Fiberglass Geogrid 100KN/100KN for Constructional Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

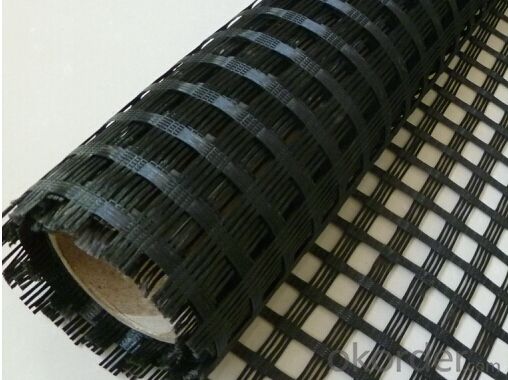

1.Description of Fiberglass Geogrid 100KN/100KN

CMAX fiberglass geogrid is made from glass fiber by weaving technology and coating treatment.

2.Specification of Fiberglass Geogrid 100KN/100KN

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

3.Technical Data Sheet of Fiberglass Geogrid 100KN/100KN

Item | CMAX30-30 | CMAX50-50 | CMAX80-80 | CMAX100-100 | CMAX120-120 | CMAX150-150 | |

Mesh Size(mm) | 25.4 x 25.4 or 12.5 x 12.5 or 50.8x 50.8 | ||||||

Breaking strength | Warp direction | 30 | 50 | 80 | 100 | 120 | 150 |

Across warp | 30 | 50 | 80 | 100 | 120 | 150 | |

Elongation at break % | Warp direction | 4 | |||||

Across warp | 4 | ||||||

Thermal tolerance (℃) | -100 ~280 | ||||||

Width(m) | 6 | ||||||

4.Property of Fiberglass Geogrid 100KN/100KN:

1). High strength, low elongation;

2). Heat-resistant, high modulus.

3). Light weight, good flexibility.

4). Anti-erosion, long life time.

5.Application of Fiberglass Geogrid 100KN/100KN

1). Roadbed reinforcement, prevent road surface crack.

2). Road reconstruction

3). Soft soil reinforcement, improve road whole bearing capacity and prevent crack.

FAQ :

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

4. Do you accept third party test?

Yes, we can accept any third party test before shipment, like SGS, TRI, etc.

- Q: How much is the horizontal overlap length of the steel plastic geogrid

- 10-15cm if the geogrid is a longitudinal lap not less than 20cm reference geogrid construction technology

- Q: What are the factors that affect the long-term oxidation resistance of geogrids?

- The factors that affect the long-term oxidation resistance of geogrids include the material composition and quality of the geogrid, exposure to environmental conditions such as temperature and moisture, presence of chemicals or pollutants in the surrounding environment, and the design and installation of the geogrid in the application.

- Q: Are geogrids effective in stabilizing embankments for pipeline crossings?

- Yes, geogrids are effective in stabilizing embankments for pipeline crossings. Geogrids provide reinforcement and enhance the stability of the soil, preventing erosion and minimizing settlement. They distribute loads efficiently, increasing the overall strength of the embankment and ensuring long-term stability for pipeline crossings.

- Q: Can geogrids be used in erosion control on slopes and hillsides?

- Yes, geogrids can be used in erosion control on slopes and hillsides. Geogrids are widely used for reinforcement and stabilization purposes in such areas to prevent soil erosion and retain the stability of the slope or hillside. They provide additional support to the soil, reducing the risk of landslides and erosion by improving the structural integrity of the slope.

- Q: How do geogrids improve the performance of flexible retaining walls?

- Geogrids improve the performance of flexible retaining walls by providing reinforcement and stability to the soil behind the wall. They help distribute the lateral pressure from the retained soil, reducing the risk of wall failure. Additionally, geogrids increase the overall strength of the wall, allowing it to withstand greater loads and forces.

- Q: How many grams per square meter of 15KN Geotextiles

- The square Mick weight of polyester staple fiber geotextiles 15KN is 500 grams

- Q: Are geogrids suitable for reinforcement of mechanically stabilized earth slopes?

- Yes, geogrids are suitable for the reinforcement of mechanically stabilized earth slopes. Geogrids provide effective reinforcement by distributing tensile forces and enhancing soil stability. They help to prevent slope failure, control erosion, and increase overall slope strength. Additionally, geogrids are easy to install and have a long lifespan, making them a reliable choice for reinforcement in mechanically stabilized earth slopes.

- Q: What is the effect of installation damage on geogrid performance?

- Installation damage can have a significant impact on the performance of geogrids. Damage during installation can result in reduced tensile strength, deformation, and compromised stability of the geogrid. This can lead to a decreased ability to reinforce and stabilize soil, ultimately affecting the overall effectiveness of the geogrid in its intended application. Therefore, it is crucial to handle and install geogrids carefully to minimize any potential damage that could affect their performance.

- Q: Do geogrids require any maintenance?

- Yes, geogrids require minimal maintenance. Periodic inspections should be conducted to ensure they are functioning properly and not damaged. Any debris or sediment buildup should be removed, and any damaged geogrids should be repaired or replaced. Overall, regular maintenance is recommended to ensure the longevity and effectiveness of geogrids.

- Q: How to do this in the geogrid in the retaining wall? Is there any remedy?

- Thermal stability - the melting temperature of the glass fiber is above 1000 DEG C, which ensures the stability of the fiberglass geogrid in the paving operation.

Send your message to us

Fiberglass Geogrid 100KN/100KN for Constructional Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords