Hot Rolled I-Beam Steel with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

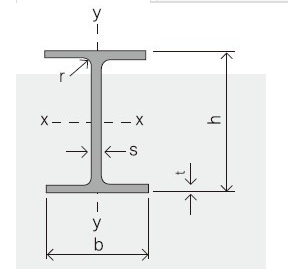

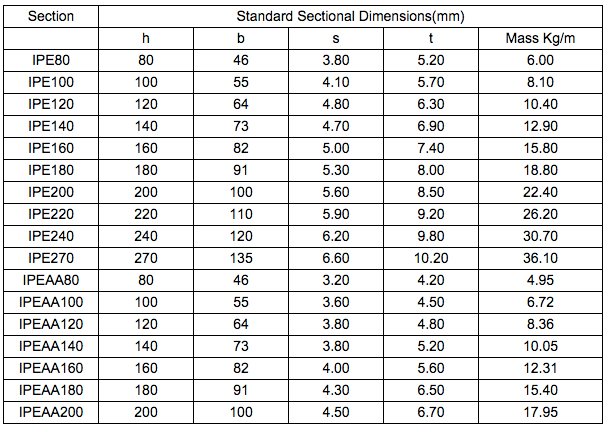

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

Q3: What is the normal tolerance of your steel products ?

A3: Normally 7%-9%, but we can also produce the goods according to the customers' requests.

Images:

- Q: What are the different types of steel I-beam profiles available?

- There are several different types of steel I-beam profiles available, including standard, wide flange, and H-beam. Standard I-beams have a tapered flange, while wide flange I-beams have a wider flange and are often used in larger structural applications. H-beams have a wider flange than standard I-beams and are commonly used in construction projects that require a high load-bearing capacity.

- Q: What are the common connections details for steel I-beams?

- The common connection details for steel I-beams include welding, bolting, and using various types of connectors such as clevises, gusset plates, and end plates. These connection methods ensure that the I-beams are securely joined together to form a strong and rigid structural system.

- Q: Can Steel I-Beams be used for wastewater treatment plants?

- Yes, steel I-beams can be used for wastewater treatment plants. Steel I-beams are commonly used in the construction industry due to their strength, durability, and versatility. In wastewater treatment plants, steel I-beams can be employed in structural components such as support beams, frames, and platforms. They provide the necessary strength and stability required to withstand heavy loads and harsh environmental conditions typically found in wastewater treatment facilities.

- Q: How are steel I-beams lifted into place during construction?

- Heavy-duty cranes are typically used to lift steel I-beams into place during construction. These cranes are specifically designed to handle the weight and size of the beams. To begin the process, the crane is positioned near the area where the beam needs to be installed. The beam is then securely attached to the crane using steel cables or chains. Once properly attached, the crane operator lifts the beam off the ground, taking into consideration its weight and balance. The operator controls the crane, maneuvering it into the correct position and then lowering the beam into place. To maintain the structural integrity of the building, it is crucial to ensure that the beam is aligned correctly with other structural components. Signalers or spotters on the ground may assist the crane operator in guiding the positioning of the beam. In some instances, multiple beams may need to be lifted and placed one after the other to form a complete structure. This requires careful coordination between the crane operator and the construction team to prioritize safety and efficiency. Once in its final position, the beam may be further secured using bolts or welds to connect it to other structural elements. These connections are essential for ensuring the overall stability and strength of the structure. Overall, the lifting of steel I-beams during construction demands skilled crane operators and a well-coordinated effort from the construction team. The use of cranes enables precise positioning of the beams, ensuring safe and accurate installation.

- Q: What is the purpose of steel I-beams?

- The purpose of steel I-beams is to provide structural support and strength in construction projects. I-beams are designed with a distinctive "I" shape, which allows them to efficiently distribute weight and withstand heavy loads. They are commonly used in the construction of buildings, bridges, and other structures where load-bearing capabilities are necessary. Steel I-beams offer several advantages, such as their high strength-to-weight ratio, durability, and versatility. Their design allows for a lighter and more cost-effective solution compared to other structural materials. Additionally, I-beams can be easily fabricated and customized to fit specific project requirements, making them a popular choice in the construction industry.

- Q: How do you mark the types of steel such as channel, I-beam and so on in the document?

- Section steel is a strip steel with definite section shape and size. It is one of the four big kinds of steel (plate, tube, mould, wire).

- Q: How do steel I-beams perform in terms of noise insulation?

- Steel I-beams typically do not provide significant noise insulation due to their rigid and dense nature. They are more commonly utilized for their load-bearing capabilities and structural strength rather than their ability to reduce noise transmission. To effectively reduce noise, additional insulation materials or alternative construction techniques should be considered.

- Q: Own attic, choose I-beam or channel?

- GB gb. Don't look cheap.There are many impurities in non GB steel, and the yield and tensile strength are not qualified. Does not meet the use requirements.

- Q: How do you determine the spacing and placement of steel I-beams in a structure?

- Determining the spacing and placement of steel I-beams in a structure is a complex process that requires careful analysis and consideration of multiple factors. These factors encompass the load-bearing requirements, beam span, type of structure, and adherence to building codes and regulations. To begin, the anticipated load that the beams will bear must be calculated. This involves assessing the permanent weight of the structure (dead loads), temporary weight such as furniture, people, and equipment (live loads), and any other specific loads imposed on the structure. By determining the load requirements, engineers can select the appropriate beam size and strength. After establishing the load requirements, the span of the beams needs to be determined. The span refers to the distance between the supports or columns where the beams will be placed. Longer spans necessitate stronger and larger beams to ensure structural integrity and prevent deflection or sagging. Once the load requirements and span are known, the structural engineer can consult building codes and regulations to ascertain the maximum allowable deflection and bending stress limits for the specific application. These codes provide guidelines for the maximum allowable spacing between beams and the minimum size or depth of the beams based on the loads and span. Beyond technical considerations, the type of structure also influences beam spacing and placement. In residential construction, beams are typically spaced at regular intervals along the length of the structure to support the floor and roof loads. However, in industrial or commercial buildings, the placement of beams may be influenced by the layout of the space, equipment, or specific architectural requirements. Engineers often utilize computer-aided design (CAD) software and structural analysis programs to optimize beam spacing and placement. These tools enable them to simulate various load scenarios and analyze the structural behavior of the beams. Through this process, adjustments and refinements can be made to ensure an efficient and safe design. In conclusion, determining the spacing and placement of steel I-beams in a structure requires a meticulous analysis of load requirements, span, building codes, and structural considerations. By carefully considering these factors, engineers can determine the ideal arrangement to achieve a strong, safe, and efficient structural design.

- Q: What are the considerations for steel I-beam design in high-wind speed areas?

- To ensure the structural integrity and safety of steel I-beams in high-wind speed areas, several factors must be taken into consideration: 1. Wind load calculation: Accurate calculation of the wind load is the first step. This involves considering the basic wind speed, the building's exposure category, and the importance factor of the structure. Wind tunnel testing and computer simulations may also be used for precise calculations. 2. Material selection: Choosing the right grade and quality of steel is crucial. High-strength steel is often preferred due to its superior tensile strength and ability to withstand higher wind loads. Corrosion-resistant steel should also be chosen to prevent deterioration over time. 3. Beam size and shape: The size and shape of the I-beam are determined by the wind load calculations. The beam must be designed to resist bending and shearing forces caused by the wind. Increasing the beam's depth and flange width can enhance its stiffness and resistance to bending. 4. Connection design: The connections between the I-beam and other structural elements must be carefully designed to withstand wind loads. Adequate moment and shear connections should be provided to transfer wind forces without compromising structural integrity. 5. Bracing and lateral support: Incorporating bracing and lateral support systems is essential to prevent excessive deflection or buckling of the I-beam. Diagonal braces, cross-bracing, or moment frames can provide stability and increase overall rigidity. 6. Anchorage and foundation design: The foundation system should be designed to resist uplift forces caused by the wind. Proper anchorage of the I-beam to the foundation is critical to prevent displacement during high winds. Anchors, such as anchor bolts or dowels, should be appropriately sized and positioned. 7. Building codes and regulations: Compliance with local building codes and regulations is essential. These codes specify minimum design requirements, construction techniques, and wind load factors that must be followed. Consulting with a structural engineer familiar with local codes is recommended. By considering these factors and following best practices, the design of steel I-beams in high-wind speed areas can be optimized for maximum safety and structural performance.

Send your message to us

Hot Rolled I-Beam Steel with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords