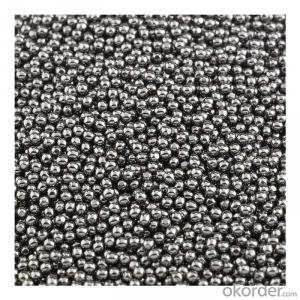

Chrome Steel Ball (G10) /52100 Balls/Bearing Ball/Steel Shot/Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Hot Rolled,Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

g10

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

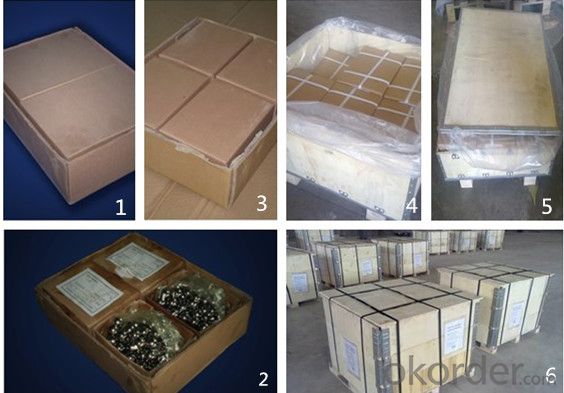

20kg/bag

Packaging:

Standard Export Packing

Our company is a professional AISI 52100 15.875mm-150mm G10-GG1000 chrome steel ball manufacturer for more than two decades. Before reformation, it is the joint venture with LYC.

Production procession

According to the ISO9001, we have established the strict & perfect quality assurance system, making sure that the whole production process is controlled and steady quality is offered to satisfy customers.

Composition of Different Materials

| Material | Chemical of Different Materals | ||||||||

| C | SI | Mn | P | S | Ni | Gr | Mo | Cu | |

| AISI440C | 0.95-1.20 | 1.00max | 1.00max | 0.040max | 0.030max | 0.60max | 16.00-18.00 | 0.75max | _ |

| AISI420C | 0.42-0.50 | 1.00max | 1.00max | 0.040ax | 0.030max | 1.00max | 12.5-14.5 | _ | 0.30max |

| AISI304 | 0.08max | 1.00max | 2.00max | 0.045max | 0.030max | 8.00-10.5 | 18.00-20.00 | _ | _ |

| AISI316 | 0.08max | 1.00max | 2.00max | 0.045max | 0.030max | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | _ |

| AISI E52100&GC r15 | 0.95-1.10 | 0.95-1.10 | 0.50max | 0.025max | 0.025max | _ | 1.30-1.60 | _ | _ |

Applications:

Chrome steel balls are applied in bearings such as slew bearing, deep groove ball bearing, thrust ball bearing, self aligning ball bearing, double-row bearing and etc.

Packing:

Carton box by wonden plates

our products are very well known in more than European and other foreign countries. your cooperation and order are warmly welcome!

- Q: What are the different types of steel storage racks?

- There are several different types of steel storage racks, including pallet racks, cantilever racks, drive-in racks, push-back racks, and flow racks. Each type is designed for specific storage needs and offers unique benefits and features.

- Q: What are the different types of steel stair treads and nosings?

- There are several types of steel stair treads and nosings available, including diamond plate treads, serrated treads, perforated treads, and abrasive nosings. Each type offers specific benefits such as slip resistance, durability, and ease of maintenance, catering to various safety and aesthetic requirements in different environments.

- Q: How does steel pipe threading work?

- Steel pipe threading is a process used to create threads on the ends of steel pipes. It typically involves using a die and a threading machine to cut the desired threads onto the pipe. The die is placed on the pipe and then the machine rotates the pipe while the die cuts the threads into the surface. This creates a threaded section on the pipe that can be used to connect it with other pipes or fittings. Threading is commonly used in various industries, including plumbing and construction, to ensure tight and secure connections between steel pipes.

- Q: How is steel used in the agricultural industry?

- Steel is used in the agricultural industry for various purposes such as constructing buildings, barns, and fences, manufacturing equipment like tractors and harvesters, and creating storage containers for crops and livestock.

- Q: What are the uses of steel in the manufacturing of household appliances?

- Steel is commonly used in the manufacturing of household appliances due to its durability, strength, and resistance to corrosion. It provides a sturdy framework for appliances such as refrigerators, ovens, and washing machines, ensuring their longevity and reliability. Additionally, steel's malleability allows for intricate designs and shapes, enabling manufacturers to create aesthetically pleasing appliances. Its ability to conduct heat efficiently also makes it suitable for applications such as cookware and heating elements.

- Q: How are steel gratings used in the construction of staircases and platforms?

- Steel gratings are commonly used in the construction of staircases and platforms to provide a sturdy and safe walking surface. They are often installed as treads on staircases, ensuring slip resistance and allowing for the drainage of water or other liquids. Additionally, steel gratings are also used as flooring on platforms, providing a durable surface that can withstand heavy loads and prevent accidents caused by slipping or tripping. Overall, steel gratings play a crucial role in enhancing the structural integrity and safety of staircases and platforms in construction projects.

- Q: How is steel used in the manufacturing of storage tanks?

- Steel is commonly used in the manufacturing of storage tanks due to its durability, strength, and resistance to corrosion. It provides a sturdy structure that can withstand high pressures and extreme weather conditions. Steel tanks can be fabricated in various sizes and shapes to accommodate different storage needs, making them versatile for storing various substances such as water, oil, chemicals, and gases.

- Q: How is steel used in the manufacturing of packaging materials?

- Steel is commonly used in the manufacturing of packaging materials due to its strength and durability. It is often used to create steel drums, cans, and containers that provide a secure and protective packaging solution for various goods. Steel packaging is widely used in industries such as food and beverage, chemicals, and pharmaceuticals, as it can withstand extreme temperatures, resist corrosion, and provide an airtight seal. Additionally, steel can be easily recycled, making it a sustainable choice for packaging materials.

- Q: What are the different types of steel bolts and their uses in the construction of power plants?

- There are several types of steel bolts used in the construction of power plants, each with their specific uses. Some common types include structural bolts, anchor bolts, and flange bolts. Structural bolts are typically used for heavy-duty applications and are designed to withstand high loads and provide structural stability. They are used in various areas of power plant construction, such as connecting steel beams, columns, and other structural elements. Anchor bolts are used to secure equipment and machinery to concrete foundations. They provide stability and prevent movement, especially in areas where vibrations or dynamic loads are present. These bolts are essential for securing large turbines, generators, and other equipment in power plants. Flange bolts are specifically designed for joining pipe flanges and other components in piping systems. They have a washer-like flange under the head, which distributes the load and helps prevent leaks. Flange bolts are crucial for maintaining the integrity of pipelines and ensuring the proper functioning of various power plant systems. The choice of steel bolts in power plant construction depends on factors such as the load requirements, environmental conditions, and specific applications. It is essential to select the appropriate type of bolt to ensure the safety, stability, and overall efficiency of power plant structures and systems.

- Q: What are the advantages of using steel bars in construction?

- There are several advantages of using steel bars in construction. Firstly, steel bars are incredibly strong and durable, providing structural integrity to buildings and ensuring they can withstand heavy loads and adverse weather conditions. Additionally, steel bars have a high tensile strength, allowing for longer spans and lighter structures, which can lead to cost savings in terms of materials and construction time. Moreover, steel bars are resistant to fire, corrosion, and pests, making them a reliable choice for long-term durability. Lastly, steel bars can be easily fabricated and customized to meet specific design requirements, offering flexibility and versatility in construction projects.

Send your message to us

Chrome Steel Ball (G10) /52100 Balls/Bearing Ball/Steel Shot/Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords