Best Price For Aluzinc Steel EN 10125

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 50000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

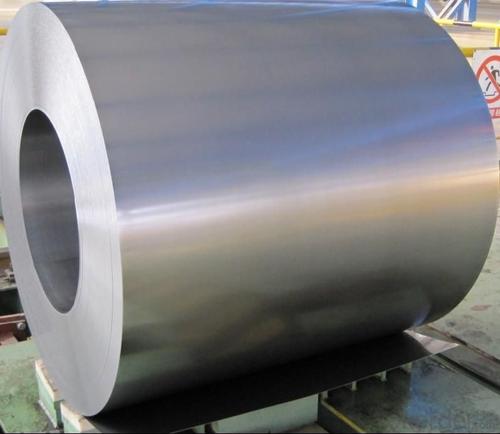

General Information Of Aluzinc Steel EN 10125

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

|

Thickness 0.25-4.0mm (BMT) |

|

Aluzinc Coating 50-150g/m2 |

|

Width 900-1250mm |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Surface Treatment Oiled or Dry, Chromated, Anti-finger,Non-skinpass,/ Skinpass |

|

Standard JIS G 3321, ASTM A792M, EN 10215 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel EN 10125

|

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

Technical Data Of Aluzinc Steel EN 10125

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out- of-Square |

Not exceed 1% Flatness |

|

Bow |

15mm max |

|

Edge Wave |

9mm max |

|

Centre Buckle |

8mm max |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Aluzinc Steel EN 10125

Aluzinc Steel can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliances.

Packaging & Delivery Of Aluzinc Steel EN 10125

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled with iron strips.

- Q: What are the different types of steel products used in the manufacturing of electronics?

- Some of the different types of steel products used in the manufacturing of electronics include stainless steel, carbon steel, and electrical steel. Stainless steel is commonly used for components that require corrosion resistance, such as enclosures and connectors. Carbon steel is used for structural components and fasteners due to its strength and affordability. Electrical steel, also known as silicon steel, is used for laminations in transformers and motors due to its magnetic properties.

- Q: How do steel products contribute to sustainable development?

- Steel products contribute to sustainable development in several ways. Firstly, steel is a highly recyclable material, which reduces the need for mining and extraction of new raw materials. This helps conserve natural resources and reduces the environmental impact of steel production. Additionally, steel has excellent durability and strength, leading to long product lifecycles and reducing the frequency of replacements. This not only saves resources but also reduces waste generation. Furthermore, steel is widely used in construction and infrastructure projects, contributing to the development of sustainable and resilient cities. Its ability to withstand extreme weather conditions and seismic events makes it an ideal choice for building structures that are durable, safe, and energy-efficient. Overall, steel products play a crucial role in promoting sustainable development by conserving resources, reducing waste, and creating resilient infrastructure.

- Q: What are the uses of steel in the oil and gas industry?

- Steel is widely used in the oil and gas industry for various applications due to its strength, durability, and resistance to corrosion. It is commonly used in the construction of oil rigs, pipelines, and storage tanks. Steel is also used in the manufacturing of valves, fittings, and other equipment necessary for the extraction, refining, and transportation of oil and gas. Its exceptional properties make steel a reliable and essential material in ensuring the safety and efficiency of operations in the oil and gas industry.

- Q: How is steel sheet metal fabricated?

- Steel sheet metal is fabricated through a process called sheet metal fabrication, which involves a series of steps such as cutting, bending, and shaping steel sheets to create the desired product or component. This can be done using various techniques, including laser cutting, shearing, punching, and forming, to achieve the desired shape and dimensions. Welding, riveting, or fastening methods are then used to join the different pieces together, resulting in a finished steel sheet metal product.

- Q: What are the applications of steel forgings in aerospace?

- Steel forgings have a wide range of applications in the aerospace industry. They are commonly used for critical components that require high strength, durability, and resistance to extreme temperatures. Some applications include aircraft engine components, landing gear, structural components, and wing attachments. Steel forgings offer superior mechanical properties and reliability, ensuring the safety and performance of aerospace systems.

- Q: What are the different types of steel products used in the telecommunications industry?

- Some of the different types of steel products used in the telecommunications industry include steel pipes, steel towers, steel cables, and steel brackets. These products are crucial in providing structural support, transmitting signals, and ensuring the reliability and durability of telecommunications networks.

- Q: What are the different types of steel wire ropes and their uses in mining operations?

- There are various types of steel wire ropes used in mining operations, including galvanized steel wire ropes, stainless steel wire ropes, and compacted steel wire ropes. Galvanized steel wire ropes are commonly used for general purpose applications due to their corrosion resistance. Stainless steel wire ropes are preferred in environments with high humidity and corrosive elements. Compacted steel wire ropes, on the other hand, are known for their increased strength and durability, making them suitable for heavy-duty mining operations. These wire ropes are primarily used for lifting, hauling, and supporting heavy loads in mining activities.

- Q: How are steel beams used in building structures?

- Steel beams are used in building structures as load-bearing elements that provide strength and stability. They are commonly used in the construction industry due to their high strength-to-weight ratio, allowing for the creation of large, open spaces without the need for excessive columns or supports. Steel beams distribute weight evenly, helping to support the weight of floors, walls, and roofs, and can withstand significant forces, such as wind and earthquakes. They are essential in constructing high-rise buildings, bridges, and industrial structures, where durability and structural integrity are paramount.

- Q: How is steel used in the construction of high-rise buildings?

- Steel is commonly used in the construction of high-rise buildings due to its strength, durability, and flexibility. It is used as the primary structural material, providing a sturdy framework that can withstand the weight and forces exerted on tall buildings. Steel beams and columns are used to support the floors, walls, and roof, allowing for open and spacious interior designs. Additionally, steel is utilized in the construction of elevator shafts, stairwells, and other critical components of high-rise buildings, ensuring their stability and safety.

- Q: What are the different types of steel bolts and their uses in automotive assembly?

- There are several types of steel bolts used in automotive assembly, including hex bolts, flange bolts, and carriage bolts. Hex bolts are the most common and are used to hold parts together securely. Flange bolts have a wide flange that distributes the load, making them suitable for applications with high vibration. Carriage bolts have a smooth, rounded head and a square neck, which prevents the bolt from turning when tightened. They are commonly used in automotive assembly for applications where a smooth appearance is desired.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Price For Aluzinc Steel EN 10125

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 50000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords