High Strength HDPE Uniaxial Geogrid for Europe Geogrids Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

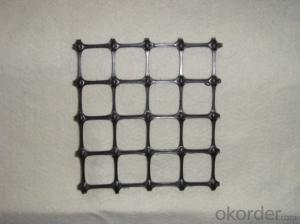

HDPE Uniaxial Geogrid Introduction

25-25KN,30-30KN,50-50KN,80-80KN,100-100KN,120-120KN,150-150KN,200-200KN

Width≤6m; Length 50m or as requested

HDPE Uniaxial Geogrid Features

1. In high tensile strength

2. Low elongation

3. Anti-erosion, anti-aging

4. Light weight, structural uniformity, easy for construction

5. Flame retardant, anti-static, good overall performance, easy for mechanized operation

6. Good affinity with base materials

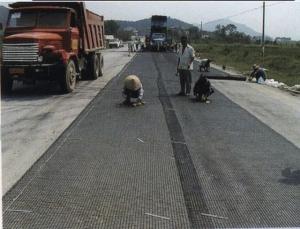

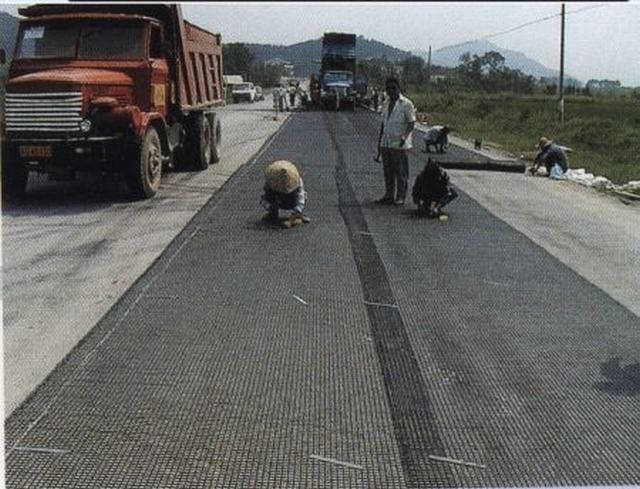

HDPE Uniaxial Geogrid Application

ation

1. Roadbed reinforcement in highway, railway and municipal road

2. Reinforcement and separation in dam and river, improving soft soil bearing capacity and stability

3. Roadbed slope reinforcement, retaining wall reinforcement

HDPE Uniaxial Geogrid Specification

Technical Data

Item | Specification and Index | ||||||

30-30 | 35-35 | 50-50 | 80-80 | 100-100 | 125-125 | 150-150 | |

Limit Tensile Strength (MD&TD)(KN/m) | ≥30 | ≥35 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 |

Elongation at nominal tensile strength (MD&TD)(%) | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤14 |

Tensile Strength@2% elongation(MD&TD)(KN/m) | ≥10 | ≥12 | ≥17 | ≥28 | ≥35 | ≥43 | ≥52 |

Tensile Strength@5% elongation(MD&TD)(KN/m) | ≥20 | ≥24 | ≥34 | ≥56 | ≥70 | ≥86 | ≥104 |

Production Standard : JT/T480-2002 | |||||||

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: How do geogrids help in reducing carbon footprint in construction projects?

- Geogrids help reduce carbon footprint in construction projects by enabling the use of locally available materials instead of importing heavy construction materials, which reduces transportation emissions. Additionally, geogrids enhance the stability and load-bearing capacity of soil, reducing the need for extensive excavation and the use of concrete and steel, which are carbon-intensive materials. Moreover, geogrids can extend the lifespan of roads and structures, reducing the frequency of repairs and reconstruction, thereby minimizing the carbon emissions associated with construction activities.

- Q: What are the factors that affect the performance of geogrids under cyclic loading?

- There are several factors that can affect the performance of geogrids under cyclic loading. These include the type and quality of the geogrid material, the design and installation of the geogrid, the magnitude and frequency of the cyclic loading, the properties of the surrounding soil, and the environmental conditions. Additionally, factors such as aging, degradation, and maintenance of the geogrid can also impact its performance under cyclic loading.

- Q: What kind of products are the high strength and high strength micro - pile geocell? Introduce some specific details. Thank you

- At the welding point, there is a unique reinforcing rib combined to produce the effect of micro pile

- Q: The difference between two way steel plastic grille and one way steel plastic grille

- Bi directional steel plastic geogrid is both vertical and horizontal tension requirements, have to do pull test

- Q: What are the design considerations for geogrid-reinforced embankments?

- Some key design considerations for geogrid-reinforced embankments include the selection of appropriate geogrid material, determining the required strength and stiffness of the geogrid, considering the effects of construction and installation techniques on the performance of the reinforcement, assessing the soil properties and slope stability of the embankment, and ensuring proper connection and interaction between the geogrid and the embankment materials. Additionally, factors such as long-term durability, potential for differential settlement, and environmental considerations should also be taken into account during the design process.

- Q: Can geogrids be used in reinforcement of embankments on expansive clays?

- Yes, geogrids can be used in the reinforcement of embankments on expansive clays. Geogrids are commonly used in such scenarios to improve the stability and performance of embankments by providing tensile strength and preventing soil movement. By distributing the load and reducing the potential for settlement, geogrids effectively reinforce embankments on expansive clays.

- Q: What is the recommended geogrid junction spacing for specific applications?

- The recommended geogrid junction spacing for specific applications varies depending on factors such as soil conditions, load requirements, and project specifications. It is best to consult with a geotechnical engineer or refer to industry guidelines and standards to determine the appropriate geogrid junction spacing for a specific application.

- Q: What is the recommended geogrid connection method for specific applications?

- The recommended geogrid connection method for specific applications depends on factors such as the type of soil, slope angle, and expected load conditions. Some common geogrid connection methods include mechanical connectors, welded connections, and soil wrap-around techniques. It is important to consult with a geotechnical engineer or follow manufacturer's recommendations to determine the most suitable connection method for a specific application.

- Q: How do geogrids help with load distribution?

- Geogrids help with load distribution by distributing the applied loads over a wider area, thereby reducing the concentration of stress on the underlying soil or pavement. They act as a reinforcement by interlocking with the surrounding soil or aggregate, improving the overall stability and load-bearing capacity of the structure.

- Q: Each side of geogrid is not less than 3 meters, what does it mean?

- At present, the largest width of single geogrid is 6 meters

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Strength HDPE Uniaxial Geogrid for Europe Geogrids Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords