PP Staple Fiber for Non-woven Geotextile Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 4000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Specification of PP Staple Fiber for non-woven Geotextile Use

1.Material | 100% polypropylene staple fiber |

2.Color | White,etc |

3.Fineness | 2.5D-25D |

4.Fiber Length | 51mm/64mm/76mm,etc |

5.Samples Time | within 3 days if available spec |

6.MOQ | 20 Metric tons |

7.Delivery time | within 15days against T/T deposit or L/C original |

8.Packing&Container loading

| option 1: Hydraulic pressure bale, 275kg/bale. |

option 2: as customer required. | |

20GP: 1*20GP can be loaded 9Tons. | |

40HQ: 1*40HQ can be loaded with 20 Tons. | |

9.Production Capacity | 500Mtons per month |

10.Payment term | L/C at sight, T/T 50% deposit, balance against B/L. |

Features

Synthetic Polypropylene Concrete Fiber, as the filling material of concrete, has the properties of good dispersibility, resistance to acid and alkali. The main functions are:

1. crack resistance;

2. Increase the seepage resistance of concrete;

3. Increase the freezing & thawing resistance of concrete;

4. Increase the impact resistance of concrete;

5. Increase the durability resistance of cncrete;

6. Increase the fire resistance of concrete.

End use of PP Staple Fiber for non-woven Geotextile Use

stuffing and packing of toy,pillow,sofa,seatcushion and leaning cushion;

thermalinsulation lining of shoes,gloves,cap and garment and so on;

raw material of spray finishing cotton,gel-free cotton,hardening cotton and non wovens;

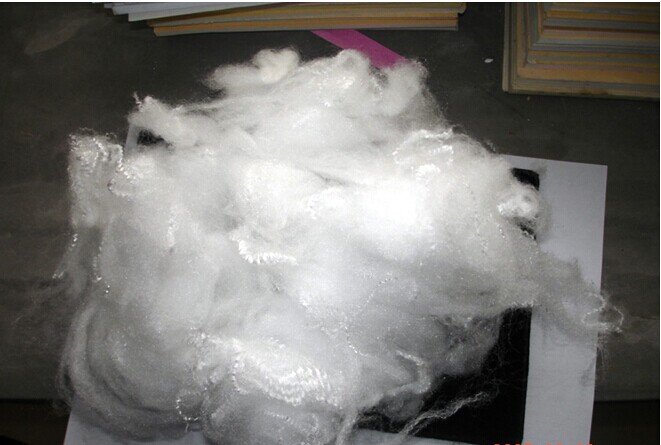

Product Photos of PP Staple Fiber for non-woven Geotextile Use

- Q: How do geosynthetic liners prevent leakage in reservoirs and ponds?

- Geosynthetic liners prevent leakage in reservoirs and ponds by providing a barrier that effectively contains and prevents the seepage of water. These liners are made of durable materials, such as high-density polyethylene (HDPE), that are resistant to punctures, tears, and chemical degradation. By placing these liners beneath the reservoir or pond, they create a reliable impermeable layer that prevents water from infiltrating into the underlying soil or escaping through the sides. Additionally, geosynthetic liners are installed with proper overlap and seaming techniques to ensure a tight and continuous seal, minimizing the risk of leakage and environmental hazards.

- Q: Can geosynthetics be used for lining fish ponds?

- Yes, geosynthetics can be used for lining fish ponds. They are commonly used as liners to prevent water seepage and create a barrier between the pond and the ground. Geosynthetics offer various benefits such as durability, flexibility, and resistance to chemicals, making them suitable for lining fish ponds and ensuring the containment of water and the protection of fish habitats.

- Q: Civil engineering and new materials, which is a good job

- The relevant companies may not be a lot, may graduate or go to the material or energy-related professional employment.

- Q: What are the advantages of using earthwork products in landscaping projects?

- There are several advantages of using earthwork products in landscaping projects. Firstly, earthwork products such as gravel, sand, and mulch provide a stable and durable base for various landscaping features such as pathways, driveways, and patios. They help to prevent erosion and maintain the integrity of the landscape. Secondly, earthwork products can enhance the aesthetics of a landscaping project. Whether it's using decorative gravel to create distinct patterns or incorporating colored mulch to add visual interest, these products can greatly enhance the overall appearance of the landscape. Additionally, earthwork products are often cost-effective and readily available. They are generally more affordable than alternative materials and easily accessible, making them a practical choice for landscaping projects. Lastly, earthwork products are versatile and can be used for various purposes. From creating retaining walls to improving drainage systems, these products offer flexibility in design and functionality, allowing for the creation of unique and functional landscapes. Overall, the advantages of using earthwork products in landscaping projects include stability, aesthetics, affordability, availability, and versatility.

- Q: Can earthwork products be used in floodplain management?

- Yes, earthwork products can be used in floodplain management. Earthwork products such as levees, berms, and floodwalls can be constructed to redirect or control floodwaters, thereby reducing the risk of flooding in floodplain areas. These products are designed to strengthen the natural landscape and help manage water flow, protecting homes, infrastructure, and ecosystems in flood-prone regions.

- Q: What are the different shapes available in earthwork products?

- There are several different shapes available in earthwork products, including but not limited to rectangular, square, circular, triangular, trapezoidal, and irregular shapes. These shapes can be customized and designed to meet specific project requirements and demands.

- Q: What are the advantages of using geotextile tubes for canal restoration?

- There are several advantages of using geotextile tubes for canal restoration. Firstly, geotextile tubes provide effective erosion control, preventing further degradation of the canal banks. Secondly, these tubes are made of permeable fabric, allowing water to pass through while retaining sediment, which helps in the natural process of sediment deposition and formation of stable canal beds. Additionally, geotextile tubes are easy to install and can be customized to fit different canal sizes and shapes, making them a versatile solution for restoration projects. Lastly, these tubes are durable, resistant to UV degradation and chemicals, ensuring long-term stability and effectiveness in restoring and maintaining canal infrastructure.

- Q: Can geosynthetics be used for reinforcement in dam construction?

- Yes, geosynthetics can be used for reinforcement in dam construction. Geosynthetics such as geotextiles, geogrids, and geomembranes offer various benefits like improved stability, increased load-bearing capacity, erosion control, and enhanced seepage control. They are commonly used to reinforce and provide additional strength to dams, ensuring their structural integrity and longevity.

- Q: What are the installation timeframes for earthwork products?

- The installation timeframes for earthwork products can vary depending on the specific project requirements and scope. It is best to consult with a professional contractor or supplier who can provide accurate estimations based on the specific earthwork products and project specifications.

- Q: What are the key considerations when using geosynthetic materials in dam construction?

- When using geosynthetic materials in dam construction, some key considerations include the type and quality of the geosynthetic material, its compatibility with the soil and other construction materials, design and installation considerations, and long-term performance and durability. It is essential to select the appropriate geosynthetic material that can withstand the specific site conditions and provide the necessary functions such as filtration, separation, reinforcement, or drainage. Compatibility with the soil and other materials is crucial to ensure proper interaction and performance. The design and installation process should be carefully planned and executed to ensure the geosynthetic materials are properly integrated into the dam structure. Finally, long-term performance and durability should be assessed to ensure the geosynthetic materials can withstand the anticipated loads, environmental conditions, and potential aging factors over the dam's lifespan.

Send your message to us

PP Staple Fiber for Non-woven Geotextile Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 4000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords