Neoly Geocells Fiberglass Geogrid High Intensity Low Elongation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Products Profile

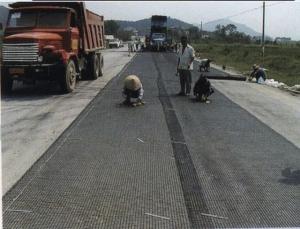

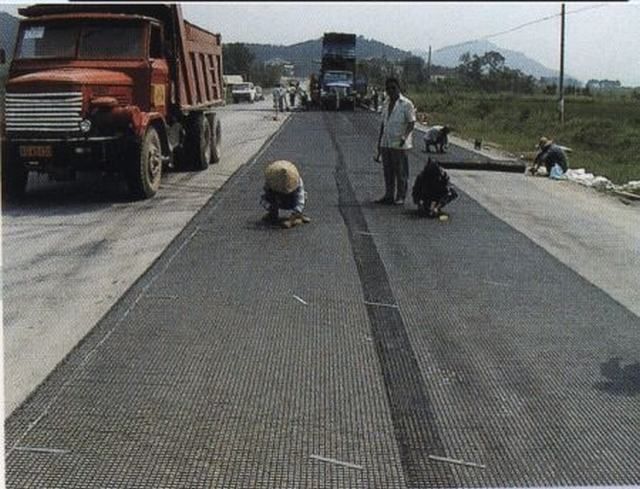

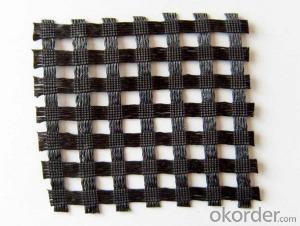

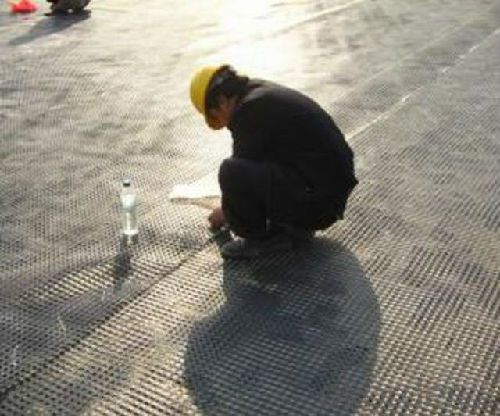

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

Fiberglass Geogrid Products Features

It is characterized by high tensile strength in axial and lateral directions low stretch rate, alkaili-resistance, low temperature-assistance as well as convenience in construcion and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Fiberglass Geogrid Products Advantages

High strength

High modulus

Low temperature resistance

Very convenience in construction

Very competitve price

Fiberglass Geogrid Product Application:

1. It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2. it used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction;

3. it is used in road expansion and improvement project and crack caused by old and new combination position and uneven sedimentation;

4. it is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base;

5. it is used for preventing contraction crack caused by new road semi-rigid base layer, and reinforcing and preventing road surface crack caused by foundation crack reflection

Fiberglass Geogrid Technical Standard (standard type):

Geotechnological grid of fiberglass | |||||||

Performance\specification | EGA25-25 | EGA30-30 | EGA40-40 | EGA50-50 | EGA80-80 | EGA200-200 | |

Intensity | Longitudinal | 25 | 30 | 40 | 50 | 80 | 200 |

Crosswise | 25 | 30 | 40 | 50 | 80 | 200 | |

Break elongation ratio% | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |

Grid(mm) | 12.7*12.7 25.4*25.4 | ||||||

Breadth(m) | 1—6 | 1—6 | 1—6 | 1—6 | 1—6 | 1—6 | |

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: What is a geotextile mattress?

- Composite geotextile is also called soft mattress, soft soft row row. The upper filter geotextile layer, lower layer woven cloth layer, upper and lower two layers sewn into several units, each unit filling sand is formed around the main rib and frame shape auxiliary rib, the main vertical rib in the flow direction, the auxiliary rib along the flow direction, the composite geotextile soft volleyball has the advantages of good flexibility, in the process of riprap, can automatically adjust the overall shape, form a good protective line and the bearing capacity of stone, with good protection function

- Q: What is the difference between woven and non-woven geogrids?

- Woven geogrids are made by weaving individual yarns together, creating a grid-like structure. Non-woven geogrids, on the other hand, are manufactured by bonding or interlocking fibers together through mechanical, thermal, or chemical processes. The key difference is in the manufacturing process, which results in woven geogrids being stronger and more rigid, while non-woven geogrids tend to be more flexible and have higher tensile strength. Additionally, woven geogrids are generally used in applications that require high load-bearing capacity, while non-woven geogrids are often used for soil stabilization and separation purposes.

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications depends on various factors such as soil type, load requirements, and installation method. Generally, square or rectangular aperture shapes are preferred for applications involving stabilization and reinforcement of soils, while triangular or diamond-shaped apertures are more suitable for applications requiring high tensile strength and flexibility. It is crucial to consult geosynthetic experts or manufacturers to determine the most appropriate geogrid aperture shape for a specific project.

- Q: Longitudinal and transverse tensile strength more than 60kn/m which has several geogrid

- The key depends on which side you choose, the choice is different.

- Q: Can geogrids be used for reinforcement in railway tracks?

- Yes, geogrids can be used for reinforcement in railway tracks. Geogrids are a type of geosynthetic material that can provide additional strength and stability to the track structure. They can help distribute loads, prevent track settlement, and improve overall track performance.

- Q: How do geogrids help in reducing the use of natural resources?

- Geogrids help in reducing the use of natural resources by providing reinforcement and stabilization to soil structures. They allow for the use of less soil and aggregate materials in construction projects, reducing the need for excavation and mining of natural resources. Additionally, geogrids improve the durability and longevity of structures, reducing the need for frequent repairs or replacements, further conserving natural resources.

- Q: How do geogrids help in reducing settlement of foundations?

- Geogrids help in reducing settlement of foundations by providing additional tensile strength and stability to the soil. They act as a reinforcement layer, distributing the load more evenly across the foundation, thus minimizing settlement. Additionally, geogrids enhance the overall stability of the soil, preventing lateral movement and potential soil erosion, which can also contribute to settlement.

- Q: What are the design guidelines for geogrid-reinforced structures?

- The design guidelines for geogrid-reinforced structures typically include factors such as selecting the appropriate geogrid material, determining the required strength and stiffness properties, spacing and orientation of the geogrid layers, and proper connection details. Additionally, the guidelines may address slope stability, settlement control, and construction considerations to ensure the overall stability and performance of the reinforced structure.

- Q: How do geogrids help in reducing the environmental impact of construction?

- Geogrids help in reducing the environmental impact of construction by providing soil stabilization and reinforcement, reducing the need for excessive excavation and material usage. This results in minimized disturbance to natural habitats, reduced waste generation, and lower carbon emissions, ultimately promoting sustainable construction practices.

- Q: Application and effect of steel plastic geogrid

- The general treatment of soft foundation filling height greater than 4 meters by.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Neoly Geocells Fiberglass Geogrid High Intensity Low Elongation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords