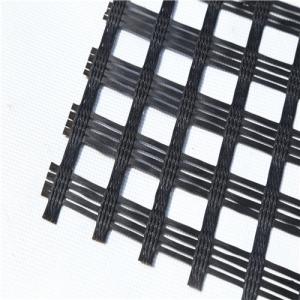

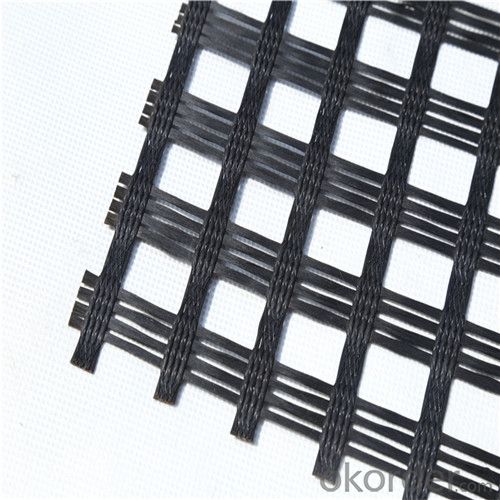

Fiberglass Woven Geogrid for Reforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Description

Fiberglass Geogrid is a kind of planar mesh using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives fully play of yarn strength and improves

Its mechanical property. It is coated with asphalt making full protection of the fiberglass matrix and greatly improving its wear and shear resistance.

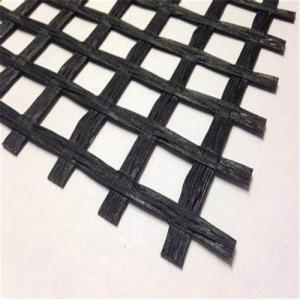

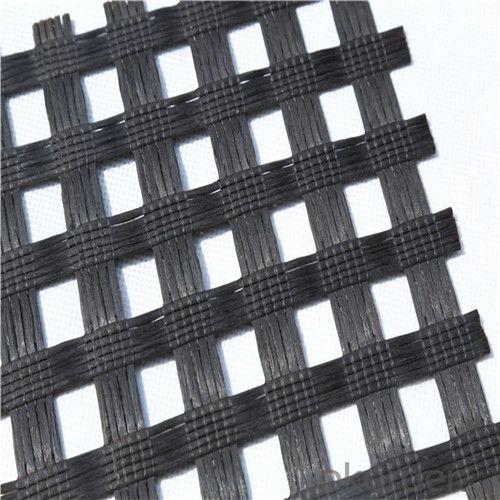

Fiberglass Geogrid Specification

Tensile Strength: 25-25KN, 30-30KN, 50-50KN, 80-80KN, 100-100KN, 120-120KN,

Roll Size: 3.95x100m, as request,

Fiberglass Geogrid Property:

1) High strength, low elongation;

2) Heat-resistant, high modulus.

3) Light weight, good flexibility.

4) Anti-erosion, long life time.

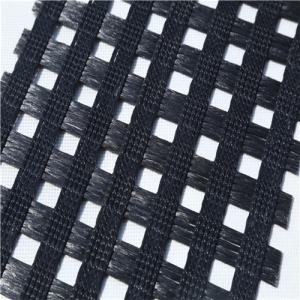

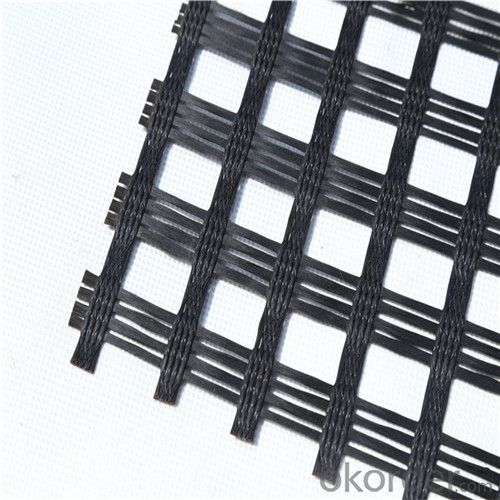

Fiberglass Geogrid Application

1) Roadbed reinforcement, prevent road surface crack.

2) Road reconstruction

3) Soft soil reinforcement, improve road whole bearing capacity and prevent crack.

Fiberglass Geogrid

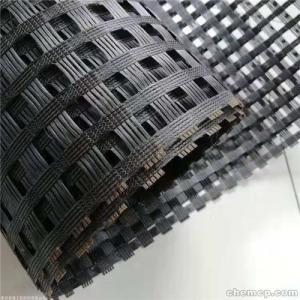

Packaging Details: PP bags or PE film. Or Packed as customers' requests;

Delivery Detail: 10-20days after the payment received.

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: What are the benefits of using geogrids in retaining walls?

- Geogrids offer several benefits in retaining walls, including increased stability, improved load distribution, and enhanced soil reinforcement. These geosynthetic materials help to prevent soil erosion and shifting, thereby increasing the overall strength and durability of the retaining wall. Additionally, geogrids promote proper drainage and reduce the risk of water build-up behind the wall, which can further enhance its performance and longevity.

- Q: What does the geotextile 200# mean?

- Geotextile is made of synthetic fiber by acupuncture or woven into a permeable geosynthetic material. The finished product is cloth, the general width of 4-6 meters, the length of 50-100 metersGeneral specifications from the arbitrary choice between 80g/ square meters ~800g/ square metersOf course, the high requirements of the occasion, there is a high weight of Geotextile

- Q: The effect of steel and plastic grille in steel and plastic grille

- 3 steel plastic grille for the construction of convenient, time-saving, labor-saving, shorten the construction period, reduce maintenance costs.4 steel plastic grille used to prevent cracks in culvert.5 plastic steel plastic geogrid is used to enhance soil slope and prevent soil erosion.

- Q: What is the distance between the waterproof plate and the top of the tunnel? What are the relevant provisions of this specification?

- Geotextile, composite geomembrane, bentonite waterproof blanket, a new type of three-dimensional mesh pad, geocell and other engineering materials

- Q: Are geogrids suitable for use in reinforced steep slopes?

- Yes, geogrids are suitable for use in reinforced steep slopes. Geogrids provide additional strength and stability to the soil, preventing erosion and maintaining the integrity of the slope. They are designed to withstand high tensile forces, making them ideal for reinforcing steep slopes and preventing soil movement.

- Q: Geogrid what to do

- Longitudinal transverse tension

- Q: What are the design considerations for geogrid-reinforced embankments?

- Some key design considerations for geogrid-reinforced embankments include the selection of appropriate geogrid material, determining the required strength and stiffness of the geogrid, considering the effects of construction and installation techniques on the performance of the reinforcement, assessing the soil properties and slope stability of the embankment, and ensuring proper connection and interaction between the geogrid and the embankment materials. Additionally, factors such as long-term durability, potential for differential settlement, and environmental considerations should also be taken into account during the design process.

- Q: How do geogrids improve the performance of geosynthetic clay liners?

- Geogrids improve the performance of geosynthetic clay liners by providing added stability and reinforcement. They distribute loads more evenly, reducing the risk of liner deformation and maintaining its integrity. Geogrids also enhance the liner's tensile strength, preventing cracks and enhancing its resistance to shear forces. Overall, geogrids enhance the durability and performance of geosynthetic clay liners, increasing their effectiveness in various civil engineering applications.

- Q: Can geogrids be used in reinforcement of soil-cement mixtures?

- Yes, geogrids can be used in the reinforcement of soil-cement mixtures. Geogrids are commonly used to improve the strength and stability of soil-cement composites by distributing loads, reducing settlement, and preventing cracking. They enhance the overall performance of soil-cement mixtures and are widely utilized in various civil engineering applications.

- Q: Can geogrids be used in soil reinforcement for landslide mitigation?

- Yes, geogrids can be used in soil reinforcement for landslide mitigation. Geogrids are commonly used to enhance the stability and strength of soil, including in slope stabilization and landslide prevention. They are placed within the soil mass to provide reinforcement and improve its load-bearing capacity, reducing the risk of landslides.

Send your message to us

Fiberglass Woven Geogrid for Reforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords