High Strength Plastic Geogrids for Soil Stabilization in India

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

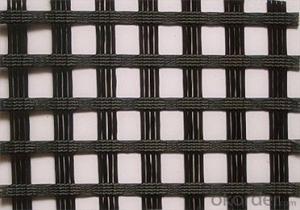

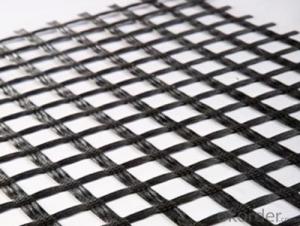

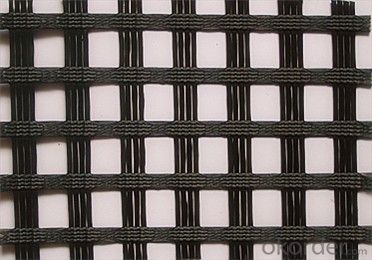

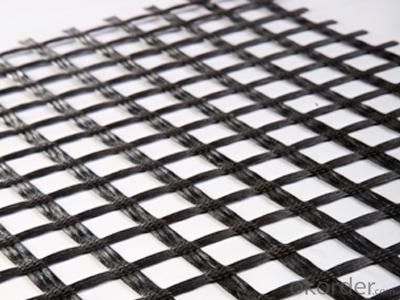

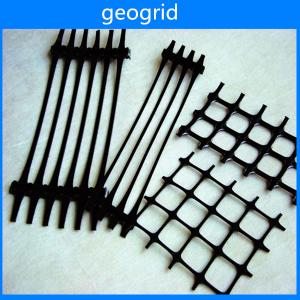

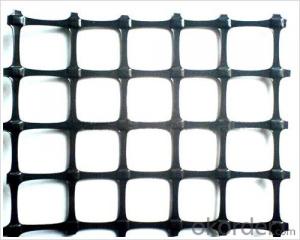

Structure of High Strength Plastic Geogrid:

High Tensile Strength Polyester Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of High Strength Plastic Geogrid:

fiberglass geogrid for soil reinforcement

Roadbed reinforcement of road and railway,crack prevention,increase of roadbed strength

fiberglass geogrid

Working & load transfer platforms

High tensile strength, low elongation

High stability

Reinforcement and stabilization of riverside,embankment and side slope;

High Strength Plastic Geogrid Images

High Strength Plastic Geogrid Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in temporary erosion control applications?

- Yes, geogrids can be used in temporary erosion control applications. They are often used to stabilize and reinforce soil in areas prone to erosion, such as construction sites or temporary access roads. Geogrids provide strength and stability to the soil, preventing erosion and promoting vegetation growth.

- Q: We would like to change the geogrid reinforced geogrid, I do not know what the reason for change is more reasonable

- Because the height of the geocell is very obvious, and the welding torch is very long, and the geogrid is very different

- Q: Geogrid and geotextile, the role is the same?

- Geogrid and geotextile are different

- Q: What are the differences between geogrids and geopipes?

- Geogrids and geopipes are both geosynthetic materials used in civil engineering and construction projects, but they serve different purposes. Geogrids are typically made of high-strength polymers or metals and are used to reinforce soil, providing stability and enhancing load-bearing capacity. They are commonly used in applications such as retaining walls, slope stabilization, and road and pavement construction. Geogrids have an open structure with interlocking apertures, allowing soil particles to interlock with the material, creating a strong composite. On the other hand, geopipes are typically made of high-density polyethylene (HDPE) and are used for subsurface drainage and water management systems. They have a perforated or slotted design that allows for the efficient collection and transportation of excess water from the soil. Geopipes are commonly used in applications such as underdrains, French drains, and stormwater management systems. In summary, geogrids are used for soil reinforcement and stability, while geopipes are used for subsurface drainage and water management.

- Q: What kind of products are the high strength and high strength micro - pile geocell? Introduce some specific details. Thank you

- The double direction high strength micro pile lattice chamber has a unique welding point strengthening edge structure. The high strength is achieved by strengthening the sheet between the edges.

- Q: How do geogrids enhance the stability of railway track cuttings?

- Geogrids enhance the stability of railway track cuttings by providing reinforcement to the soil. They are placed within the soil layers of the cutting and act as a strong and flexible support system. Geogrids distribute the load more evenly, reducing the stress on the soil and preventing its movement. This helps to prevent slope failures, soil erosion, and overall instability, ensuring the long-term stability and safety of the railway track cuttings.

- Q: How do geogrids improve the performance of reinforced soil slopes in expansive soils?

- Geogrids improve the performance of reinforced soil slopes in expansive soils by providing additional strength and stability to the soil. They help distribute the loads more evenly, reducing the risk of soil movement and slope failure. Geogrids also help mitigate the effects of soil expansion and contraction, as they create a barrier that limits the movement of soil particles. This enhances the overall structural integrity of the reinforced soil slope, making it more resistant to the damaging effects of expansive soils.

- Q: High density polyethylene one-way geogrid, tensile yield of 20kn/m

- Material is high density polyethylene material

- Q: How to determine the number of geogrid detection method

- In the finished product cut at least 1 meters of the length of the geogrid, the radial shear of the 3, the zonal shear of the 3, and then tested, take its average value can be.

- Q: How is a geogrid different from other geosynthetics?

- A geogrid is a type of geosynthetic that differs from other geosynthetics in its primary function and structural design. Unlike geotextiles or geocomposites that are primarily used for separation, filtration, or drainage purposes, geogrids are specifically designed to provide reinforcement and stabilization to soil and other materials. Geogrids are typically made of high-strength polymers and have a grid-like structure with open apertures, allowing them to interlock with soil particles and distribute loads more effectively. This unique design enables geogrids to enhance the mechanical properties of soils, increase their bearing capacity, and improve overall stability in various civil engineering applications.

Send your message to us

High Strength Plastic Geogrids for Soil Stabilization in India

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords