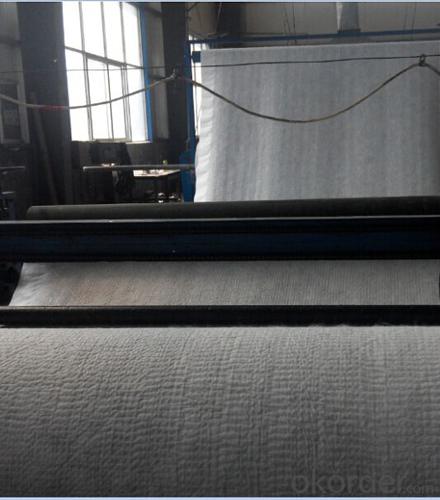

Geocomposite Geonet For Refuse Landfill

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geocomposite Geonet For Refuse Landfill

Introuduction :

geonet can be used in the soft soil stabilization, base reinforcement, embankments over soft soils, seacoast slope protection and reservoir bottom reinforcement, etc

It prevents the slope rock from falling down ,which avoids the hurt to the human beings and the vehicle on the road; It prevents the road dregs packed by geonet from being washed away ,avoids the roadbed distortion and improves the stability of the roadbed; laying the geonet reinforces the road surface ,avoids development of the reflection crack. As reinforcing material of filling soil in retaining walls, it disperses the earth body stress and restricts the side-displacement. The stone cage, made of geonet, can prevent erosion ,collapsing and lost of water and soil when being used in dyke and rock slope protetion

Application:

1) Landfill drainage;

2) roadbed and road drainage;

3) railway drainage;

4) tunnel drainage,

5) underground structure drainage,

6) the retaining back wall drainage;

7) gardens and sports ground drainage

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

Usages:

In the railway, highway and other transportation infrastructure, drainage system safety and the service life

of the project and its have inseparable relationship, in which the geotextile material is an important part

of drainage system, the drainage effect of 3D composite drainage net is particularly notable. mainly

used for tunnels, municipal engineering, reservoir, revetment in drainage engineering.

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

- Q: Why the ancient Chinese architecture to civil materials, while the use of stone in Europe it?

- Ancient China mainly lived in the northern Yellow River basin, and later gradually migrated to the south, and the Yellow River Basin and the original trees and less stone, so the majority of the main civil construction, and the European stone Hill more stone is also sufficient, many of the original is lean stone mountain Built, can be local materials, so the majority of stone construction

- Q: What are the different types of geotextile bags used for sediment control?

- There are several types of geotextile bags used for sediment control, including sediment bags, silt bags, sand bags, and erosion control bags. These bags are typically made of woven or non-woven geotextile fabric and are filled with various materials such as sand, gravel, or organic materials. They are used to trap sediment, filter water, and prevent erosion in construction sites, riverbanks, and other areas prone to sediment runoff.

- Q: How do geosynthetic products contribute to erosion control in coastal areas?

- Geosynthetic products play a crucial role in erosion control in coastal areas by providing effective solutions to stabilize and protect the shoreline. These products, such as geotextiles, geogrids, and geocells, are designed to enhance the natural resilience of coastal ecosystems while preventing land loss due to erosion. They are used in various applications like beach nourishment, dune stabilization, revetments, and breakwaters. By providing additional structural support, geosynthetics help to dissipate wave energy, reduce sediment transport, and promote sediment accretion. Overall, geosynthetic products are instrumental in maintaining the integrity of coastal areas and safeguarding them from erosion.

- Q: How are earthwork products manufactured?

- Earthwork products, such as soil, sand, and gravel, are typically manufactured through a process known as excavation. This involves using heavy machinery, like excavators and bulldozers, to remove soil and other materials from the ground. The extracted earth is then screened, crushed, and sorted to meet the desired specifications. Various quality control measures, such as moisture testing and compaction, are also implemented to ensure the products' suitability for construction and landscaping purposes.

- Q: How do earthwork products compare to traditional construction materials in terms of cost?

- Earthwork products, such as soil, gravel, and rocks, tend to be more cost-effective compared to traditional construction materials. This is primarily because earthwork materials are often readily available on-site or can be easily sourced locally, reducing transportation costs. Additionally, earthwork products can be recycled or reused, further minimizing expenses. On the other hand, traditional construction materials like concrete, steel, and lumber typically require more resources, energy, and manufacturing processes, making them relatively more expensive. However, it is important to note that the specific cost comparison may vary depending on factors such as project location, scale, and availability of materials.

- Q: Can earthwork products be used in coastal restoration projects?

- Yes, earthwork products can be used in coastal restoration projects. These products, such as sand, gravel, and soil, can be utilized to rebuild or enhance coastal areas, including beaches, dunes, and wetlands. These materials can help stabilize shorelines, protect against erosion, and create habitats for wildlife.

- Q: Can geopipes be used for drainage systems?

- Yes, geopipes can be used for drainage systems. Geopipes are commonly used in drainage applications as they provide an efficient and reliable way to collect and transport excess water from various surfaces or areas. The geopipes are designed to have high flow capacity and resist clogging, making them suitable for use in drainage systems for both residential and commercial purposes.

- Q: How do earthwork products differ from other construction materials?

- Earthwork products differ from other construction materials in that they are derived directly from the earth itself. Unlike materials such as steel, concrete, or wood, earthwork products are typically made from natural materials like soil, gravel, or sand. These products are often used in civil engineering and construction projects to create embankments, foundations, or to backfill trenches. Earthwork products are cost-effective, abundant, and can be easily sourced on-site, making them a sustainable and environmentally friendly choice for construction projects.

- Q: Are earthwork products suitable for use in railway track construction?

- Yes, earthwork products are suitable for use in railway track construction. These products, such as aggregates, ballast, and embankments, provide stability and support to the tracks, ensuring safe and efficient train operations. Additionally, earthwork materials are cost-effective, readily available, and can be easily sourced locally, making them a viable option for railway track construction projects.

- Q: Are earthwork products resistant to seismic activity?

- Earthwork products, such as retaining walls and embankments, can be designed to withstand seismic activity. By incorporating proper engineering techniques and reinforcement, these structures can be made resistant to the effects of earthquakes. However, it is crucial to consider the specific location, soil conditions, and design requirements to ensure optimal seismic resistance.

Send your message to us

Geocomposite Geonet For Refuse Landfill

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords