Heavy Steel with High Quality for Structure Prefabricated House

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Heavy Steel with High Quality for Structure Prefabricated House:

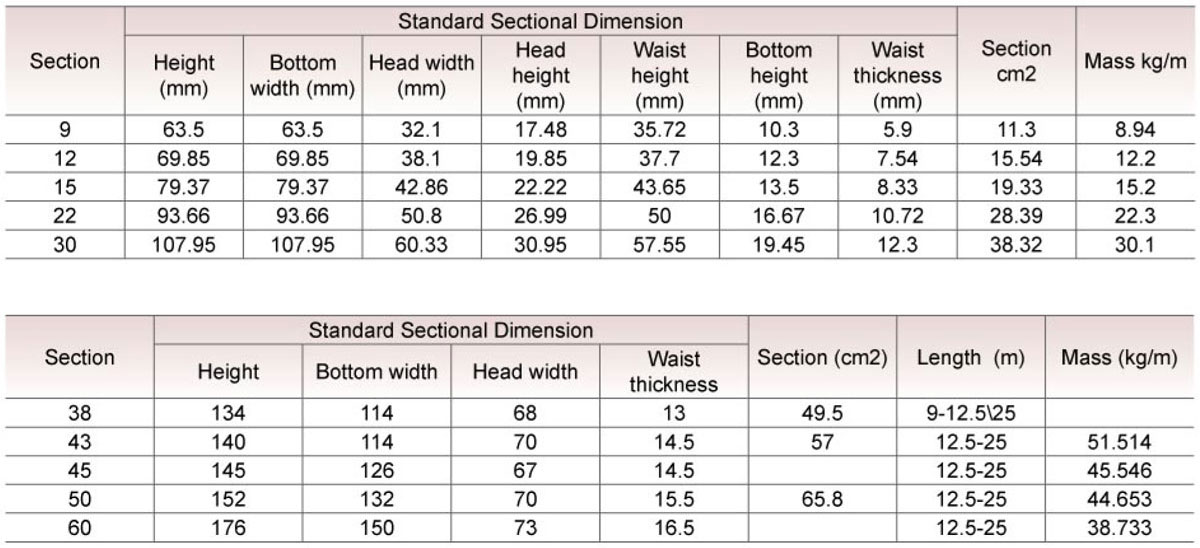

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Heavy Steel with High Quality for Structure Prefabricated House:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Heavy Steel with High Quality for Structure Prefabricated House:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Heavy Steel with High Quality for Structure Prefabricated House:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: What makes stainless steel stainless?

A1: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q3: Why buy Materials & Equipment from OKorder.com?

A3: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Images:

- Q: How are steel rails protected from landslides?

- Steel rails are protected from landslides through various measures to ensure the safety and stability of railway tracks. One common method is the construction of retaining walls along the track alignment. These walls are typically made of concrete or other sturdy materials and are designed to prevent soil or debris from sliding onto the rails. Another approach is the use of slope stabilization techniques, such as installing rock bolts or soil nails into unstable slopes. These measures help to reinforce the ground and prevent it from shifting or sliding during landslides. Additionally, the use of geotextiles, which are synthetic materials that promote soil stability, can be applied to reinforce the embankments and prevent erosion. Regular inspection and maintenance of the railway infrastructure are also crucial in preventing landslides. Monitoring systems, such as inclinometers and ground-penetrating radar, can be employed to detect any signs of slope movement in advance. This allows for timely mitigation measures to be taken, such as slope reinforcement or diversion of water flow to prevent saturation of the soil. Furthermore, proper drainage systems are essential to prevent excessive water accumulation, which can weaken the ground and trigger landslides. This includes the installation of culverts, ditches, and gutters to ensure the efficient flow of water away from the railway tracks. Overall, a combination of engineering techniques, regular maintenance, and effective monitoring systems is employed to protect steel rails from landslides. These measures aim to enhance the stability and resilience of the railway infrastructure, ensuring the safe and uninterrupted operation of trains.

- Q: Are steel rails susceptible to warping?

- Yes, steel rails can be susceptible to warping under certain conditions.

- Q: How do steel rails handle continuous welded rail joints?

- Efficiently handling continuous welded rail joints is the purpose of steel rails. Continuous welded rail (CWR) involves joining rail sections with a continuous weld, eliminating the need for individual rail joints. This type of rail joint offers several advantages compared to traditional bolted joints. Steel rails are constructed from high-quality steel engineered specifically to withstand the stresses and loads imposed upon them. They are designed to be extremely strong, durable, and resistant to wear and tear. This allows them to effectively manage continuous welded rail joints. Continuous welded rail joints provide a smooth and seamless surface for trains to travel on. By eliminating individual rail joints, the impact and vibration caused by passing trains are minimized. This reduces the risk of rail fractures and enhances the overall stability and safety of the rail infrastructure. Furthermore, the continuous weld in CWR joints creates a continuous electrical path along the rail track. This is crucial for the operation of signaling systems and other electrical equipment utilized in railway networks. The steel rails ensure that the electrical conductivity is maintained, facilitating efficient communication and control throughout the rail network. Steel rails are also designed to offer consistent and uniform support for train wheels. The continuous welded rail joints create a continuous running surface, promoting a smooth ride for trains. This reduces wear and tear on both the steel rails and train wheels, resulting in lower maintenance costs and longer service life. In conclusion, steel rails are well-suited to handle continuous welded rail joints. Their strength, durability, and ability to provide a smooth and stable running surface make them an ideal choice for modern rail infrastructure. The continuous welds in CWR joints enhance safety, electrical conductivity, and overall operational efficiency in railway networks.

- Q: Are steel rails suitable for high-speed train operations?

- Steel rails are indeed suitable for high-speed train operations. They have been utilized in railway systems worldwide for many years, including those specifically designed for high-speed trains. Steel is a robust and enduring material that is capable of withstanding the immense pressures and fast speeds of modern trains. Furthermore, steel rails possess exceptional track stability and are capable of enduring extreme weather conditions, thus rendering them suitable for high-speed train operations in various environments. Additionally, steel rails offer a smooth and dependable surface for trains to traverse, resulting in reduced vibrations and ensuring a comfortable journey for passengers. All in all, steel rails have demonstrated themselves to be a dependable and efficient choice for high-speed train operations.

- Q: How are steel rails protected from damage caused by wildlife?

- Steel rails are typically protected from damage caused by wildlife through the use of various measures such as fencing, wildlife deterrents, and regular inspections. Fencing helps to prevent animals from accessing the tracks, while wildlife deterrents like noise devices or visual deterrents are used to scare away animals. Additionally, regular inspections allow for the identification and removal of any potential hazards or obstacles that could cause damage to the steel rails.

- Q: How are steel rails protected against track buckling?

- Steel rails are protected against track buckling through a variety of measures. One common method is the use of continuous welded rail, where the rail segments are welded together to form a continuous track. This helps distribute the stress and prevent buckling. Additionally, rail anchors and fasteners are used to secure the rails to the sleepers, providing stability and preventing lateral movement. Proper maintenance, including regular inspections and temperature monitoring, is also crucial to identify potential issues and take preventive measures to avoid track buckling.

- Q: What are the main functions of nondestructive inspection of rail defects?

- Even endanger personal safety. Using nondestructive testing, RT, MT, PT and other conventional testing methods, it is easy to find defects that are difficult to observe by the naked eye. Prevent accidents and ensure quality.

- Q: What is the role of steel rails in train track circuit signaling?

- The role of steel rails in train track circuit signaling is crucial for the efficient and safe operation of trains. Steel rails serve as conductors in an electrical signaling system that helps control the movement of trains on a track. Track circuit signaling works by dividing the railway tracks into electrical sections or blocks, with each block having its own circuit. The steel rails act as the primary conductor for these circuits, completing the electrical circuit when a train passes over them. This allows for the detection of trains and facilitates automatic signaling and control of train movements. When a train passes over a section of track, the steel wheels and axles complete the electrical circuit between the two rails, creating an electrical presence that is detected by signaling equipment. This presence is then used to determine the train's location and speed, enabling the signaling system to communicate with the train and provide appropriate signals, such as speed restrictions or stop indications. The steel rails also play a critical role in maintaining the integrity of the electrical circuits. They need to be properly insulated from each other to prevent unintended electrical connections between adjacent circuits. Insulating materials, such as rubber pads or plastic clips, are used to isolate the rails and ensure the accuracy of the signaling system. Furthermore, the quality and condition of the steel rails are vital for reliable signaling. Any damage or wear on the rails can affect the conductivity of the circuits, leading to faulty signaling and potential safety hazards. Regular inspections and maintenance of the rails are necessary to ensure their proper functioning and to prevent disruptions in train operations. In summary, the role of steel rails in train track circuit signaling is to act as conductors, completing electrical circuits that detect the presence and movement of trains. They enable the signaling system to accurately monitor and control train movements, ensuring the safe and efficient operation of railways.

- Q: Are steel rails susceptible to wear and tear?

- Yes, steel rails are susceptible to wear and tear over time. Continuous use and exposure to factors like friction, weather conditions, and heavy loads can cause gradual deterioration of the steel rails, leading to wear and tear. Regular maintenance and inspection are necessary to ensure their optimal functioning and prevent any safety concerns.

- Q: What is the impact of steel rails on track alignment maintenance?

- The impact of steel rails on track alignment maintenance is profound. There are several ways in which steel rails play a crucial role in this regard. First and foremost, steel rails provide a solid and long-lasting foundation for the tracks. This enables them to withstand heavy loads and frequent train traffic without the need for frequent realignment and maintenance, unlike other rail materials. Furthermore, steel rails exhibit remarkable resistance to wear and tear. This quality ensures that the track alignment remains intact for an extended period. The constant friction and pressure exerted by the train wheels pose no threat to the steel rails, allowing the tracks to stay properly aligned and in excellent condition. Consequently, the frequency of track realignment and associated maintenance work is greatly reduced. Moreover, the use of steel rails allows for precise alignment during the installation process. These rails can be manufactured with utmost precision to meet stringent standards. As a result, the tracks are straight and uniform, leading to a more stable alignment. This precision alignment minimizes the occurrence of track irregularities, such as kinks or misalignments, which would otherwise necessitate increased maintenance efforts. Additionally, steel rails possess a high resistance to temperature changes. They expand and contract minimally in response to temperature fluctuations, mitigating the risk of track misalignment caused by thermal expansion or contraction. This unique property of steel rails ensures that the tracks remain properly aligned, reducing the need for frequent adjustments due to temperature-related issues. In conclusion, the impact of steel rails on track alignment maintenance cannot be overstated. The durability, resistance to wear and tear, precision alignment, and temperature resistance of steel rails all contribute to a more stable track alignment. As a result, the frequency of maintenance work required is significantly reduced, leading to improved efficiency and safety in train operations.

Send your message to us

Heavy Steel with High Quality for Structure Prefabricated House

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches