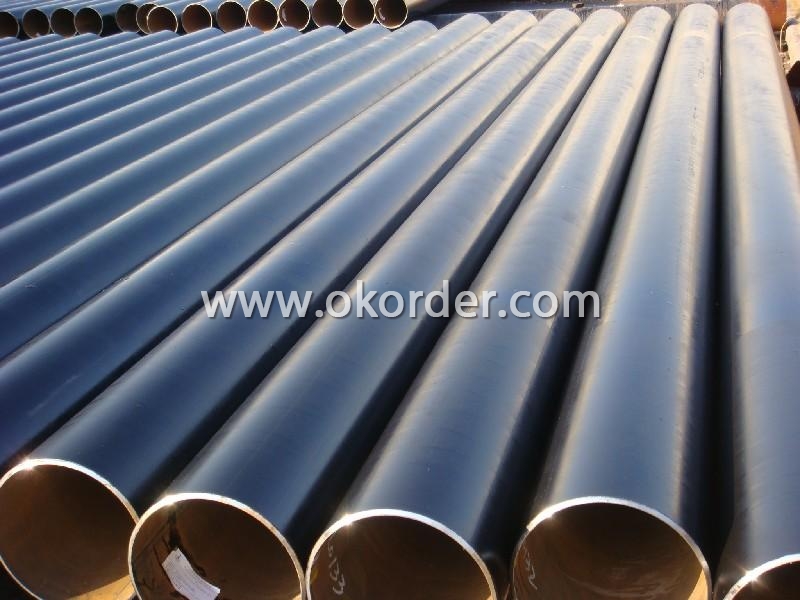

High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t. m.t.

- Supply Capability:

- Based On Order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries

Products Type Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

API 5L LSAW Welded Steel Pipes

Longitudinal Submerged Arc Welded (LSAW) Steel Pipe

API 5L SSAW Welded Steel Pipes

Spiral Submerged Arc Welded (SSAW) Steel Pipe

API 5L ERW Welded Steel Pipes

Electric Resistance Arc Welded (ERW) Steel Pipe

Specifications of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

Standard: API 5L, IPS, GB, BS, ASTM, JIS, ISO

Main Steel Tube Grade: A.B.X42,X46,X52,X56,X60,X70,L242、L290、L320、L360、L390、L415、L450(etc)

Dimensions:

OD: 406.4MM-1422MM (16"-56")

Thickness: 8MM-50.8MM depends on OD

Length: 5.8M-12M

Mechanical Properties Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

|

Standard |

Grade |

(MPa) |

(MPa) | |||

|

Yield strength |

Tensile Strength | |||||

|

API SPEC 5L |

PSL1 | |||||

|

B |

≥241 |

≥414 | ||||

|

×42 |

≥290 |

≥414 | ||||

|

×46 |

≥317 |

≥434 | ||||

|

×52 |

≥359 |

≥455 | ||||

|

×56 |

≥386 |

≥490 | ||||

|

×60 |

≥414 |

≥517 | ||||

|

×65 |

≥448 |

≥531 | ||||

|

×70 |

≥483 |

≥565 | ||||

|

PSL2 | ||||||

|

|

Min |

Max |

Min |

Max | ||

|

B |

241 |

448 |

441 |

758 | ||

|

×42 |

290 |

496 |

414 |

758 | ||

|

×46 |

317 |

524 |

434 |

758 | ||

|

×52 |

359 |

531 |

455 |

758 | ||

|

×56 |

386 |

544 |

490 |

758 | ||

|

×60 |

414 |

565 |

517 |

758 | ||

|

×65 |

448 |

600 |

531 |

758 | ||

|

×70 |

483 |

621 |

565 |

758 | ||

Chemical Composition Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries: (%)

|

Standard |

Grade |

C |

Mn |

P |

S |

CEV |

|

Max |

Max |

Max |

Max |

Max | ||

|

PSL1 |

- | |||||

|

B |

0.26 |

1.2 |

0.030 |

0.030 | ||

|

×42 |

0.26 |

1.3 |

0.030 |

0.030 | ||

|

×46,×52,×56,X60 |

0.26 |

1.4 |

0.030 |

0.030 | ||

|

X65 |

0.26 |

1.45 |

0.030 |

0.030 | ||

|

X70 |

0.26 |

1.65 |

0.030 |

0.030 | ||

|

PSL2 |

0.43 | |||||

|

B |

0.22 |

1.20 |

0.025 |

0.015 | ||

|

×42 |

0.22 |

1.30 |

0.025 |

0.015 | ||

|

×46,×52,×56, X60 |

0.22 |

1.40 |

0.025 |

0.015 | ||

|

X65 |

0.22 |

1.45 |

0.025 |

0.015 | ||

|

X70 |

0.22 |

1.65 |

0.025 |

0.015 | ||

Usage/Applications Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

It is widely applied to line pipe in oil and sewage transportation, and it is used in Low pressure liquid and gassy transportation and it is also good Structure pipe in building and bridge field.

It also can be used for conveying gas, water and petroleum for oil and natural gas industries

Packaging & Delivery Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

Packaging: with anti-rust painting and with plastic caps, or with PVC package, or hot dipped galvanized, or 3 PE coating

Delivery: by containers or by bulk vessel

- Q:How do steel pipes differ from other types of pipes?

- Steel pipes differ from other types of pipes in a few key ways. Firstly, steel pipes are known for their strength and durability. They have a high resistance to heat, pressure, and corrosion, making them suitable for a wide range of applications. This strength also allows steel pipes to withstand heavy loads and provide a long service life. Another distinguishing feature of steel pipes is their versatility. Steel pipes can be manufactured in various shapes and sizes to meet specific project requirements. This adaptability makes them a popular choice for a wide range of industries, including construction, oil and gas, water treatment, and manufacturing. Steel pipes also offer excellent thermal conductivity, meaning they can efficiently transfer heat from one area to another. This makes them suitable for applications such as heating and cooling systems, as well as for transporting hot fluids or gases. Furthermore, steel pipes are known for their resistance to fire. They have a high melting point and do not easily catch fire or contribute to the spread of flames. This property is crucial in applications where fire safety is a concern, such as in buildings or industrial facilities. Lastly, compared to other types of pipes, steel pipes have a higher initial cost. However, their long-term benefits, such as their durability and low maintenance requirements, often outweigh the initial investment. Steel pipes are also highly recyclable, making them an environmentally friendly choice. In summary, steel pipes stand out from other types of pipes due to their strength, durability, versatility, excellent thermal conductivity, fire resistance, and recyclability. These qualities make steel pipes a preferred option for a wide range of applications in various industries.

- Q:What is the primary purpose of steel pipes?

- The primary purpose of steel pipes is to transport fluids and gases, such as water, oil, and natural gas, over long distances efficiently and safely. They are commonly used in various industries including construction, oil and gas, and infrastructure development.

- Q:What is the fire rating of steel pipes?

- The fire rating of steel pipes can vary depending on factors such as the thickness of the pipe, the type of insulation or fireproofing materials used, and the specific application or building codes. However, steel pipes are generally considered to have good fire resistance properties due to their non-combustible nature and ability to withstand high temperatures.

- Q:What is the difference between hot-finished and cold-finished steel pipes?

- Hot-finished and cold-finished steel pipes are distinguished by their manufacturing processes, resulting in different characteristics and uses. Hot-finished steel pipes are manufactured by heating a solid steel billet to a high temperature and then piercing it to create a hollow tube. This process is known as hot rolling. The hot rolling process ensures that the steel is malleable and can be easily shaped into the desired form. Hot-finished steel pipes have a rough surface and more rounded edges. They are typically larger in diameter and have thicker walls. These pipes are commonly used in applications that require high strength and resistance to pressure, such as in the oil and gas industry, structural projects, and heavy machinery. In contrast, cold-finished steel pipes are made through a process called cold drawing. This involves pulling the hot-finished steel pipe through a die at room temperature to reduce its diameter and achieve the desired shape. The cold drawing process provides a more precise and smoother finish to the steel pipes. Cold-finished steel pipes have a smoother surface and sharper edges compared to hot-finished pipes. They are generally smaller in diameter and have thinner walls. Cold-finished steel pipes are commonly used in applications that require precise dimensions, such as automotive parts, construction components, and machinery manufacturing. Overall, the main difference between hot-finished and cold-finished steel pipes lies in their manufacturing processes, resulting in variations in surface finish, dimensions, and applications. Hot-finished pipes are suitable for high-strength and pressure-resistant applications, while cold-finished pipes are ideal for precise dimensions and smooth surface requirements.

- Q:What are the different types of steel pipe bends for pipeline routing?

- There are several different types of steel pipe bends commonly used for pipeline routing. These include 90-degree bends, 45-degree bends, and custom bends with specific angles as per the pipeline design requirements. Each type of bend serves a specific purpose in redirecting the flow of fluids or gases through the pipeline while maintaining structural integrity.

- Q:Can steel pipes be used for swimming pool installations?

- Yes, steel pipes can be used for swimming pool installations. Steel pipes are commonly used for plumbing systems and can be appropriate for swimming pool installations due to their durability and resistance to corrosion. However, it is important to ensure that the steel pipes are properly coated or treated to prevent rusting and deterioration in a pool environment. Additionally, other factors such as water pressure and compatibility with other pool equipment should also be considered.

- Q:Can steel pipes be used for offshore applications?

- Yes, steel pipes can be used for offshore applications. Steel pipes are commonly used in offshore oil and gas drilling operations, as they have high strength, durability, and resistance to corrosion, which are essential qualities for withstanding harsh marine environments. Additionally, steel pipes can be easily welded and fabricated to meet specific offshore project requirements.

- Q:What are the different types of steel pipe coatings?

- There are several types of steel pipe coatings, including epoxy coatings, polyethylene coatings, polyurethane coatings, and zinc coatings.

- Q:How are steel pipes protected from corrosion in corrosive environments?

- Steel pipes are protected from corrosion in corrosive environments through various methods such as coating the pipes with corrosion-resistant materials like epoxy or zinc, using cathodic protection techniques, and implementing regular inspections and maintenance to identify and address any potential corrosion issues.

- Q:Can steel pipes be used in the oil and gas industry?

- Indeed, the oil and gas industry commonly utilizes steel pipes. Renowned for their robustness, longevity, and resistance to corrosion, steel pipes are well-suited for the transportation and storage of diverse fluids and gases within this sector. They possess the ability to endure high pressure and extreme temperatures, which are frequently encountered during oil and gas operations. Moreover, the ease with which steel pipes can be welded together facilitates efficient assembly and maintenance. Consequently, steel pipes represent a dependable and economically sound option for the oil and gas industry.

1. Manufacturer Overview |

|

|---|---|

| Location | Wuxi, China |

| Year Established | 1980 |

| Annual Output Value | Above Three Million To Five Million RMB |

| Main Markets | Main land |

| Company Certifications | Certificate of Conformity; API 5CT |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-40% |

| No.of Employees in Trade Department | 1400 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 1500 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | CNPC;Sinopec Group |

| Product Price Range | Average |

Send your message to us

High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t. m.t.

- Supply Capability:

- Based On Order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords