Geocomposite Drain Installation

Geocomposite Drain Installation Related Searches

Geocomposite Drain Geocomposite Wall Drain Geocomposite Subsoil Drain Geocomposite Drainage System Geocomposite Drain Strips Geocomposite Strip Drain Geocomposite Drainage Layer Geocomposite Drainage Material Geocomposite Drainage Net Geocomposite Drainage Strip Geocomposite Sheet Drain Geocomposite Drainage Board Geocomposite Drainage Mat Geocomposite Drainage Sheet Geocomposite Drainage Layer Cost Geocomposite Geocomposite Liner Geocomposite Membrane Geogrid Installation Geomembrane Drainage Geocomposite Clay Liner Gse Geocomposite Composite Geomembrane Composite Geogrid Machine Geogrid Driveway Installation Composite Geogrid Geocomposite Definition Drainage Fittings Skaps Geocomposite Geomembrane Liner InstallersGeocomposite Drain Installation Supplier & Manufacturer from China

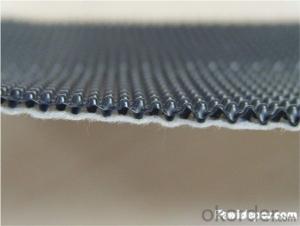

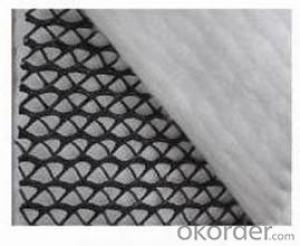

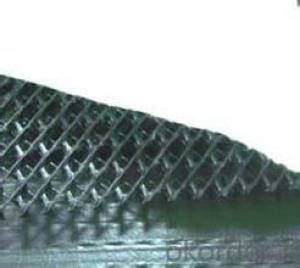

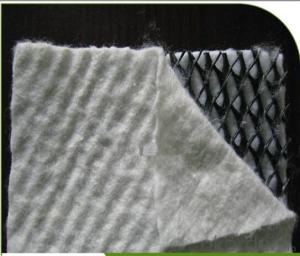

Geocomposite Drain Installation refers to the process of installing geocomposite materials in drainage systems. These products are engineered to provide efficient drainage solutions in various applications, including civil engineering, construction, and landscaping projects. Geocomposite materials are designed to facilitate the flow of water while maintaining structural integrity, making them ideal for use in areas prone to water accumulation or where water management is a concern.The application and usage scenarios for Geocomposite Drain Installation are diverse, ranging from highway and railway subgrades to retaining walls and slope protection. They are also commonly used in landfills, tunnels, and other areas where water management is crucial. These products help to reduce the risk of soil erosion, improve load-bearing capacity, and enhance the overall stability of the construction site. By effectively managing water flow, geocomposite drains contribute to the longevity and safety of infrastructure projects.

Okorder.com is a wholesale supplier of Geocomposite Drain Installation products, offering a large inventory to meet the needs of various projects. With a commitment to quality and customer satisfaction, Okorder.com ensures that the geocomposite materials they provide are of the highest standard, suitable for a wide range of applications. By partnering with Okorder.com, customers can access a reliable source for geocomposite drain installation products, ensuring that their projects are equipped with the necessary components for efficient water management and structural support.

Hot Products