HR Steel Equal Beams with High Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

.

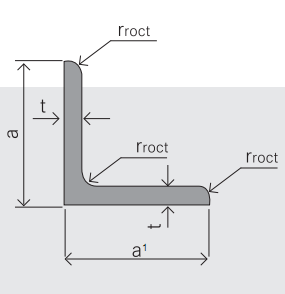

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery:

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:Can steel I-beams be used for sports stadiums?

- Yes, steel I-beams can be used for sports stadiums. In fact, they are commonly used due to their strength and durability, making them ideal for large-scale structures like stadiums.

- Q:What are the common testing methods used to verify the quality of steel I-beams?

- The common testing methods used to verify the quality of steel I-beams include visual inspection, dimensional analysis, mechanical testing such as tensile and yield strength tests, non-destructive testing methods like ultrasonic testing and magnetic particle inspection, and chemical composition analysis through spectroscopy.

- Q:What are the different connection methods for Steel I-Beams?

- Depending on the specific application and structural requirements, Steel I-Beams can be connected using several different methods. Some commonly used connection methods include: 1. Welding: The most frequently used method for connecting steel I-beams is welding. This involves melting the base metal and using a filler material to create a strong joint. Welding offers excellent strength and rigidity, making it suitable for heavy-duty applications. 2. Bolting: Steel I-beams can also be connected using bolts. This method involves drilling holes in the flanges or web of the I-beams and inserting bolts through these holes, along with washers and nuts, to secure the connection. Bolting provides ease of installation and disassembly, making it suitable for temporary or adjustable structures. 3. Riveting: Another traditional method for connecting steel I-beams is riveting. This process involves inserting rivets through pre-drilled holes in the flanges or web of the I-beams and deforming them to create a permanent connection. Riveting offers high strength and reliability but requires specialized tools and expertise. 4. Adhesive bonding: In certain cases, adhesive bonding can be used to connect steel I-beams. This method involves applying a high-strength adhesive to the surfaces of the I-beams and pressing them together to create a bond. Adhesive bonding can provide a clean and aesthetically pleasing connection, but it may not be suitable for heavy or dynamic loads. 5. Mechanical connectors: There are various mechanical connectors available in the market specifically designed for connecting steel I-beams. These connectors are often prefabricated and can be easily installed using bolts or welding. They offer a quick and efficient method of connecting I-beams while maintaining high strength and load-bearing capacity. When selecting the appropriate connection method for steel I-beams, it is important to consider the specific structural requirements, load conditions, and design constraints. Consulting with a structural engineer or a qualified professional is recommended to ensure that the chosen connection method meets the necessary standards and specifications.

- Q:Can steel I-beams be used in convention centers or exhibition halls?

- Yes, steel I-beams can be used in convention centers or exhibition halls. Steel I-beams are commonly used in construction due to their strength and load-bearing capabilities, making them suitable for large spaces like convention centers and exhibition halls that require structural support.

- Q:How about 5 tons of crane rail fixed on I-steel

- First, the pressure plate shall be punched on i-beam. Second the guide rail is screwed with a hook screw and third is welded directly with the welding pressure plate

- Q:What are the common safety considerations when working with steel I-beams?

- Some common safety considerations when working with steel I-beams include proper lifting techniques and equipment, ensuring the beams are securely fastened or braced to prevent movement or collapse, wearing appropriate personal protective equipment (PPE) such as hard hats and steel-toed boots, and adhering to proper weight limits and load distribution guidelines. It is also important to inspect the beams for any defects or damage before use and to follow established procedures for working at heights or in confined spaces.

- Q:What are the different types of connections used for steel I-beams?

- There are several different types of connections used for steel I-beams, depending on the specific application and structural requirements. Some common types of connections include: 1. Welded Connections: This is the most common and widely used type of connection for steel I-beams. It involves welding the I-beam to a connection plate or another beam to create a strong and durable joint. 2. Bolted Connections: Bolted connections are another common method used to connect steel I-beams. This involves using bolts and nuts to fasten the beams together. Bolted connections can be easily adjusted or dismantled if needed, making them a flexible option. 3. Riveted Connections: Riveted connections were historically used but are less common nowadays. This method involves using rivets, which are metal pins with a formed head on one end, to connect the I-beams. Riveted connections provide high strength and durability. 4. Pinned Connections: Pinned connections allow for rotational movement between the connected beams. This type of connection is often used in structures where flexibility is required, such as bridges or seismic-resistant buildings. Pinned connections typically use pins or bearings to allow rotation. 5. Moment Connections: Moment connections are designed to transfer both vertical and horizontal loads between beams. These connections are used in structures where a rigid connection is required to resist bending moments. Moment connections can be achieved through welding or bolting, and they provide high strength and stability. It's important to note that the choice of connection type depends on factors such as load requirements, structural design, and construction methods. Consulting with a structural engineer or a qualified professional is crucial to ensure the appropriate connection type is chosen for specific applications.

- Q:Can steel I-beams be used for high-temperature applications?

- No, steel I-beams are not typically recommended for high-temperature applications. While steel is known for its strength and durability, it can lose its structural integrity when exposed to high temperatures for extended periods. At elevated temperatures, steel can undergo thermal expansion, leading to distortion and potential failure. Additionally, prolonged exposure to high temperatures can cause steel to weaken, reducing its load-bearing capacity. For high-temperature applications, alternative materials such as refractory metals or ceramics that can withstand extreme heat conditions are often preferred.

- Q:How do you calculate the deflection of steel I-beams?

- To calculate the deflection of steel I-beams, you can use the Euler-Bernoulli beam theory or more advanced structural analysis methods such as finite element analysis (FEA). The Euler-Bernoulli beam theory involves applying the formula for deflection based on the applied load, beam properties (such as moment of inertia and modulus of elasticity), and the beam's length. FEA, on the other hand, utilizes computer simulations to determine the deflection by discretizing the beam into smaller elements and solving the structural equations numerically.

- Q:Can steel I-beams be used for religious buildings?

- Indeed, religious buildings can certainly make use of steel I-beams. Steel, being a versatile and durable material, offers numerous advantages in construction. Its strength, load-bearing capabilities, and resistance to fire and corrosion make it an ideal choice for supporting the structural framework of religious buildings, such as churches, temples, mosques, or synagogues. The steel I-beams provide the necessary structural integrity to bear the weight of the building, including the roof and any additional floors. They are capable of spanning long distances, allowing for open and spacious interior designs. This is particularly desirable in religious buildings, as it accommodates large gatherings and creates a sense of awe and reverence. Moreover, steel's fire-resistant properties add an extra level of safety, which is crucial in religious buildings where large crowds may gather. Its resistance to corrosion also ensures the longevity and durability of the structure, resulting in reduced maintenance costs over time. Furthermore, steel's versatility allows for innovative architectural designs that can reflect the cultural or spiritual aspects of a particular faith. Steel I-beams can be easily incorporated into both traditional and contemporary architectural styles, providing flexibility in design choices. In conclusion, due to their strength, durability, fire resistance, and versatility, steel I-beams are definitely suitable for religious buildings. They not only provide the necessary structural support but also allow for spacious and architecturally appealing designs that cater to the needs and aesthetic preferences of various faith communities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HR Steel Equal Beams with High Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords