors are designed to provide a secure and adjustable connection, allowing for easy installation and alignment of the beams. Mechanical connectors are typically used in applications where flexibility and adjustability are required. It is important to note that the specific method of connecting steel I-beams to concrete structures may vary depending on the project requirements, local building codes, and engineering recommendations. Consulting with a structural engineer or a professional in the field is crucial to ensure the appropriate method is chosen for a specific project.

- Q: Elevator room in the cement blocks is what to do for?

- Is used to work beam bearing all the weight of the elevator traction machine.

- Q: What are the transportation and handling considerations for steel I-beams?

- Transportation and handling considerations for steel I-beams are crucial to ensure the safety of both the materials and the individuals involved. Here are some important points to consider: 1. Equipment: Steel I-beams are heavy and require specialized equipment for transportation. Cranes, forklifts, or other lifting devices should be used to handle and move the beams safely. It is essential to ensure that the equipment used is suitable for the weight and size of the beams. 2. Secure Packaging: Proper packaging and securing of steel I-beams are necessary to prevent damage during transportation. The beams should be adequately wrapped, strapped, or secured to prevent shifting, rolling, or falling during transit. This helps to protect the beams from scratches, dents, or any other form of physical damage. 3. Weight Distribution: When loading the steel I-beams onto a truck or any other means of transportation, it is important to distribute the weight evenly. Uneven weight distribution can cause instability during transportation, potentially leading to accidents or damage to the beams. 4. Handling Precautions: Care should be taken when handling steel I-beams to avoid injuries. Workers should be trained on proper lifting techniques and should wear appropriate personal protective equipment (PPE) such as gloves, safety boots, and helmets. It is also recommended to have a team of trained individuals to assist in the handling process. 5. Route Planning: Before transporting steel I-beams, it is important to plan the route carefully. Considerations such as road conditions, bridge weight limits, and height restrictions should be taken into account to ensure a smooth and safe journey. In some cases, it may be necessary to obtain permits or escorts to comply with local regulations. 6. Weather Conditions: Weather conditions can affect the transportation and handling of steel I-beams. Extreme weather conditions like strong winds, heavy rain, or snow can pose additional risks. It is important to monitor weather forecasts and make necessary adjustments to the transportation plan to minimize potential hazards. 7. Storage: If there is a need to store steel I-beams temporarily, it is crucial to keep them in a clean, dry, and well-ventilated area. Storing them on a flat surface, preferably on wooden or rubber blocks, can help prevent damage from moisture, rust, or contact with the ground. By considering these transportation and handling considerations, the risk of damage, accidents, and injuries can be minimized, ensuring the safe delivery and use of steel I-beams.

- Q: How do you calculate the deflection of a steel I-beam?

- To calculate the deflection of a steel I-beam, you would need to consider factors such as the beam's dimensions, material properties, and load applied. Using mathematical equations and formulas, typically derived from Euler-Bernoulli beam theory, you can determine the deflection by considering the beam's moment of inertia, Young's modulus, and applied load. It is advisable to consult relevant engineering manuals or use specialized software for accurate calculations.

- Q: How do steel I-beams perform in areas with high seismic activity?

- Steel I-beams perform well in areas with high seismic activity due to their structural properties. I-beams are known for their strength, stiffness, and ability to resist lateral forces, making them suitable for seismic zones. The inherent rigidity of steel helps to distribute seismic forces throughout the structure, reducing the risk of collapse during an earthquake. Additionally, steel I-beams can be designed and reinforced to withstand specific seismic loads, ensuring the safety and stability of buildings in such areas.

- Q: What are the design considerations for steel I-beams in limited access areas?

- There are several key design considerations for steel I-beams in limited access areas. Firstly, the size and weight of the I-beams must be carefully determined to ensure they can be safely transported and maneuvered into the confined space. Additionally, the beams must be designed to withstand any potential loadings or forces that may be encountered during installation or use. The structural integrity of the surrounding area must also be evaluated to ensure it can support the weight of the beams. Finally, considerations must be made for any necessary modifications or adaptations to the beams to accommodate the restricted access, such as bolted connections or prefabricated sections.

- Q: How do you calculate the moment due to torsion in a steel I-beam?

- To calculate the moment due to torsion in a steel I-beam, you need to determine the shear stress and the polar moment of inertia. The shear stress can be found by dividing the applied torque by the polar moment of inertia. The polar moment of inertia can be calculated by summing the contributions of the individual components of the I-beam.

- Q: Are steel I-beams resistant to UV radiation?

- Steel I-beams are generally not resistant to UV radiation. UV radiation can cause steel to oxidize and corrode over time. This can lead to weakening of the structural integrity of the I-beams. To protect against UV radiation, steel I-beams are often coated with a protective layer such as paint or galvanization. These coatings act as a barrier, preventing direct exposure of the steel to UV radiation and reducing the risk of corrosion. However, over time, these coatings may degrade and require maintenance or reapplication to ensure continued protection against UV radiation.

- Q: What span is the maximum span for I-beam?

- Steel beams as beams, the maximum span should not exceed 7 meters, if the span is now large, the bottom must be propped up with pillars.

- Q: Can steel I-beams be used for both residential and commercial construction?

- Yes, steel I-beams can be used for both residential and commercial construction. Steel I-beams are known for their strength and durability, making them suitable for a wide range of construction applications. In residential construction, steel I-beams are commonly used for supporting load-bearing walls, floors, and roofs. They are also frequently used in commercial construction for large-scale structures such as warehouses, factories, and high-rise buildings. The versatility of steel I-beams allows architects and engineers to design and construct buildings of various sizes and types, making them a popular choice in both residential and commercial projects.

Send your message to us

Steel I Beam IPE in Chinese Standard and European Standard for Asia and Africa

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords