Geocell for Road Construstion and Wall Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

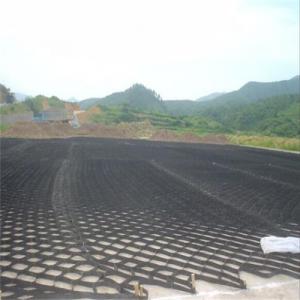

Geocell Description

Geocell is high-molecular polymer, connected by rivets or ultrasonic welded to three-dimensional network structure, unfold it and fill in sand, gravel and clay, etc. when used at construction site.

According to customer’s requirement, cut holes or carve arabesquitic in order to increase its lateral permeable ability, also increase the friction and binding force with the foundation material.

Geocell Specification

Welding distance:330-1000mm

Height:50-250mm

Surface: Textured or Smooth

Color: black,brown,green

Geocell Application

1) Used for the stability of railway road.

2) To stabilize the desert highway road.

3) Used in the governance of shallow water channel.

4) Used for the foundation reinforcement of retaining wall, wharf, levee.

5) For the management of desert, beaches and river banks

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: Does seepage-proof membrane belong to geomembrane?

- Geomembranes are widely used for their excellent seepage-proof performance measured by order of magnitude of 1*10*-13. The basic function of which is cultivation. The seepage-proof performance is good, but you'd better choose environmental ones with GBT17642-1998, GBT17643-2008 as well as other specifications and standards as reference.

- Q: What are the considerations for geomembrane installations in seismic zones?

- When installing geomembranes in seismic zones, several considerations need to be taken into account. Firstly, the geomembrane material should have adequate tensile strength and flexibility to withstand the ground movement caused by earthquakes. It is essential to choose a geomembrane that can elongate and deform without rupturing or tearing under seismic activity. Additionally, the anchorage and attachment of the geomembrane to the underlying subgrade should be carefully designed. Proper anchoring techniques, such as using tensioning devices or anchor trenches, must be employed to prevent the geomembrane from shifting or uplifting during seismic events. The geomembrane should also be securely fastened to any adjacent structures or containment systems to avoid potential damage or leakage. Furthermore, the design of the subgrade beneath the geomembrane should consider the seismic forces and soil liquefaction potential. Adequate soil compaction, reinforcement, and drainage measures should be implemented to ensure stability and prevent soil liquefaction, which can lead to ground failure and damage to the geomembrane. Regular inspections, maintenance, and repairs should be conducted to identify any potential damage or degradation of the geomembrane caused by seismic events. Early detection and timely repair can help prevent further deterioration and maintain the integrity of the geomembrane system in seismic zones.

- Q: What are the potential drawbacks of using geomembranes?

- One potential drawback of using geomembranes is their susceptibility to punctures or tears, which can compromise their effectiveness as a barrier. Additionally, geomembranes may degrade over time due to exposure to UV radiation or chemical reactions, reducing their lifespan. Installation and maintenance costs can also be significant, especially for large-scale projects. Lastly, improper installation or poor quality materials can lead to leakage or failure, causing environmental or safety hazards.

- Q: What are the functions of rubber diaphragm?

- Rubber diaphragm (NR) is hydrocarbon rubber (polyisoprene)-based, containing a small amount of protein, water, resin acids, sugars and inorganic salts. It features flexibility, high elongation strength, tear resistance and excellent electrical insulation, excellent wear resistance and drought tolerance, good workability, easy adhesion of other materials, and it is better than most synthetic rubber in terms of overall performance. The disadvantage is its poor resistance to oxygen and ozone, inclination to aging and deterioration; poor resistance to oil and solvent, low ability to resist corrosion to acid-base, and poor heat resistance. Operating temperature range: About -60 ℃ ~ + 80 ℃. It can be used to produce tires, rubber shoes, hose, tape, insulating layers of wire and cable and jacketing, and other common products. It is particularly suitable for producing torsional vibration eliminator, engine damper, the machine bearing, rubber - metal suspension components, diaphragms, and molded products.

- Q: How good of the quality of waterproof electrothermal?film?

- Waterproof electrothermal?film is the only surface heating product that can be implanted in the concrete.

- Q: What are the advantages of eletromembrane floor heating?

- 1, green and environmental protection, no environmental pollution electrothermal film heating system will not produce soot and dust, which is more in line with the requirements of urban planning, very suitable for the requirements of going green and environmental protection in modern society. 2, warm like the natural sunlight due to the electrothermal?film heating system use radiation mode to supply heating, it can bring people warm and comfortable feeling like bathing in the sunlight. Which will not produce dry and hot feeling like that produced by traditional heating system. 3, low temperature operation, safe and reliable The electrothermal film surface will keep running in low temperature during work and the highest temperature will not exceed 60 degrees Celsius, so scald, explosion and fire will not happen. The whole system is connected through parallel mode, running very stable and with high feasibility. 4, can be charged according to households As electrothermal?film heating system can sdapy to the needs of a variety of users, so it can be measured according to households, units or floors, etc., which enable users to control the electricity consumption freely.

- Q: What is the difference between nonwovens and geomembranes in hydraulic engineering?

- Non-woven and geomembrane, geosynthetics are two kinds of materials. From the appearance of: non-woven is a porous material permeable material. Geomembrane is generally dense and dense material. From their function to distinguish: non-woven mainly used to filter, isolation, high strength can also be used to strengthen, but with less, because the economy is irrational. Geomembrane, impermeable waterproof is its main function.

- Q: 500 grams thickness of 0.3 mm geomembrane a square meter two cloth a film how much money

- 500 grams thickness of 0.3 mm geomembrane a square meter two cloth a film price of 4 yuan. GB price will be more expensive.

- Q: Can geomembranes be used in agricultural applications?

- Yes, geomembranes can be used in agricultural applications. They are commonly used as liners for irrigation ponds, storage tanks, and canals to prevent water seepage and improve water management. They can also be used as covers for manure storage facilities to control odors and reduce contamination. Additionally, geomembranes can be utilized to line agricultural waste containment areas, helping to protect the environment by preventing the leaching of harmful substances into the soil and groundwater.

- Q: Which is better for geomembrane hot melting in the middle of sliding layer of high-speed railway bridge two cloth and one membrane, lapping or docking? And what is the lapping length if it is lapping hot melting?

- In general, it should not be cut according to graphic size. Shorten joint length and strain as far as possible. After geomembrane pavement, the lap?width between films should be not less than 10 cm. 4. Usually set at a corner and abnormal section. 6, arrange along the gradient direction and avoid accidental damage to membrane when the temperature is low. Lap width between membranes is generally not less than 10 cm. You should measure the accurate relative size. Do not weld as far as possible during geomembrane pavement . In addition to the special requirements, Do not walk on the membrane or carry on the membrane.

Send your message to us

Geocell for Road Construstion and Wall Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords