Steel Pipe with High Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Steel Pipe Q345 Descrption:

Having vast industrial knowledge of domain, we are offering a quality approved array of Stainless Steel Round Pipe. The Stainless Steel Round Pipe we offer is widely demanded amongst the clients for its sturdiness and reliability. These products are tested for their quality before being introduced in the market.

2、Main Features of the Steel Pipe Q345:

·Highly demanded

·Durable

·Reliable

·resist corrosion

·reasonable price

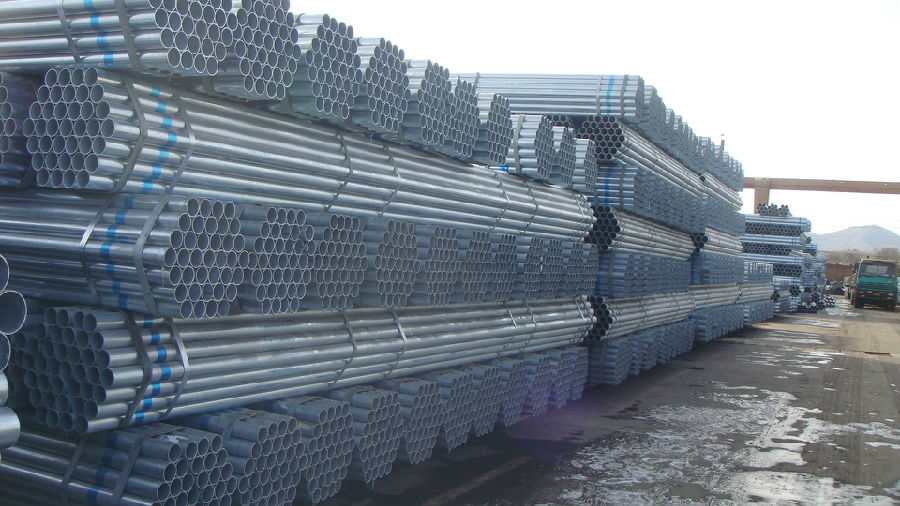

3、Steel Pipe Q345 Images:

4、The Steel Pipe Q345 Specification:

Standard JIS, DIN, ASTM

JIS G3445-2006, JIS G3444-2006, JIS G3446-2004, DIN EN 10216-1-2004, DIN EN 10217-1-2005, DIN EN 10305, ASTM A106-2006, ASTM A53-2007, ASTM A789-2001, ASTM A1020-2002, ASTM A179-1990, ASTM A199Grade Cr-Mo alloy, Mo, ST35-ST52, Q195-Q345, CrNi alloy

15CrMo, 10CrMo910, 30CrMo, 15Mo3, 16Mo, St37, St52, St42, St45, Q235, Q345, Q195, Q215, Cr17Ni8, 1Cr13Mn9Ni1NThickness 2 - 50 mm Section Shape Round Outer Diameter 10 - 900 mm Secondary Or Not Non-secondary Application Structure Pipe Technique EFW Certification API Surface Treatment Paint Special Pipe API Pipe Alloy Or Not Non-alloy

Specifications

1.W.T from 2mm to 70mm

2.OD from 10 to 1200mm

3.product by our own factory

4.on time dilivery

5、FAQ of Square Tube:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: Can steel pipes be used for steam distribution?

- Yes, steel pipes can be used for steam distribution. Steel pipes are commonly used in steam distribution systems due to their high strength, durability, and resistance to high temperatures and pressure. They can effectively handle the transportation of steam in various industries such as power generation, chemical processing, and heating systems.

- Q: How are steel pipes tested for strength and durability?

- Steel pipes are tested for strength and durability through various methods such as hydrostatic testing, non-destructive testing, and mechanical testing. Hydrostatic testing involves pressurizing the pipe with water to check for any leaks or weaknesses. Non-destructive testing techniques like ultrasonic or magnetic particle testing are used to detect any flaws or defects within the pipe. Mechanical testing involves subjecting the pipe to various loads and stresses to assess its performance and resistance to deformation. These tests ensure that steel pipes meet the required standards and are capable of withstanding the intended applications.

- Q: What are the different end finishes available for steel pipes?

- There are several different end finishes available for steel pipes, depending on the specific application and requirements. Some of the most common end finishes include: 1. Plain End: This is the simplest and most common type of end finish, where the pipe ends are cut square and left plain without any additional treatment or threading. 2. Beveled End: A beveled end is an angled cut made at the end of the pipe, usually at a 30-degree angle. This allows for better welding and ensures a smooth transition between pipes. 3. Threaded End: Threaded ends are commonly used for pipes that need to be connected with other components using threaded fittings. The ends of the pipe are cut with external threads, allowing for easy assembly and disassembly. 4. Coupling End: Similar to threaded ends, coupling ends have internal threads instead of external threads. This allows for the connection of pipes using couplings or connectors. 5. Grooved End: Grooved ends are commonly used for pipes in fire protection systems or other applications that require quick and easy installation. The ends of the pipe are grooved, and then a coupling is used to connect and secure the pipes. 6. Flanged End: Flanged ends have a flat, wide surface with holes for bolts. This type of end finish is used when the pipe needs to be connected to other components using flanges, such as in piping systems or equipment connections. Each of these end finishes serves a specific purpose and is chosen based on the requirements of the application. The end finish selected will depend on factors such as the type of connection needed, the pipe's intended use, and the specific industry standards and regulations that apply.

- Q: How are steel pipes used in the construction of chemical plants?

- Steel pipes are widely used in the construction of chemical plants due to their durability, corrosion resistance, and ability to handle high pressure and temperature. These pipes are primarily utilized for transporting various chemicals, gases, and liquids within the plant, ensuring a safe and efficient flow of materials throughout the facility. They are commonly employed in the installation of process pipelines, utility systems, and structural supports, playing a crucial role in the overall functionality and reliability of chemical plants.

- Q: What are the different types of steel pipe tees?

- There are three main types of steel pipe tees: equal tee, reducing tee, and barred tee.

- Q: How are steel pipes used in the renewable energy sector?

- Steel pipes are commonly used in the renewable energy sector for various purposes, primarily in the construction and installation of infrastructure for wind and solar energy projects. Steel pipes are used to support and anchor wind turbine towers, as well as to transport compressed air or hydraulic fluid for the operation of wind turbines. They are also utilized in the construction of solar panel frameworks, providing stability and durability. Additionally, steel pipes are used in geothermal energy projects for the extraction and transportation of hot water or steam from underground sources to power plants. Overall, steel pipes play a crucial role in enabling the efficient and reliable operation of renewable energy systems.

- Q: Are steel pipes suitable for underground cable protection?

- Yes, steel pipes are suitable for underground cable protection. Steel pipes provide excellent durability and strength, making them ideal for protecting cables from external factors such as physical damage, moisture, and corrosion. They are able to withstand the weight of the soil and any potential pressure from above, ensuring the cables remain secure and protected. Additionally, steel pipes can be easily welded or connected to create a continuous and seamless conduit, further enhancing their effectiveness in underground cable protection.

- Q: What are the different sizes available for steel pipes?

- Steel pipes are available in a wide range of sizes, ranging from small diameters as small as 1/8 inch to larger diameters exceeding 72 inches. The sizes of steel pipes are typically measured based on their outside diameter (OD) and wall thickness, with various standard sizes available to meet different application requirements.

- Q: Can steel pipes be used for paper mills?

- Yes, steel pipes can be used for paper mills. Steel pipes are commonly used in paper mills for various purposes such as transporting fluids, chemicals, and steam within the facility. They are known for their durability, strength, and resistance to corrosion, making them suitable for the harsh conditions and high-pressure requirements of paper mill operations.

- Q: What are the common grades of steel used in pipes?

- The common grades of steel used in pipes include ASTM A53, ASTM A106, and API 5L.

Send your message to us

Steel Pipe with High Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords