Monofilament PP Fiber for Concrete Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Monofilament PP Fiber for Concrete

PP fiber is also called engineering fiber,concrete fiber,anti-crack fiber,crack control fiber,synthetic fiber or plastic fiber,etc.It is a kind of high intensity bunchy monofilament fiber mainly made of PP by special technique

Put PP fiber into the concrete or mortar, can effectively prevent temperature change, microcrack caused by plastic and dry shrinkage,etc, thereby prevent crack and improve effectively anti-crack,anti-infiltration,anti-concussion and anti- shock of the concrete.

They are used in roads,bridges,underground waterproof projects and roofings,walls,pools,basements of the industrial civil construction

2. Specifications of Monofilament PP Fiber for Concrete

PARAMETER | UNIT | GUARANTEE VALUE |

Specific Gravity | g/cm3 | 0.91~0.93 |

Available lengths | mm | 3, 6, 10, 12, 15, 19 |

Tensile Strength | Mpa | 450 min |

Modulus of Elasticity | Mpa | 3000 min |

Melt Point | °C | 160~180 |

Heat Conductivity | - | LOW |

Water Absorption | - | NEGLIGIBLE |

3. Product Function of Monofilament PP Fiber for Concrete

1). Resist to shrink & crack;

2). Increase impact resistance and peeling resistance;

3). Increase friction resistance;

4). Increase seepage resistance;

5). Increase freezing & thawing resistance;

6). Improve tendons protection

7). Prevent mortar split and crackle expansion;

8). Replace steel net (using in plastering).

4.FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

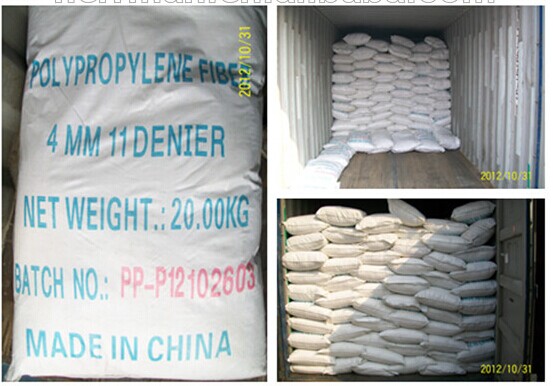

5. Product Show of Monofilament PP Fiber for Concrete

- Q:What are the main properties of the materials used in civil engineering requirements?

- Environmental protection, economy, convenience are in line with the job

- Q:Are earthwork products suitable for road verge stabilization?

- Yes, earthwork products are suitable for road verge stabilization. They can be used for various purposes such as retaining soil, preventing erosion, and providing structural support to road verges. These products, such as geotextiles, geogrids, and erosion control blankets, help to improve the stability and longevity of the road verges by reducing soil movement and promoting vegetation growth.

- Q:Can earthwork products be customized according to specific project requirements?

- Yes, earthwork products can be customized according to specific project requirements. The flexibility of earthwork materials allows for adjustments in size, shape, and composition to meet the specific needs of a project. Customization ensures that the earthwork products align with the project's specifications, enhancing efficiency and effectiveness.

- Q:What are the long-term performance benefits of earthwork products?

- The long-term performance benefits of earthwork products include improved stability and durability of structures, enhanced erosion control, increased water retention capabilities, and reduced maintenance and repair costs over time.

- Q:What are the different sizes available for earthwork products?

- The sizes available for earthwork products vary depending on the specific product. Common sizes for earthwork products include small, medium, and large, as well as specific measurements such as cubic yards or tons. It is best to consult with a supplier or manufacturer to determine the exact sizes available for the specific earthwork product needed.

- Q:What are the different applications of geogrids in road and railway construction?

- Geogrids are extensively used in road and railway construction for various applications. They are primarily utilized to enhance the stability and load-bearing capacity of the construction materials. Geogrids are used in the following areas: 1. Subgrade reinforcement: Geogrids are placed within the subgrade soil to improve its strength and prevent it from excessive settlement. They distribute the load more evenly, enhancing the stability of the road or railway. 2. Embankment reinforcement: Geogrids are employed in embankments to provide reinforcement and prevent slope failures. They help in controlling the lateral movement of soil, reducing the chances of erosion and maintaining the integrity of the embankment. 3. Base course stabilization: Geogrids are used in the base course of roads and railways to improve their strength and durability. They reduce the deformation and increase the load-bearing capacity of the base course materials, minimizing the chances of rutting and pavement failure. 4. Retaining wall reinforcement: Geogrids are employed in the construction of retaining walls to add stability and strength. They prevent the lateral movement of soil behind the wall, reducing the risk of wall failure and maintaining its structural integrity. 5. Slope stabilization: Geogrids are used to stabilize slopes and prevent erosion and landslides. They reinforce the soil structure, preventing it from sliding down the slope and ensuring its stability. Overall, geogrids play a crucial role in road and railway construction by improving the strength, stability, and longevity of the structures, enhancing their performance and reducing maintenance costs.

- Q:What is the purpose of using geocomposites in drainage systems?

- The purpose of using geocomposites in drainage systems is to enhance the efficiency and performance of the system. Geocomposites are designed to provide multiple functions such as filtration, separation, reinforcement, and drainage. They help in preventing clogging by filtering out fine particles, providing a stable base for the drainage system, and facilitating the efficient flow of water. Overall, geocomposites improve the longevity and effectiveness of drainage systems by optimizing their functionality.

- Q:How do earthwork products contribute to soil stabilization?

- Earthwork products such as geotextiles, geogrids, and geocells play a vital role in soil stabilization by providing reinforcement, erosion control, and drainage. These materials are designed to increase the shear strength of the soil, prevent soil erosion, and enhance its load-bearing capacity. By distributing the forces exerted on the soil, these products help in reducing soil settlement, improving slope stability, and preventing landslides. Additionally, they promote water drainage, preventing waterlogging and the subsequent weakening of the soil. Overall, earthwork products act as a protective layer, enhancing the stability and longevity of the soil.

- Q:What are the requirements for civil engineering materials?

- See if you are studying or working at the site

- Q:How can geotextile bags be used in riverbank protection?

- Geotextile bags can be used in riverbank protection by placing them along the riverbank to prevent erosion and stabilize the soil. These bags are filled with sand or soil and can act as a barrier, absorbing the force of the water flow and reducing its impact on the riverbank. Additionally, geotextile bags promote vegetation growth, further strengthening the bank and providing a natural defense against erosion. Overall, they are an effective and sustainable solution for riverbank protection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Monofilament PP Fiber for Concrete Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords