Geo Cells and Geogrids - Bitumen Coated Fiberglass Geogrid with Certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

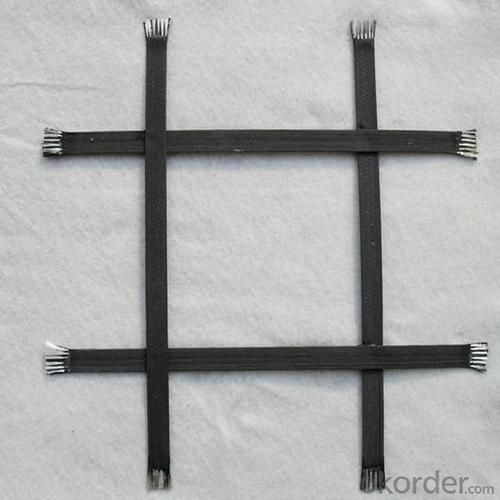

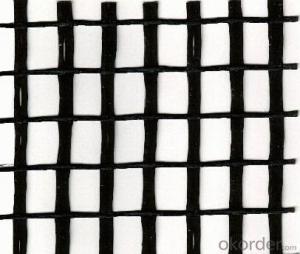

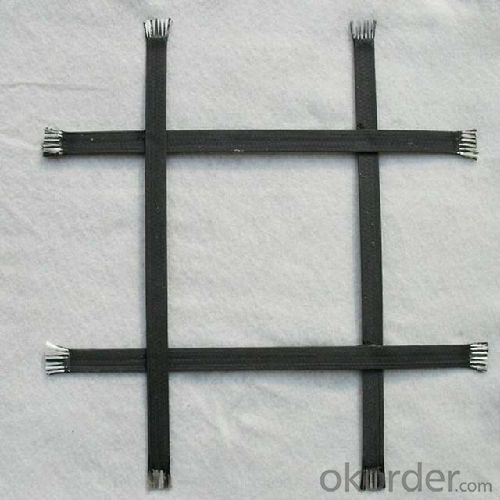

Fiberglass Geogrid Introduction

Fiberglass geogrid is a new excellent maeterial used for reinforcing road surface and base, it made by fiberglass filament, and covered by special solution. High longitudinal and horizontal strength, low elongation rate, anti-alkali and aging resistance, widely used in asphalt road surface, concrete road surface and reinforceing road base.

Main Feature of Fiberglass Geogrid

1.Tensile Strength (KN/m):

30X30KN/M,50x50KN/M,60X60KN/M,70X70KN/M,80X80KN/M

2. Elongation: 3%

3. Mesh Size: 25.4 x 25.4mm or 12.7x 12.7mm

4. Width: 1-6m

5.Temperature Resistance (Centigrade) : -100~290

6.Surface Processing: Modified asphalt or Polymer and self adhesive

7.Packing: with PE bag packing

Also detailed specification may be manufacturered according to your need.

if you are interest in our project, pleas contact me for further information.

Detail Specifications of Fiberglass Geogrid

Specification | 1×1 | 1×1 | 1×1 | 1×1 | 1×1 | 2×2 | 2×2 | |

Strength | Long . Horiz | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥60 | ≥80 |

≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥60 | ≥80 | ||

Percentage of Elongation | 4% | 4% | 4% | 4% | 4% | 4% | 4% | |

Size of Hole mm | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 12.7×12.7 | 12.7×12.7 | |

Flexibility | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width M | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | |

Temperature | -100200 | -100200 | -100200 | -100200 | -100200 | -100200 | -100200 | |

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: Are geogrids suitable for use in soil reinforcement for pipeline crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline crossings. They provide effective reinforcement by distributing loads and improving soil stability, reducing the risk of settlement or failure. Geogrids are designed to withstand high tensile forces and can enhance the performance and longevity of pipeline installations in various soil conditions.

- Q: How do geogrids help in soil reinforcement?

- Geogrids help in soil reinforcement by providing a strong and stable framework within the soil, preventing its movement and improving its load-bearing capacity. They act as a tensional element, distributing the applied loads and reducing the stress on the soil. This reinforcement helps in preventing soil erosion, improving slope stability, and enhancing the overall performance and longevity of various civil engineering structures.

- Q: Can geogrids be used in retaining walls for waterfront applications?

- Yes, geogrids can be used in retaining walls for waterfront applications. Geogrids are commonly used in such applications to reinforce and stabilize the soil behind the retaining wall, providing additional strength and preventing potential erosion or failure.

- Q: How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing reinforcement and stabilization to soil, reducing the need for excessive excavation and material usage.

- Q: Geogrid prices and geogrid manufacturers?

- 4, geogrid reinforced airport foundation can greatly improve the bearing capacity of the runway, to ensure the safety of aircraft landing5, geogrid can be used for garbage disposal, power plants, ash dam project, coal mine, metallurgy, green, enclosure and other fields6, the construction of soft foundation reinforcement, improve the overall bearing capacity of the foundation

- Q: The difference between steel plastic two-way geogrid and steel plastic geogrid

- One way steel plastic geogrid is longitudinal tension requirements, only the detection of longitudinal tension.

- Q: How do geogrids improve the stability of mechanically stabilized earth walls?

- Geogrids improve the stability of mechanically stabilized earth walls by providing reinforcement and confinement to the soil. They increase the tensile strength of the wall system, redistributing applied loads and preventing excessive deformation. The geogrids also enhance the overall stability by minimizing soil erosion and promoting better compaction, resulting in a more robust and durable structure.

- Q: Can geogrids be used in ground reinforcement for sports fields?

- Yes, geogrids can be used in ground reinforcement for sports fields. Geogrids provide stability, improve load-bearing capacity, and prevent soil erosion, making them a suitable choice for reinforcing the ground in sports fields and ensuring a durable playing surface.

- Q: How do geogrids help in reducing the need for excavation and replacement of poor soils?

- Geogrids help in reducing the need for excavation and replacement of poor soils by providing reinforcement to the soil, increasing its load-bearing capacity. This reinforcement allows for the construction of structures on weak or unstable soil without the need for extensive excavation and replacement. Geogrids distribute the load more evenly, reducing soil movement and potential settlement, thus eliminating the need for costly and time-consuming excavation and replacement processes.

- Q: How do geogrids enhance the performance of reinforced soil slopes?

- Geogrids enhance the performance of reinforced soil slopes by providing tensile strength and increasing the stability of the soil structure. They act as a reinforcement material, distributing loads and reducing soil movement, preventing erosion and slope failure. Additionally, geogrids improve soil compaction and drainage, enhancing the overall performance and durability of reinforced soil slopes.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Geo Cells and Geogrids - Bitumen Coated Fiberglass Geogrid with Certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords