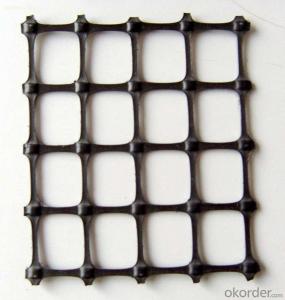

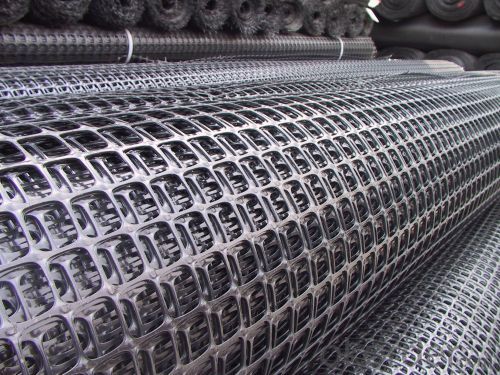

HDPE Geocells PP Plastic Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

1. high tension resistance.

2. high plane torsion resistance modulus.

3. good creep resistance and stable chemical nature.

4. high mechanic damage resistance.

5. reduce filling thickness, improve bearing capacity.

The main function as follows:

1.Reinforce the base, efficiently allot and diffuse the pressure, prolong the using time;

2.Increase the load-bearing capabilities;

3.Avoid the base becoming deformed and creaking (for the material washed away);

4.Improve the endure, reduce the pressure of the blocking wall, save the cost, prolong the using time, and reduce the servicing;

5.Reduce the crook and track, delay 3-9 times of the appearance of the crack, reduce 36% of the thickness of the structure by adding the geogrid into the base and cover of the road,

6.Be applicable of all kinds of soil;

7.Be easy to construct and reduce the cost.

Geogrid Features:

(1)High intension,high tenacity,high occlusive force with soil or gravel,erosion-resistant,

water drainage,light weigth.

(2)Reinforce soft soil roadbed,rib side slope of embankment,enhance isolation,

inhibit ground deformation,prevent crack by reflection,increase strength of roadbed.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: What are the criteria for the use of plastic geogrid

- Each grid has a variety of specifications, the specific reference to the national standard requirements, but the specifications are not necessarily the same as the national standard.

- Q: How do geogrids improve the performance of geotextile containers?

- Geogrids improve the performance of geotextile containers by providing additional strength, stability, and reinforcement to the structure. By incorporating geogrids into the design, geotextile containers become more resistant to stress, deformation, and settling. The geogrids effectively distribute loads across the container's surface, preventing excessive strain on the geotextile material and maintaining the integrity of the structure.

- Q: Is there a geogrid in the transition section of Railway

- He is mainly a connection and prevent sinking

- Q: The amount of geotextile is estimated to be used on both sides of the retaining wall

- The use of the depth is greater than geotextile, geogrid generally in the 1-2 m or deeper in the use of the scope of the geotextile in general about 50CM

- Q: Are geogrids suitable for use in bridge approaches?

- Yes, geogrids are suitable for use in bridge approaches. Geogrids are commonly used in civil engineering and construction projects to reinforce soil and provide stability. In bridge approaches, where the ground needs to bear heavy loads and prevent settlement, geogrids can effectively distribute the load and reduce the potential for soil erosion. They enhance the overall strength and durability of the bridge approach, making geogrids a suitable choice for this application.

- Q: Plastic two-way geogrid hole 4 cm thick, 1 mm wire width of 4 mm

- You say how many grams a square, or how many KN,

- Q: Can geogrids be used in ground stabilization for oil and gas facilities?

- Yes, geogrids can be used in ground stabilization for oil and gas facilities. Geogrids are highly effective in reinforcing the soil and providing stability, which is essential for supporting heavy equipment and infrastructure in these facilities. They help to prevent soil erosion, increase load-bearing capacity, and improve overall ground stability, making them a suitable solution for oil and gas facilities.

- Q: How much is a square meter

- 4, geogrid reinforced airport foundation can greatly improve the bearing capacity of the runway, to ensure the safety of aircraft landing5, geogrid can be used for garbage disposal, power plants, ash dam project, coal mine, metallurgy, green, enclosure and other fields6, the construction of soft foundation reinforcement, improve the overall bearing capacity of the foundation

- Q: Can geogrids be used in ground stabilization for wastewater treatment plants?

- Yes, geogrids can be used in ground stabilization for wastewater treatment plants. Geogrids are commonly utilized in civil engineering projects to reinforce soil and provide stability. In the case of wastewater treatment plants, geogrids can help prevent soil erosion, improve load-bearing capacity, and enhance overall ground stability, making them a suitable option for ground stabilization in such facilities.

- Q: What is the purpose of using the three - way geogrid in the gravel layer

- Reinforced with three - way geogrid

Send your message to us

HDPE Geocells PP Plastic Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords