Fiberglass Geogrid for Road Reforcement Construstion

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

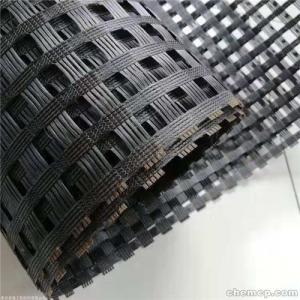

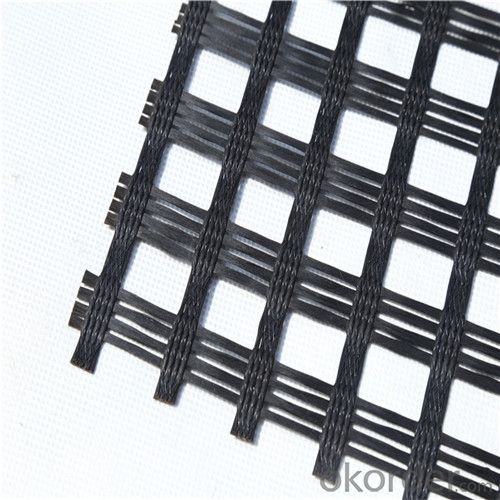

Fiberglass Geogrid Description

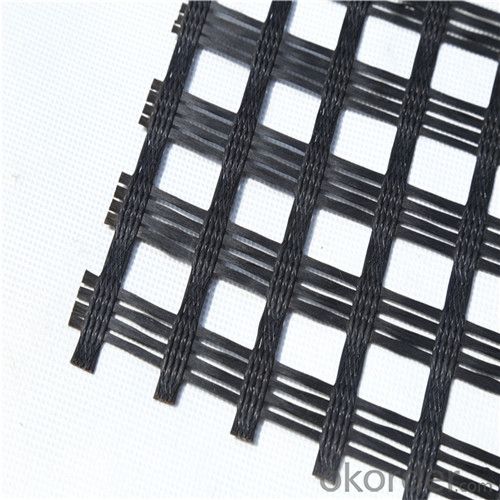

Fiberglass Geogrid is a kind of planar mesh using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives fully play of yarn strength and improves.

Its mechanical property. It is coated with asphalt making full protection of the fiberglass matrix and greatly improving its wear and shear resistance.

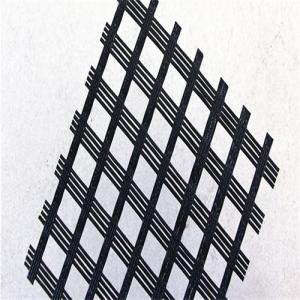

Fiberglass Geogrid Specification

Tensile Strength: 25-25KN, 30-30KN, 50-50KN, 80-80KN, 100-100KN, 120-120KN,

Roll Size: 3.95x100m, as request,

Fiberglass Geogrid Property:

1) High strength, low elongation;

2) Heat-resistant, high modulus.

3) Light weight, good flexibility.

4) Anti-erosion, long life time.

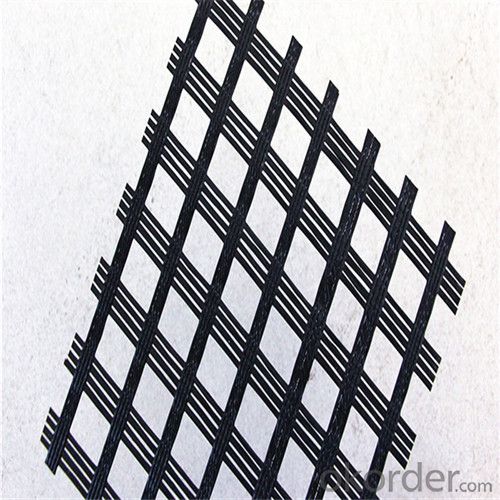

Fiberglass Geogrid Application

1) Roadbed reinforcement, prevent road surface crack.

2) Road reconstruction

3) Soft soil reinforcement, improve road whole bearing capacity and prevent crack.

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: How are geogrids manufactured?

- Geogrids are manufactured through a process known as extrusion, where high-density polyethylene (HDPE) or polypropylene (PP) materials are melted and forced through a die to create a continuous mesh-like structure. This structure is then stretched in different directions to orient the polymer molecules, giving the geogrid its strength and stiffness. The material is then cooled, cut to the desired length, and rolled into large rolls for distribution and use in various geotechnical applications.

- Q: Do geogrids affect the permeability of soil?

- Yes, geogrids can affect the permeability of soil. Geogrids are typically used in civil engineering to reinforce soil and increase its strength. When installed, geogrids create a network of interconnected channels that enhance the drainage system within the soil. This improved drainage can result in increased permeability, allowing water to flow more freely through the soil.

- Q: How do geogrids improve the performance of geosynthetic-reinforced foundations?

- Geogrids improve the performance of geosynthetic-reinforced foundations by providing increased tensile strength and stability to the soil. They act as a reinforcement layer, distributing loads more evenly and reducing the potential for soil settlement or failure. Additionally, geogrids enhance the overall bearing capacity of the foundation, ensuring better long-term performance and reducing the risk of structural damage.

- Q: How do geogrids enhance the stability of steep road embankments?

- Geogrids enhance the stability of steep road embankments by providing reinforcement to the soil. They are installed within the embankment to distribute the tensile forces and prevent soil erosion or slippage. The geogrids act as a stabilizing layer, improving the overall strength and integrity of the embankment, making it more resistant to lateral movement and increasing its load-bearing capacity.

- Q: How do geogrids improve the load distribution in paved surfaces?

- Geogrids improve the load distribution in paved surfaces by providing reinforcement and enhanced structural support. They distribute the applied loads over a wider area, reducing stress concentration and preventing the development of cracks and deformations. Additionally, geogrids increase the overall stiffness of the pavement system, enhancing its load-bearing capacity and extending its lifespan.

- Q: What is the elongation of fiberglass geogrid?

- Hope to help you

- Q: What is the lifespan of geogrids in typical applications?

- The lifespan of geogrids in typical applications can vary depending on various factors such as the specific type and quality of the geogrid, the environmental conditions, and the level of stress or load applied to the geogrid. However, in general, geogrids are designed to have a long lifespan ranging from 20 to 50 years or even more in some cases. Regular maintenance and inspection can help extend the lifespan of geogrids and ensure their continued effectiveness in their intended applications.

- Q: Are geogrids suitable for use in reinforced retaining walls?

- Yes, geogrids are suitable for use in reinforced retaining walls. Geogrids provide effective reinforcement by improving soil stability, preventing wall failure, and increasing overall structural integrity of the retaining wall. They enhance the load-bearing capacity of the wall and help distribute the forces exerted by the retained soil, making it a reliable and durable solution for reinforced retaining walls.

- Q: Which is better than geotextile and geogrid

- The strength of the geogrid is much larger than that of geotextile, but the effect of geotextile on the road to prevent reflection crack is obviously stronger than that of Geogrid

- Q: Where is the best geogrid to do?

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Two way, single main look at the design, there are many domestic manufacturers of geotechnical materials, product quality depends on the order contract, to meet the national standards have a lot of. It's all about there.

Send your message to us

Fiberglass Geogrid for Road Reforcement Construstion

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords