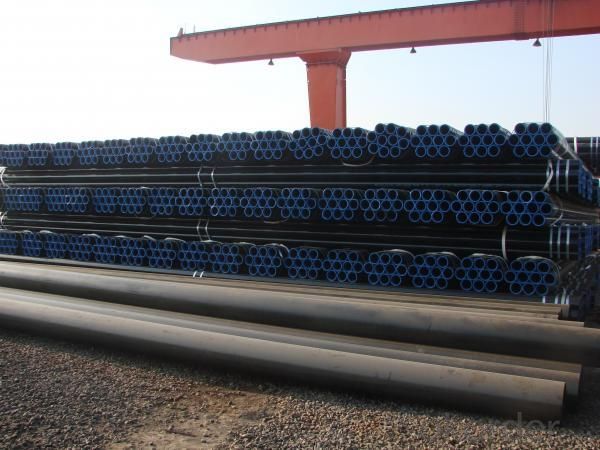

API 5L Line Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- Based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

API 5L Line Pipes

Application of API 5L Line Pipes:

It is widely applied to line pipe and casing and tubing in oil transportation and casing field, and it is used in Low,high pressure liquid and gassy transportation and it is also good Structure pipe (for furniture, window, door, building , bridge, mechanical etc).

Package of API 5L Line Pipes:

Bundles with anti-rust painting and with plastic caps

Standard of API 5L Line Pipes:

API SPEC 5L, API SPEC 5CT, ASTM A53, GB/T9711.1

Steel Grade of API 5L Line Pipes:

API SPEC 5L: B, X42, X46, X52, X56, X60, X65

API SPEC 5CT: J55, K55, N80, L80-1

ASTM A53: A, B, C

GB/T9711.1:L242、L290、L320、L360、L390、L415、L450

Sizes of pipes of API 5L Line Pipes:

*Remark: Besides below sizes, we also can arrange production based on requirement of customers

OD | WT | WEIGHT | ||||

INCH | MM | SCH | MM | INCH | KG/M | LB/INCH |

1 1/2” | 48.3 | STD-40 | 3.68 | 0.145 | 4.09 | 2.75 |

1 1/2” | 48.3 | XS-80 | 5.08 | 0.2 | 5.47 | 3.68 |

2” | 60.3 | STD-40 | 3.91 | 0.154 | 5.49 | 3.69 |

2” | 60.3 | XS-80 | 5.54 | 0.218 | 7.56 | 5.08 |

2 1/2” | 73 | STD-40 | 5.16 | 0.203 | 8.72 | 5.86 |

2 1/2” | 73 | XS-80 | 7.01 | 0.276 | 11.52 | 7.74 |

3” | 88.9 | STD-40 | 5.49 | 0.216 | 11.41 | 7.67 |

3” | 88.9 | XS-80 | 7.62 | 0.3 | 15.43 | 10.37 |

3 1/2” | 101.6 | STD-40 | 5.74 | 0.226 | 13.71 | 9.21 |

3 1/2” | 101.6 | XS-80 | 8.08 | 0.318 | 18.83 | 12.65 |

4” | 114.3 | STD-40 | 6.02 | 0.237 | 16.24 | 10.91 |

4” | 114.3 | XS-80 | 8.56 | 0.337 | 22.55 | 15.15 |

5” | 141.3 | STD-40 | 6.55 | 0.258 | 21.99 | 14.78 |

5” | 141.3 | XS-80 | 9.53 | 0.375 | 31.28 | 21.02 |

6” | 168.3 | STD-40 | 7.11 | 0.28 | 28.55 | 19.19 |

6” | 168.3 | XS-80 | 10.97 | 0.432 | 42.99 | 28.89 |

8” | 219.1 | STD-40 | 8.18 | 0.322 | 42.98 | 28.88 |

8” | 219.1 | XS-80 | 12.7 | 0.5 | 65.3 | 43.88 |

10” | 273 | STD-40 | 9.27 | 0.365 | 60.9 | 40.92 |

10” | 273 | 80 | 15.09 | 0.594 | 96.95 | 65.15 |

12” | 323.8 | STD | 9.53 | 0.375 | 74.61 | 50.13 |

12” | 323.8 | 40 | 10.31 | 0.406 | 80.51 | 54.1 |

12” | 323.8 | XS | 12.7 | 0.5 | 98.42 | 66.14 |

12” | 323.8 | 80 | 17.48 | 0.688 | 133.38 | 89.63 |

14” | 355.6 | 40 | 11.13 | 0.438 | 95.51 | 64.18 |

14” | 355.6 | XS | 12.7 | 0.5 | 108.48 | 72.9 |

14” | 355.6 | 80 | 19.05 | 0.75 | 159.71 | 107.32 |

16” | 406.4 | XS-40 | 12.7 | 0.5 | 124.55 | 83.69 |

18” | 457 | STD | 9.53 | 0.375 | 106.23 | 71.38 |

18” | 457 | 40 | 14.27 | 0.562 | 157.38 | 105.75 |

18” | 457 | 80 | 23.83 | 0.938 | 257.13 | 172.78 |

20” | 508 | 40 | 15.09 | 0.594 | 185.28 | 124.5 |

20” | 508 | 80 | 26.19 | 1.031 | 314.33 | 211.22 |

Raw Materials

- Q: What is the difference between black steel pipes and galvanized steel pipes?

- Black steel pipes and galvanized steel pipes differ in their coating. Black steel pipes are uncoated and have a dark, matte appearance, while galvanized steel pipes are coated with a layer of zinc to prevent corrosion. The galvanization process provides added protection and durability, making galvanized steel pipes suitable for outdoor or high-moisture environments.

- Q: What's the difference between a cracked carbon steel tube and a liquid carbon steel tube?

- Cracking carbon steel pipe higher requirements, the general carbon steel pipe to be normalized, the fluid carbon steel pipe as long as the normal annealing treatment.

- Q: Are steel pipes suitable for use in sewage treatment plants?

- Yes, steel pipes are suitable for use in sewage treatment plants. Steel pipes are durable, corrosion-resistant, and can withstand high-pressure applications, making them an ideal choice for transporting and containing sewage in treatment plants. Additionally, steel pipes can be easily welded, allowing for seamless connections and minimizing the risk of leaks or contamination.

- Q: How are steel pipes insulated for thermal purposes?

- Various methods are commonly employed to insulate steel pipes for thermal purposes. One method frequently utilized involves wrapping the pipes with insulation materials like fiberglass, mineral wool, or foam. These materials act as a barrier between the pipe and its surroundings, effectively preventing heat transfer or loss. To ensure the proper insulation of steel pipes, the insulation material is typically tightly wrapped around the pipe, leaving no gaps or openings for heat to escape. Adhesive tapes or metal bands are then used to secure the insulation in place. In addition to external insulation, internal insulation can also be applied to steel pipes. This involves placing insulation material inside the pipe, creating a protective layer against heat loss or gain. Internal insulation is commonly utilized in situations where the pipe carries hot fluids or gases. Moreover, certain steel pipes are designed to incorporate a built-in insulation layer. These pipes, known as pre-insulated pipes, already come equipped with insulation material integrated into their structure. The insulation layer is typically made of foam or mineral wool and is covered with a protective outer layer, ensuring effective thermal insulation. The insulation of steel pipes for thermal purposes plays a critical role in various industries, including oil and gas, HVAC, and plumbing. Proper insulation helps to maintain the desired temperature of fluids or gases flowing through the pipes, preventing energy loss and enhancing overall efficiency.

- Q: What kind of argon arc welding wire is used for 16Mn steel pipe?

- JB/T4709 recommends H10MnSi, but H10MnSi allows a lower value of strength of 430MPa, which does not match the parent material. I think American Standard is selected according to the selection of welding wire ER70S-6 GB ER50-6 wire can guarantee the equivalent strength of parent materials, and Si, Mn content can also guarantee the deoxidation effect, the weld joint is not easy to produce pores.

- Q: How are steel pipes used in the construction industry?

- Steel pipes are commonly used in the construction industry for various purposes such as transporting fluids, structural support, and underground installations. They are utilized in plumbing systems, HVAC systems, and for conveying water, oil, and gas. Additionally, steel pipes are employed in the construction of high-rise buildings, bridges, and other infrastructure projects due to their durability, strength, and resistance to corrosion.

- Q: What is the difference between steel pipe and polyethylene pipe?

- Steel pipe and polyethylene pipe are two different types of materials used for plumbing and construction purposes. The main difference between these two pipes lies in their composition and characteristics. Steel pipe is made from a combination of iron and carbon, which gives it its strength and durability. It is commonly used in applications where high pressure and heavy loads are expected, such as in industrial settings or for underground gas and oil pipelines. Steel pipe is known for its resistance to corrosion and its ability to withstand extreme temperatures. On the other hand, polyethylene pipe is a type of plastic pipe made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE). It is lightweight, flexible, and easy to install, making it a popular choice for residential plumbing and irrigation systems. Polyethylene pipe is resistant to chemicals, UV rays, and abrasive materials, making it suitable for both above-ground and underground installations. Another significant difference between steel pipe and polyethylene pipe is their cost. Steel pipe generally tends to be more expensive due to the raw materials and manufacturing processes involved. Polyethylene pipe, on the other hand, is relatively affordable and cost-effective, especially for smaller-scale projects. In terms of maintenance, steel pipe requires periodic inspections and maintenance to prevent corrosion and ensure its longevity. Polyethylene pipe, on the other hand, is virtually maintenance-free due to its resistance to corrosion and chemical degradation. In summary, the main difference between steel pipe and polyethylene pipe lies in their composition, strength, durability, cost, and maintenance requirements. The choice between these two pipes depends on the specific needs of the project, taking into consideration factors such as pressure, load, budget, and environmental conditions.

- Q: What is the role of steel pipes in the construction of bridges?

- Steel pipes play a vital role in the construction of bridges as they are used for various purposes such as providing structural support, carrying water or gas, and facilitating the transportation of electrical and communication cables. Their strength, durability, and ability to withstand heavy loads make them an essential component in bridge construction, ensuring the stability and longevity of the structure.

- Q: Can steel pipes be used for agricultural irrigation?

- Yes, steel pipes can be used for agricultural irrigation. They are a durable and long-lasting option that can withstand high pressures and extreme weather conditions. Steel pipes also provide excellent protection against corrosion and damage, making them suitable for various irrigation systems in agriculture.

- Q: Are galvanized steel tubes the same as degaussing steel tubes?

- Degaussing steel tubeThe degaussing method specifies the following demagnetization in the established process document

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2004 |

| Annual Output Value | 250,000Tons |

| Main Markets | Europe; South America; Americas;etc. |

| Company Certifications | API 5L;API 5CT;ISO 9001:2008 GB/T 19001-2008;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 1000-2000 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 70,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

API 5L Line Pipes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- Based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords