Piscinas En Geomembrana

Piscinas En Geomembrana Related Searches

Piscinas De Geomembrana Geomembrana Para Piscinas Tinas De Geomembrana Pozos De Geomembrana Geomembrana Para Piscicultura Geomembrana En Guatemala Tanques De Agua De Geomembrana Geomembrana Para Cisternas Instalación De Geomembrana Tanques De Geomembrana Bolsas De Geomembrana Instalacion De Geomembrana Geomembrana Para Reservorios Cisterna De Geomembrana Reservorio Con Geomembrana Ollas De Agua Con Geomembrana Geomembrana Para Ollas De Agua Reservorio De Geomembrana Geomembrana De Polietileno Geomembranes Geomembrana Para Techos Tanque De Geomembrana Geomembrana Para Impermeabilizar Tanques Para Peces Geomembrana Venta De Geomembrana Geomembrana En Ingles Geomembrana De Alta Densidad Termofusion De Geomembrana Geomembrana En Honduras Estanques De GeomembranaPiscinas En Geomembrana Supplier & Manufacturer from China

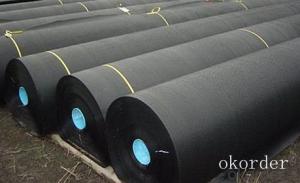

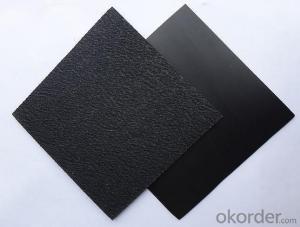

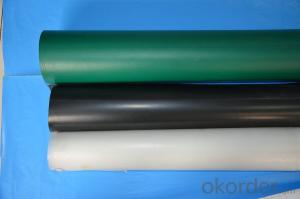

Piscinas En Geomembrana are specialized products designed for constructing swimming pools with high-quality geomembranes. These geomembranes are engineered to provide excellent water retention and resistance against various environmental factors, making them ideal for a range of applications in the swimming pool industry. The usage of Piscinas En Geomembrana is widespread, as they are suitable for both residential and commercial swimming pools, as well as for water storage and treatment facilities. Their versatility and durability have made them a popular choice among pool builders and engineers. Okorder.com is a leading wholesale supplier of Piscinas En Geomembrana, offering a vast inventory of these high-performance geomembranes to meet the demands of various projects. With their extensive selection and commitment to quality, Okorder.com has become a trusted source for Piscinas En Geomembrana and related products in the global market.Hot Products