Geocomposite Drainage Layer

Geocomposite Drainage Layer Related Searches

Geocomposite Drainage System Geocomposite Drainage Material Geocomposite Drain Geocomposite Drainage Net Geocomposite Drainage Strip Geocomposite Drainage Mat Geocomposite Wall Drain Geocomposite Drainage Board Geocomposite Drainage Layer Cost Geocomposite Subsoil Drain Geocomposite Drain Installation Geocomposite Drainage Sheet Geocomposite Drain Strips Geocomposite Strip Drain Geocomposite Sheet Drain Geocomposite Liner Geocomposite Geocomposite Membrane Geocomposite Clay Liner Geomembrane Drainage Composite Geomembrane Gse Geocomposite Composite Geogrid Composite Geogrid Machine Skaps Geocomposite Geomembrane Landfill Drainage Fittings Conductive Geomembrane Landfill Geomembrane Agru GeocompositeGeocomposite Drainage Layer Supplier & Manufacturer from China

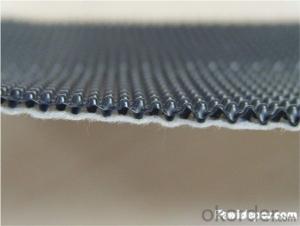

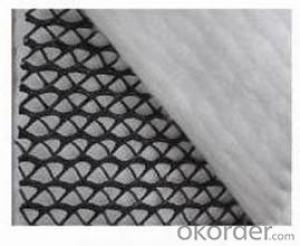

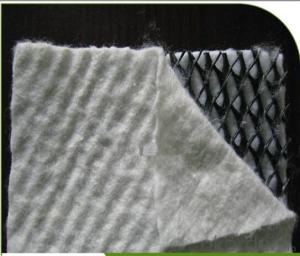

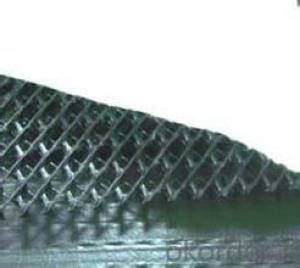

Geocomposite Drainage Layer is a specialized product that consists of a combination of geotextiles and drainage cores, designed to manage water flow and provide filtration in various construction projects. This innovative material is widely used in civil engineering and landscaping applications, such as road construction, slope stabilization, and water retention systems. The product's unique design allows for efficient water drainage while preventing soil particles from clogging the drainage channels, ensuring optimal performance and longevity.In various application and usage scenarios, the Geocomposite Drainage Layer plays a crucial role in maintaining the structural integrity and stability of the project. It is particularly effective in situations where water management is a critical concern, such as in areas prone to flooding or with poor soil drainage. By providing a reliable and efficient drainage solution, this product helps to prevent water-related damage and ensures the long-term stability of the construction. The Geocomposite Drainage Layer is also an environmentally friendly option, as it promotes sustainable water management practices and reduces the environmental impact of construction projects.

Okorder.com is a reputable wholesale supplier of Geocomposite Drainage Layer, boasting a large inventory of this high-quality product. With a commitment to providing excellent customer service and competitive pricing, Okorder.com is the ideal choice for businesses and contractors seeking to purchase this essential material in bulk. By offering a wide range of options and sizes, Okorder.com ensures that customers can find the perfect Geocomposite Drainage Layer to meet their specific project requirements.

Hot Products