Cow Carpet Geotextile Geocomposite Drain for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geocomposite Drain for Road Railway Highway Tunnel

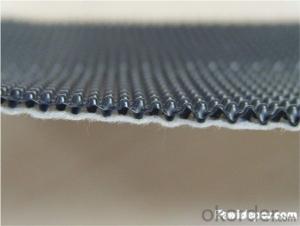

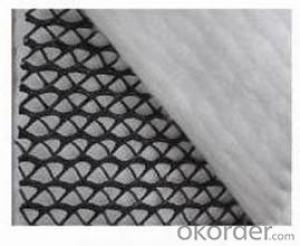

Geocomposite drain is made of fiber extruded from thermoplastic synthetic resin. It is a tri-dimen-sional material with many holes. There is a geotextile layer outside the geocomposite drain, whose main function is to sieve sand and clay so as to avoid blockage. This product has four shapes, but mmany types, including rectangular with many holes, round shape with many holes, round shape but hollow ones.

Specification of Geocomposite Drain for Road Railway Highway Tunnel

Circular shape size D50, D70, D80, Rectangle 70X30, 120X35, 300X35, 400X35.

Property of Geocomposite Drain for Road Railway Highway Tunnel

High pressure resistance, high opening rate in surface, excellent in collecting and draining water, permanent lifetime, easy for construction, good flexibility and adaptable to the earth distortion.

Application of Geocomposite Drain for Road Railway Highway Tunnel

Drainage for tunnel, roadbed and road shoulder of highway, railway, soft bed disposal, remaining wall filtration, underground building d rainage and anti-tidal air, also water collecting and draining in green field, roof garden, sewage disposal, garbage bu rying field and other works.

- Q: What are the specifications for geotextiles in roadways?

- Geotextiles used in roadways should meet certain specifications to ensure their effectiveness. These specifications typically include factors such as tensile strength, puncture resistance, filtration capability, and elongation properties. Additionally, the geotextiles should have appropriate thickness, weight, and permeability to allow for proper drainage and filtration of water. The specifications may vary based on the specific requirements of the road project, but overall, geotextiles in roadways need to be durable, efficient, and capable of enhancing the overall performance and longevity of the road.

- Q: Are geotextiles resistant to fire damage?

- Yes, geotextiles can be resistant to fire damage. They are often manufactured to have fire-resistant properties, making them suitable for various applications where fire safety is a concern. However, it is important to check the specific type and specifications of geotextiles being used, as not all may possess the same level of fire resistance.

- Q: Can geotextiles be used in landfill construction?

- Yes, geotextiles can be used in landfill construction. They are commonly used as liners, covers, and drainage materials in landfills to prevent soil erosion, control water flow, and improve stability and performance of the landfill structure.

- Q: What are the durability considerations for geotextiles?

- Durability considerations for geotextiles include factors such as tensile strength, resistance to ultraviolet (UV) degradation, chemical resistance, and abrasion resistance. Geotextiles should have sufficient tensile strength to withstand the stresses and strains imposed on them during installation and the lifespan of the project. UV degradation can weaken geotextiles over time, so it is important to choose products with appropriate UV resistance. Chemical resistance ensures that geotextiles remain intact and functional in the presence of chemicals or contaminants in the soil or water. Additionally, geotextiles should be resistant to abrasion to withstand any potential friction or rubbing against other materials or objects.

- Q: What are the factors to consider when selecting geotextiles for a project?

- When selecting geotextiles for a project, there are several factors that need to be considered. These factors include the type and purpose of the project, the required strength and durability of the geotextile, the site conditions and environmental factors, as well as the cost and availability of the geotextiles. Additionally, factors such as installation methods, compatibility with other materials and long-term performance should also be taken into account. Overall, a thorough understanding of the project requirements and careful evaluation of these factors will help in selecting the most suitable geotextiles for the project.

- Q: Are geotextiles poisonous?

- Geotextile is not toxic, the production of geotextile raw materials are polyester (PET) or polypropylene (PP). Polyester and polypropylene have become daily necessities. Many of the mineral water bottles are also produced by PET and PP raw materials.

- Q: Geotextile and non-woven fabrics What is the difference

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: Are geotextiles suitable for use in erosion control mats for revegetation?

- Yes, geotextiles are suitable for use in erosion control mats for revegetation. Geotextiles are designed to stabilize soil and prevent erosion by providing a barrier against water and wind. They also promote vegetation growth by allowing water and nutrients to penetrate the soil while protecting the roots from erosion. Overall, geotextiles can be an effective solution for erosion control in revegetation projects.

- Q: Do you want to put the geotextile and the impounded vegetables in the soil?

- No poison, you can rest assured that use. Geotextile raw materials are PET or PP, and the production of mineral water bottles of raw materials the same, without any side effects. Water storage board is the raw material is HDPE plastic. There is no harm to people. Geotextile and water storage board is mainly used in the roof garden or underground garage roof green. It is possible to store rainwater and protect the concrete at constant temperature. , Has been widely used in developed countries. At present the country is developing urban sponge project, the application of water storage board will be more extensive.

Send your message to us

Cow Carpet Geotextile Geocomposite Drain for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords