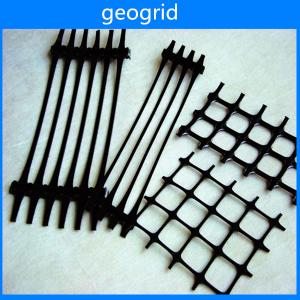

Geogrid For Soil Stabilization

Geogrid For Soil Stabilization Related Searches

Geogrid For Road Stabilization Geogrid Stabilization Geogrid Ground Stabilisation Geogrid For Erosion Control Geogrid Slope Stabilization Geogrid For Road Construction Geogrid Subgrade Stabilization Base Stabilization Geogrid Geogrid For Roads Geogrid For Slopes Geogrid For Steep Slopes Geogrid For Gravel Roads Geogrid For Gravel Geogrid For Driveways Geogrid For Retaining Wall Geogrid Applications Geogrid Reinforced Soil Laying Geogrid Geogrid Uses Geogrid For Pavers Geogrid Construction Geogrid For Driveway Geogrid For Horse Paddocks Geogrid Strength Geogrid Installation Geogrid For Gravel Driveway Purpose Of Geogrid Geogrid Stiffness Geogrid On Slope Retaining Wall GeogridGeogrid For Soil Stabilization Supplier & Manufacturer from China

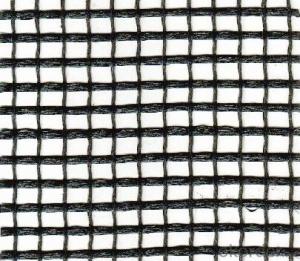

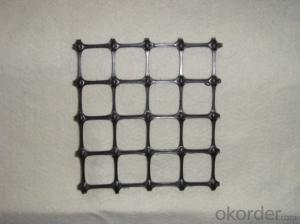

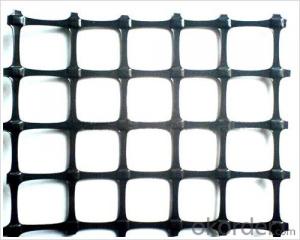

Geogrid for soil stabilization is a versatile and effective product used to reinforce soil and improve its load-bearing capacity. It is made from high-quality materials and engineered to provide optimal performance in various civil engineering projects. This product is designed to enhance the stability of soil structures, making it an essential component in the construction of roads, embankments, and retaining walls.The application and usage scenarios of geogrid for soil stabilization are extensive, as it can be utilized in a wide range of projects to improve soil integrity and reduce the risk of subsidence. This product is particularly useful in situations where the soil is weak or unstable, such as in areas with high water content or poor drainage. By incorporating geogrid into the soil, engineers can create a more robust and stable foundation, ensuring the longevity and safety of the constructed infrastructure.

Okorder.com is a leading wholesale supplier of geogrid for soil stabilization, offering a large inventory of this essential product. As a reputable supplier, Okorder.com is committed to providing high-quality materials at competitive prices, ensuring that customers can access the geogrid they need for their projects without breaking the bank. With a diverse range of geogrid options available, Okorder.com is the go-to destination for professionals in the construction and civil engineering industries who require reliable and durable soil stabilization solutions.

Hot Products