PP/HDPE One-Way Plastic Geogrids for Asphalt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

One-Way Plastic Geogrid Products

Products overview:

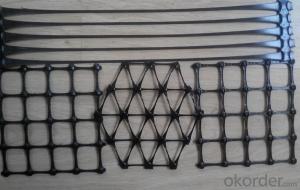

Unidirectional geogrid is made of polymer by extrusion pressure into sheet rules of mesh again, then the longitudinal tensile and into. The directional linear polymer into state and in the process of uniform distribution, long oval mesh nodes with high intensity is the structure integrity. This kind of structure has a very high tensile strength and tensile modulus, especially my company this kind of product is more than the international level of high early (elongation at 2% to 2%), tensile strength and tensile modulus. To the soil provides ideal assumption of the force and the spread of the chain system, the product tensile strength (> 150 mpa), adapt to all kinds of soil, is currently widely used reinforcement reinforcement material.

Product features:

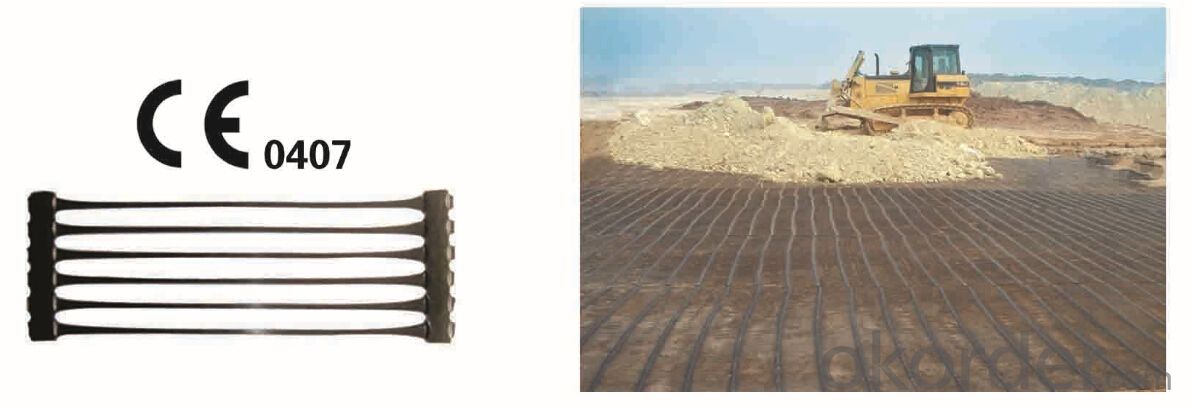

1, strengthen roadbed, can effectively allocate diffusion load, improve the stability and bearing capacity of subgrade, prolong service life.

2, can withstand greater alternating load;

3, prevent subgrade material loss caused by the embankment, cracking;

4, make the file after the wall of the filled soil bearing capacity increase, reduce the pressure of the retaining wall, save costs and prolong service life, and reduce maintenance costs;

5, spray anchor concrete construction method for slope maintenance, not only can save 30% - 50% of the investment, but also can shorten the time limit for a project more than double;

6, adding geogrid in highway roadbed and road surface, reduces the deflection, reduce furrow, delay cracking 3 to 9 times, structure layer thickness can be reduced by 36%;

7, used in a variety of soil, no need different materials, save work time;

8, easy construction, can greatly reduce the construction cost.

Product application:

1, mainly used for retaining wall, abutment, steep slope engineering, etc.;

2, retaining wall and the abutment belongs to the mechanical structure, all bear the external loads, the active earth pressure, the upper structure of the load, temperature stress, such as reinforced material under great tension for a long time, and again and again under the action of dynamic load, the molecular structure of the material to produce fatigue, its performance attenuation, accelerate the ageing of the grille, to avoid structure due to the creep in reinforcement material and produce large deformation, should choose to unidirectional geogrid of high-density polyethylene as raw material.

Product specifications:

TGDG35 TGDG50 TGDG80 TGDG110 TGDG120

- Q: Can geogrids be used in soil stabilization for airport runways?

- Yes, geogrids can be used in soil stabilization for airport runways. Geogrids are often used to reinforce and stabilize the soil, providing increased load-bearing capacity and reducing the potential for soil settlement and erosion. This makes them an effective solution for enhancing the stability and durability of airport runways, especially in areas with poor soil conditions or heavy traffic loads.

- Q: What are the factors that influence the design and selection of geogrids for reinforcement?

- The factors that influence the design and selection of geogrids for reinforcement include the type and properties of the soil, the load and traffic conditions, the desired level of reinforcement, the project lifespan, the installation and construction method, and the environmental conditions.

- Q: Anchorage length of Geogrid

- B. on the new cement concrete road surface, glass fiber grid should be placed between semi-rigid base and rigid cement concrete seal.C. on the old asphalt pavement repair, you can use the fuel injection method, anchoring method, self-adhesive method, in the original pavement laying fiberglass grille. Can also be done on the original pavement 20mm-30mm fine asphalt concrete leveling layer, and then laid fiberglass grille, and then paved asphalt concrete surface, the thickness should be 60-100mm.

- Q: What is the GDL geogrid

- GDL geogrid is uniaxial plastic geogrid, uniaxial plastic geogrid with high density polyethylene (HDPE) as raw materials, pressure into a sheet by extrusion and punching network rules, and then the longitudinal stretch into the geogrid.

- Q: Evaluation criteria and technical disclosure of geogrid.. Know how to share. Thank you

- 1) place: in the surface layer of 50cm thick sand gravel or sand (egg) gravel cushion, and compaction, which is not only conducive to improve the friction between the soil and the grid, but also conducive to the consolidation of the foundation drainage

- Q: What are the benefits of using geogrids in pavement construction?

- There are several benefits of using geogrids in pavement construction. Firstly, geogrids enhance the pavement's structural integrity by providing additional tensile strength. This helps to distribute loads more evenly, reducing the risk of cracking or rutting. Secondly, geogrids improve the pavement's durability and lifespan by resisting the effects of fatigue and aging. They can also help to reduce maintenance costs over time. Additionally, geogrids aid in preventing reflective cracking, which occurs when cracks from the underlying pavement transfer to the surface. By reinforcing the pavement layers, geogrids minimize the likelihood of reflective cracking, resulting in a smoother and safer road surface.

- Q: How much is a square meter

- 2, the use of Geogrid on the railway to avoid the soft ground on the basis of the railway premature settlement and destruction of real estate3, the geogrid used in the dam, dam, river, canal, Wai sea embankment, reservoir reinforcement and other water conservancy projects

- Q: Are geogrids cost-effective?

- Yes, geogrids can be considered cost-effective. Geogrids help to improve the stability and performance of soil structures, reducing the need for excessive amounts of expensive construction materials. They also have a longer lifespan compared to traditional methods, resulting in lower maintenance and replacement costs over time. Additionally, geogrids can enhance project efficiency by reducing construction time and labor costs.

- Q: How do geogrids improve the performance of unpaved roads?

- Geogrids improve the performance of unpaved roads by enhancing the stability and strength of the road base. They help distribute the load and prevent the lateral movement of soil particles, thereby reducing rutting and potholes. Geogrids also enhance the overall longevity of the road by reducing the need for maintenance and repair, making the road more durable and cost-effective in the long run.

- Q: How long do geogrids typically last?

- Geogrids typically have a lifespan of 20 to 50 years, depending on factors such as installation quality, environmental conditions, and the specific application they are used for.

Send your message to us

PP/HDPE One-Way Plastic Geogrids for Asphalt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords