Light Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Light Rail

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

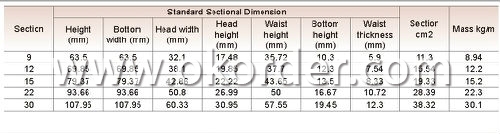

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| ||

Q235 |

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usages of Light Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Light Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Light Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: What is the role of steel rails in maintaining train stability?

- The role of steel rails in maintaining train stability is to provide a smooth and stable surface for the train wheels to roll on. The rails help distribute the weight of the train evenly, preventing it from tipping over or derailing. Additionally, the steel rails allow for precise and controlled movement of the train, ensuring safe and efficient travel.

- Q: What are the potential risks of using steel rails in corrosive environments?

- Several potential risks can arise when steel rails are used in corrosive environments. Firstly, exposure to certain elements like moisture, saltwater, and chemicals can cause corrosion in steel. In areas with high levels of industrial pollution or coastal regions, these elements can expedite the corrosion process, weakening the integrity of the rails and making them more susceptible to damage and failure. Secondly, corrosion can lead to the development of rust on the steel rails. Rust is a reddish-brown oxide that forms when iron reacts with oxygen and moisture. As rust accumulates on the rails, it can create surface irregularities, pitting, and roughness, resulting in a decline in rail performance. This can lead to issues like increased friction, noise, and vibration during train operations. In addition, as corrosion progresses, it can cause the steel rails to become thinner and weaker, potentially compromising their structural integrity. This increases the risk of rail buckling or breakage, which can be dangerous for both trains and passengers. In extreme cases, the corrosion can weaken the rails to the point where they can no longer support the weight of the trains, resulting in derailments and accidents. Another risk of using steel rails in corrosive environments is the higher costs associated with maintenance and replacement. Corrosion requires regular inspections, cleaning, and the application of protective coatings to prevent further damage. These maintenance activities can be both time-consuming and expensive. Moreover, the frequent replacement of corroded rails can lead to increased costs for rail operators and potential disruptions to train schedules. In conclusion, the use of steel rails in corrosive environments presents several potential risks, including accelerated corrosion, the formation of rust, decreased rail performance, compromised structural integrity, increased risk of accidents, and higher maintenance and replacement costs. Rail operators must prioritize the implementation of corrosion prevention and maintenance strategies to mitigate these risks and ensure the safe and efficient operation of rail systems in corrosive environments.

- Q: What are the properties of steel rails?

- Steel rails have several key properties that make them suitable for use in railway tracks. Firstly, steel rails are incredibly strong and durable, able to withstand heavy loads and resist deformation. They also have excellent wear resistance, as they are designed to endure the constant friction and impact from passing trains. Additionally, steel rails have high tensile strength, allowing them to stretch and flex under stress without breaking. This property is crucial for maintaining the structural integrity of the tracks. Moreover, steel rails are corrosion-resistant, ensuring a longer lifespan and reducing the need for frequent maintenance. Lastly, they have good thermal conductivity, enabling them to dissipate heat efficiently, which is crucial for preventing rail expansion and maintaining track stability.

- Q: What are the different rail profiles used in different countries?

- There are several rail profiles used in different countries, including the most common ones such as the "Vignoles" profile used in Europe, the "Bulb" profile used in North America, and the "Flat-bottomed" profile used in the United Kingdom. These profiles vary in dimensions and shape, but all serve the purpose of providing stability and smooth movement for trains.

- Q: How do steel rails contribute to the stability of a train?

- Steel rails contribute to the stability of a train by providing a secure and smooth track for the train to travel on. The rails are designed to withstand the weight and forces exerted by the train, ensuring that it remains on track and does not derail. The steel rails also help distribute the weight of the train evenly, allowing for better balance and stability during acceleration, deceleration, and turns.

- Q: What is the impact of track irregularities on steel rail performance?

- Track irregularities can have a significant impact on steel rail performance. These irregularities, such as misalignment, wear, and defects, can lead to increased noise, vibration, and rolling resistance, adversely affecting the stability and efficiency of trains. They can also accelerate rail wear and fatigue, resulting in higher maintenance costs and reduced rail lifespan. Additionally, track irregularities can compromise safety by increasing the risk of derailments and accidents. Therefore, it is crucial to regularly monitor and address track irregularities to ensure optimal steel rail performance and ensure the safety and efficiency of railway operations.

- Q: What are the main advantages of using steel rails?

- The main advantages of using steel rails are their durability, strength, and resistance to wear and tear. Steel rails can withstand heavy loads and provide a stable and smooth surface for trains to travel on. Additionally, steel rails have a longer lifespan compared to other materials, reducing maintenance and replacement costs.

- Q: How are steel rails protected against biological corrosion?

- Steel rails are protected against biological corrosion through various methods, including regular maintenance practices such as routine inspections, cleaning, and removing any vegetation or debris that may promote corrosion. Additionally, protective coatings, such as anti-corrosion paints or galvanization, are often applied to the steel rails to create a barrier against biological corrosion.

- Q: What are the common causes of rail buckling in steel rails?

- The common causes of rail buckling in steel rails can include excessive heat, expansion and contraction of the rails due to temperature changes, insufficient maintenance and inspection, improper alignment or fastening of the rails, and increased stress from heavy loads or high-speed trains.

- Q: How do steel rails contribute to the overall durability of train components?

- Steel rails contribute to the overall durability of train components by providing a strong and reliable track system. The steel rails are designed to withstand the heavy weight and constant movement of trains, ensuring stability and minimizing the wear and tear on other components such as wheels and axles. Additionally, the smooth surface of steel rails reduces friction, allowing for efficient and safe train operation, which further enhances the longevity of the overall train system.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Light Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords