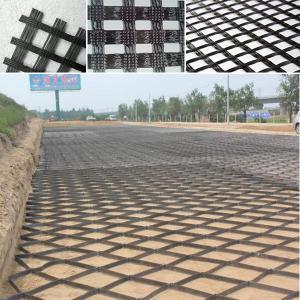

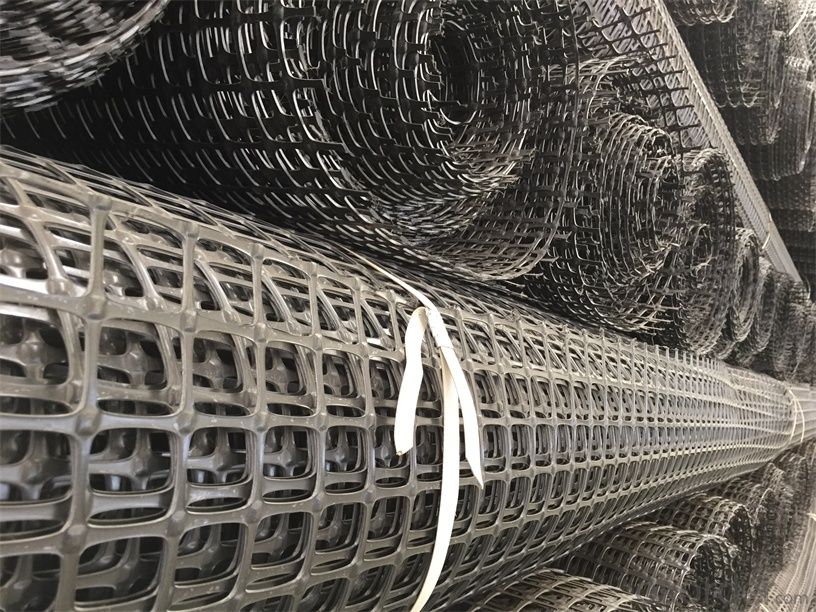

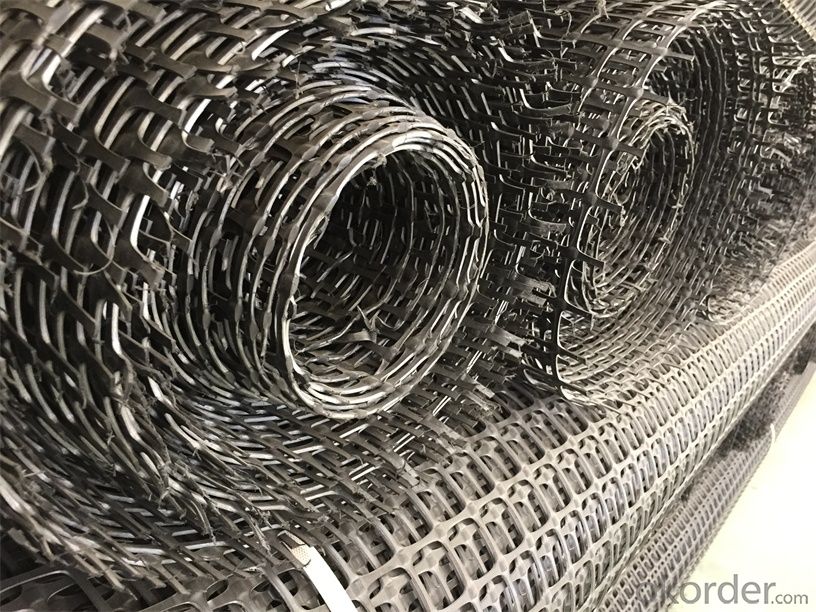

High Tensile Strength Warp Knitted PP Biaxial Geogrid for Soil Stabilisation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Geogrid standard geogrid price geogrid role

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: How do geogrids improve the performance of soil retaining structures?

- Geogrids improve the performance of soil retaining structures by providing reinforcement and stability to the soil. They distribute the applied loads more evenly, reduce soil movement and prevent the occurrence of sliding or failure. Additionally, geogrids increase the bearing capacity of the soil, enhance drainage, and improve overall durability and longevity of the retaining structures.

- Q: Can geogrids be used in reinforcement of mechanically stabilized slopes?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized slopes. Geogrids are often used to improve the stability and strength of slopes by providing additional reinforcement to the soil. They help to distribute the loads and reduce lateral movement, thus preventing slope failure. Additionally, geogrids can enhance the overall performance and longevity of mechanically stabilized slopes by improving their resistance to erosion and environmental factors.

- Q: Can geogrids be used in stabilization of canal banks?

- Yes, geogrids can be used in the stabilization of canal banks. Geogrids are engineered materials that provide reinforcement and stability to soil. They can be used as a reinforcing element in the construction of canal banks to prevent erosion, improve slope stability, and increase load-bearing capacity. By distributing the forces exerted by water flow and preventing soil movement, geogrids help to maintain the integrity and stability of canal banks.

- Q: Can geogrids be used in mining tailings management?

- Yes, geogrids can be used in mining tailings management. Geogrids are commonly utilized in mining operations to reinforce and stabilize soil and tailings materials. They can be installed to improve the strength, stability, and resistance of tailings dams or containment structures, reducing the risk of slope failure or leakage. Additionally, geogrids can enhance the dewatering process, facilitating the consolidation and compaction of tailings for improved management and disposal practices.

- Q: Are geogrids resistant to biological fouling?

- Yes, geogrids are generally resistant to biological fouling. Geogrids are made from materials that are not easily degradable, such as high-density polyethylene (HDPE) or polypropylene (PP), which makes them less susceptible to colonization by organisms and reduces the likelihood of biological fouling. Additionally, geogrids often have a smooth surface that makes it difficult for biofilms or other organic matter to adhere to the grid. However, it is important to note that while geogrids are resistant to biological fouling, they are not completely immune, and regular inspection and maintenance may be required to prevent any potential buildup of organic matter.

- Q: Can geogrids be used in ground reinforcement for military installations?

- Yes, geogrids can be used in ground reinforcement for military installations. Geogrids are often employed in various civil engineering applications, including military projects, to enhance soil stability, provide load-bearing support, and improve overall ground reinforcement. They are effective in reinforcing and stabilizing soil, which is essential for military installations that require durable and resilient foundations to withstand heavy equipment, traffic, and potential ground disturbances. Geogrids can also assist in reducing soil erosion, enhancing slope stability, and minimizing the risk of ground movement or settlement, making them a valuable tool in military construction and infrastructure projects.

- Q: GDZ150 type one-way steel plastic welding geogrid D in the construction of the roadbed is horizontal paving also vertical spread?

- The direction of the pulling force is consistent with the direction of the road extension

- Q: Who knows the laying method of geogrid?

- Roller compaction of C. rubber tyred roller.D. 50? 0,.3mm of the fixed iron sheet, the requirements of flat angle, the edge of the appropriate chamfer treatment, 2 inch steel nails (high quality cement nails)When the e nail fixation method is used for laying fiberglass geogrid, one end is fixed on the lower layer of the structure of the asphalt layer which has been sprayed with a fixed iron sheet and a nail. When the grating is tensioned longitudinally, the glass fiber is in a straight and tight state.

- Q: How do geogrids help in reducing the risk of foundation settlement?

- Geogrids help in reducing the risk of foundation settlement by providing additional support and stability to the soil. They act as a reinforcement material, spreading the load of the foundation more evenly and preventing excessive settlement. Geogrids also help to confine the soil particles, preventing lateral movement and soil erosion, which can further contribute to foundation settlement.

Send your message to us

High Tensile Strength Warp Knitted PP Biaxial Geogrid for Soil Stabilisation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords