Polyester/ Fiberglass Geogrid/ PP Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

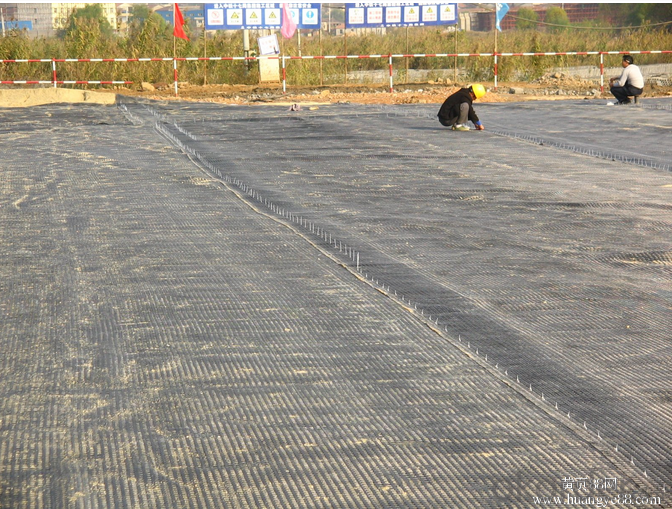

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

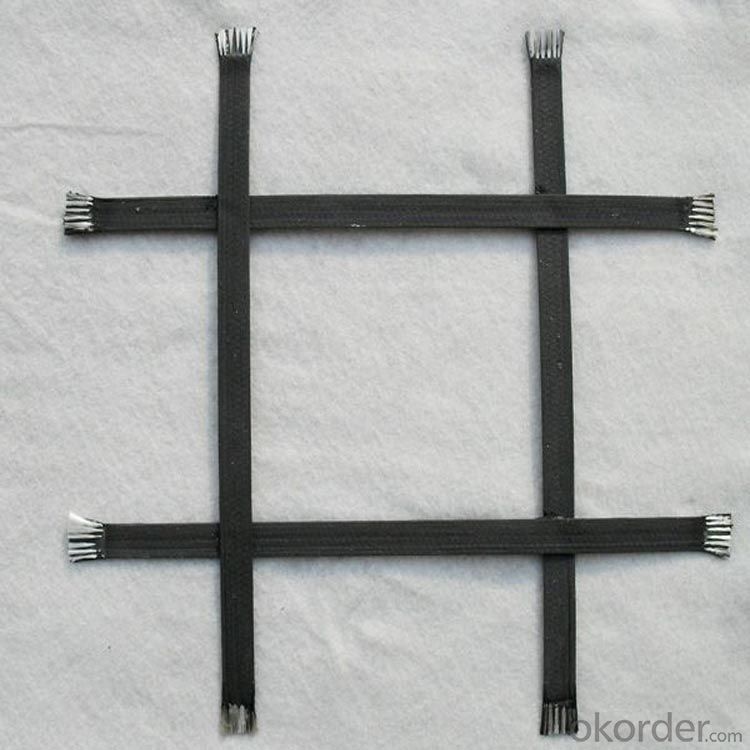

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Introduction of PP/HDPE Uniaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Features of PP/HDPE Uniaxial Geogrid:

With high tensile strength and tensile modulus

Application of PP/HDPE Uniaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

Introduction of Polyester Geogrid:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

Sarah

- Q: What is the purpose of using geotextile tubes in shoreline restoration projects?

- The purpose of using geotextile tubes in shoreline restoration projects is to provide erosion control and stabilize the shoreline. These tubes act as a barrier, preventing sediment from being washed away by waves and currents. They also help to promote the growth of vegetation by trapping sediment, creating a more stable environment for plants and marine life. Additionally, geotextile tubes can be filled with sand, creating a natural-looking shoreline that blends in with the surrounding area. Overall, geotextile tubes are a cost-effective and environmentally friendly solution for restoring and protecting shorelines.

- Q: How do geotextile tubes work in dewatering applications?

- Geotextile tubes work in dewatering applications by allowing water to be separated from sludge or sediment. The tubes are filled with the material to be dewatered, and as water passes through the permeable geotextile fabric, it is filtered out while the solid particles are retained inside the tube. The remaining sludge or sediment can then be easily disposed of, while the filtered water can be discharged or reused.

- Q: Are earthwork products resistant to pests and insects?

- Yes, earthwork products are generally resistant to pests and insects due to their natural composition and lack of organic materials that attract them.

- Q: How does erosion control matting work?

- Erosion control matting works by providing a protective layer over soil surfaces to prevent erosion caused by wind, water, or other natural forces. The matting is typically made of biodegradable materials like straw, coconut fibers, or jute and is installed on slopes or areas prone to erosion. This matting helps stabilize the soil, reduces water runoff, and promotes vegetation growth by retaining moisture and preventing soil particles from being carried away.

- Q: What are the different types of geosynthetic reinforcements for bridge abutments?

- There are several types of geosynthetic reinforcements that are commonly used for bridge abutments, including geotextiles, geogrids, and geocomposites. Geotextiles are permeable fabrics that are used to separate, filter, reinforce, and protect the soil behind the abutment. Geogrids are high-strength materials that are used to provide tensile reinforcement and improve the stability of the soil. Geocomposites, on the other hand, are a combination of geotextiles and geogrids, offering the benefits of both materials. These geosynthetic reinforcements play a crucial role in enhancing the overall performance and longevity of bridge abutments.

- Q: Are earthwork products resistant to erosion caused by wave action?

- Earthwork products are not inherently resistant to erosion caused by wave action. However, certain measures and techniques can be implemented during the construction of earthwork structures to enhance their erosion resistance. These may include incorporating erosion control materials, such as geotextiles or erosion control blankets, as well as proper grading and slope stabilization methods. Additionally, ongoing monitoring and maintenance of these structures are crucial to ensure their long-term effectiveness in withstanding wave-induced erosion.

- Q: How do geosynthetic liners help in preventing contaminant leakage?

- Geosynthetic liners are an effective solution for preventing contaminant leakage due to their impermeable nature. These liners act as a barrier, preventing the migration of pollutants and hazardous substances into the surrounding environment. By creating a sealed containment system, geosynthetic liners ensure that contaminants, such as chemicals, waste, and liquids, are securely contained, reducing the risk of contamination to soil, groundwater, and nearby ecosystems.

- Q: What are the benefits of using geosynthetic clay liners in golf course ponds?

- Geosynthetic clay liners offer several benefits when used in golf course ponds. Firstly, they provide an effective barrier against seepage and leakage, ensuring the pond retains water efficiently. Secondly, they are highly durable and can withstand harsh weather conditions, preventing erosion and maintaining the structural integrity of the pond. Additionally, geosynthetic clay liners are environmentally friendly as they reduce the need for excavation and the use of traditional clay liners, thus minimizing disruption to the surrounding ecosystem. Lastly, their installation is relatively quick and cost-effective compared to other liner options, making them a practical choice for golf course pond construction.

- Q: Are earthwork products suitable for both residential and commercial projects?

- Yes, earthwork products are suitable for both residential and commercial projects. Whether it is for landscaping, construction, or site preparation, earthwork products such as soil, gravel, and aggregates can be used in various applications for both types of projects.

- Q: Can earthwork products be used in storm surge protection?

- Yes, earthwork products can be used in storm surge protection. They can be used to build levees, berms, or dikes that help divert or absorb the impact of storm surges, reducing the risk of flooding and protecting coastal areas from the destructive forces of large waves and water inundation.

Send your message to us

Polyester/ Fiberglass Geogrid/ PP Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords