Tensar Biaxial PP Geogrid for Foundation Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

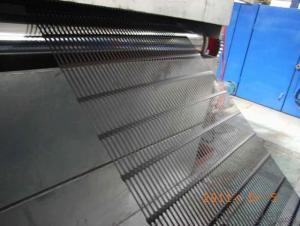

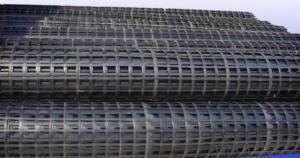

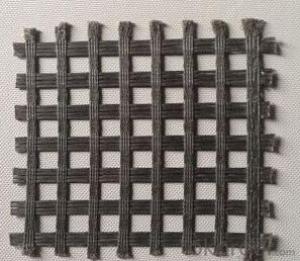

PP Geogrid Prodcut Introduction

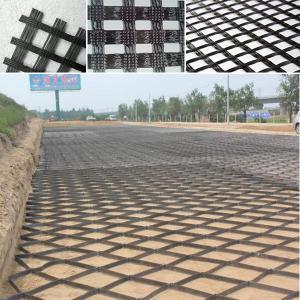

PP Geogrid mainly used in highway and railroad to reduce the subsiding difference ofthe roadbed and bridgehead, lower the vibration of the vehicles and theroadbed, slower the roadbed structure distortion to guarantee the security and comfort.

To lay the geogrid in the backfill soil can increase the shearing strength and the whole character in middle terms, reduce the mid-term filling quantity, make the soft base more convenient, lower the construction cost.

When used in the dam design, it can be as the muscle structure to improve the bearing distortion performance of the dam to avoid breaking.

PP Geogrid Prodcut Features

High tensile strength

Low elongation

Excellent temperature resistant

Good anti-aging

Good alkali-resistance

PP Geogrid Prodcut Technical Data

Item | Art. No. | 010301 | 010302 | 010303 | 010304 | 010305 |

Specs | 15-15 | 20-20 | 30-30 | 40-40 | 45-45 | |

Unit weight,g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | 550±50 | |

Width,m | 4.0+0.2/-0 | |||||

Tensile strength(MD), kN/m≥ | 15 | 20 | 30 | 40 | 45 | |

Tensile strength (CD),kN/m≥ | 15 | 20 | 30 | 40 | 45 | |

Elongation(MD),%≤ | 13 | |||||

Elongation(CD),%≤ | 16 | |||||

Tensile strength at 2% strain(MD),kN/m≥ | 5 | 8 | 11 | 13 | 16 | |

Tensile strength at 2% strain(CD),kN/m≥ | 7 | 10 | 13 | 15 | 20 | |

Tensile strength at 5% strain(MD),kN/m≥ | 8 | 10 | 15 | 16 | 25 | |

Tensile strength at 5% strain(CD),kN/m≥ | 10 | 13 | 15 | 20 | 22 | |

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: How do geogrids help in reducing construction labor requirements?

- Geogrids help in reducing construction labor requirements by providing reinforcement and stability to the soil, which eliminates the need for excessive excavation, backfilling, and compaction. This saves time and effort for the construction workers, as geogrids can bear heavy loads and prevent soil movement, reducing the need for extensive manual labor.

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are flexible and durable materials that can reinforce soil and improve its stability. In seismic zones, where the ground is prone to shaking and instability during earthquakes, geogrids can effectively enhance soil resistance to lateral movement, reduce soil liquefaction, and provide greater overall stability to structures. Their ability to distribute loads and increase soil confinement makes them highly suitable for use in seismic zones.

- Q: Who knows how much the staggered distance of the lap joint of the geogrid is?

- When the geotextile is used as the anti filter layer, it should be laid on the bottom and the sides of the trench wall, and the top cover of the geotextile is reserved,

- Q: What are the factors affecting the design of geogrid-reinforced structures?

- The factors affecting the design of geogrid-reinforced structures include the type and properties of the soil, the load and magnitude of the forces acting on the structure, the desired level of stability and performance, the site conditions and constraints, and the specific design standards and guidelines applicable to the project.

- Q: How do geogrids improve the performance of retaining walls?

- Geogrids improve the performance of retaining walls by providing reinforcement to the soil behind the wall, increasing its stability and resistance to lateral forces. This prevents excessive movement, settlement, and potential failure of the retaining wall.

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can impact the installation and survivability of geogrids in harsh environments. Firstly, the quality and strength of the geogrid material itself play a significant role. Geogrids made from durable and high-quality materials are more likely to withstand harsh conditions. Secondly, the installation technique is crucial, as improper installation can lead to geogrids being damaged or dislodged. The type and condition of the subgrade also affect the geogrid's survivability, as a stable and well-prepared subgrade provides a solid foundation for the geogrids. Additionally, environmental factors such as extreme temperatures, moisture levels, and chemical exposure can impact the long-term performance and durability of geogrids in harsh environments.

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Because the main force borne by the steel wire, if it is false, the consequences can be disastrous ah!

- Q: How much is the steel plastic geogrid?

- The steel plastic geogrid is also called the steel plastic grille, the steel plastic composite geogrid, a lot of also called the plastic steel grille (a kind of misreading), is a kind of geogrid. The price of steel plastic geogrid is divided according to the model, the model of steel plastic geogrid has 30KN, 40KN, 50KN, 60KN, 70KN, and so on, the maximum can reach 150KN. Commonly used models of steel plastic geogrid prices are as follows:

- Q: GDZ150 type one-way steel plastic welding geogrid D in the construction of the roadbed is horizontal paving also vertical spread?

- Of course it is perpendicular to the direction of the route

- Q: Can geogrids be used in reinforcement of underground tunnels and caverns?

- Yes, geogrids can be used in the reinforcement of underground tunnels and caverns. Geogrids are high-strength, synthetic materials that are commonly used for soil stabilization and reinforcement. They can provide additional support to the surrounding soil or rock mass, increasing the overall stability and strength of the underground structures. By distributing the loads and reducing stress concentrations, geogrids help prevent deformation and potential collapse of tunnels and caverns.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Tensar Biaxial PP Geogrid for Foundation Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords