Geocomposite Drainage System

Geocomposite Drainage System Related Searches

Geocomposite Drainage Sheet Geocomposite Drainage System Geocomposite Wall Drain Geogrid On Slope Geocomposite Drainage Mat Geocomposite Strip Drain Geocomposite Drainage Net Geocomposite Membrane Geocomposite Drainage Layer Geogrid SlopeHot Searches

Inverter Size For Solar System Bike Gps System Price In India Inverter Solar System Price Ceiling Fan Lowest Price Aluminum Channel Stock Sizes Steel Mesh Panels For Sale Cheap High Tea Sets For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale 1/4 Aluminum Plate For Sale H4 Led Headlight Bulbs For SaleGeocomposite Drainage System Supplier & Manufacturer from China

Okorder.com is a professional Geocomposite Drainage System supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geocomposite Drainage System firm in China.Hot Products

FAQ

- The purpose of using geotextiles in subgrade improvement is to enhance the stability and strength of the subgrade by providing reinforcement, separation, and filtration. Geotextiles help prevent the mixing of different soil layers, control soil erosion, and improve overall performance of the subgrade by distributing loads more evenly.

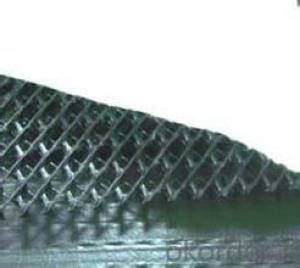

- There are several advantages of using geosynthetic materials in road pavement rehabilitation. Firstly, geosynthetics can enhance the structural integrity of the pavement by providing additional strength and stability. They can act as reinforcement layers, improving the load-bearing capacity of the road and reducing the risk of pavement failure. Secondly, geosynthetics can help in minimizing cracking and rutting in the pavement. They have excellent tensile strength, which allows them to distribute stresses and strains caused by traffic loading, preventing the formation of cracks and ruts. This leads to a longer lifespan for the road and reduces the need for frequent repairs. Another advantage is that geosynthetics can improve drainage within the pavement system. They can act as a drainage layer, facilitating the flow of water away from the road surface. This helps in preventing water accumulation, which can cause damage to the pavement structure over time. Furthermore, geosynthetics provide a cost-effective solution for road pavement rehabilitation. They are lightweight and easy to install, resulting in reduced construction time and labor costs. Additionally, their durability and longevity contribute to long-term savings as they decrease the need for frequent maintenance and repairs. Overall, the use of geosynthetic materials in road pavement rehabilitation offers numerous advantages, including increased strength, reduced cracking and rutting, improved drainage, and cost-effectiveness.

- Yes, geosynthetics can be used for lining hydraulic fracking ponds. Geosynthetics, such as geomembranes, are often used to provide a barrier between the pond and the surrounding environment. They can effectively prevent the seepage of fluids, contaminants, and chemicals, ensuring the protection of groundwater and soil. Geosynthetics also offer durability, flexibility, and resistance to punctures, making them suitable for the demanding conditions of hydraulic fracking operations.

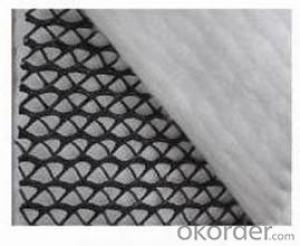

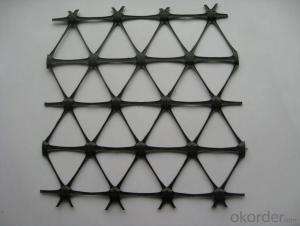

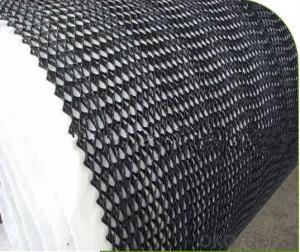

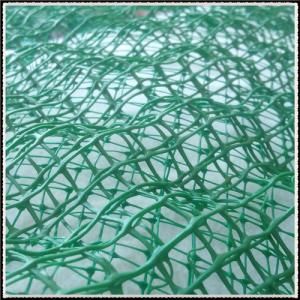

- There are several types of geosynthetic reinforcements that can be used for bridge piers. These include geotextiles, geogrids, and geocomposites. Geotextiles are permeable fabrics made from synthetic materials that provide filtration, separation, and reinforcement. Geogrids are typically made from high-strength polymers and are used to provide soil stabilization and load transfer. Geocomposites, on the other hand, are multi-component materials that combine different geosynthetic products to offer a combination of functions such as reinforcement, filtration, and drainage. These geosynthetic reinforcements help enhance the stability and performance of bridge piers by improving soil strength, reducing settlement, and protecting against erosion.

- In addition to cement, but also add gelling agent

- The role of adding gelling agent in cement mortar is to enhance the adhesion

- Geotextile mattresses are used in earthwork to stabilize and protect slopes, riverbanks, and shorelines. They are typically placed on the surface to prevent erosion by trapping soil particles while allowing water to pass through. These mattresses provide an effective solution for erosion control and can be easily installed and maintained.

- Using geomembranes for floating covers in reservoirs provides several benefits. Firstly, geomembranes act as a barrier, preventing water contamination and evaporation. This helps to maintain water quality and conserve water resources. Secondly, geomembranes are highly durable and resistant to UV radiation, chemicals, and weathering. This ensures long-term protection and reduces the need for frequent maintenance or replacement. Additionally, floating covers made of geomembranes can reduce algae growth and the formation of harmful bacteria, thus improving the overall water quality. Moreover, these covers minimize the exposure of stored water to air, reducing the risk of odor and taste issues. They also prevent the entry of debris, leaves, and other pollutants into the reservoir. Furthermore, the use of geomembranes for floating covers helps to regulate water temperature, preventing excessive heat or cold, which can be harmful to aquatic life. Overall, utilizing geomembranes for floating covers in reservoirs offers a cost-effective and efficient solution to preserve water quality, minimize evaporation, and protect the environment.

- Geosynthetic reinforcement offers several benefits for soil stabilization. Firstly, it enhances the strength and load-bearing capacity of the soil, allowing it to withstand heavy loads and prevent settlement. Secondly, it improves the overall stability of the soil, reducing the risk of erosion and slope failure. Additionally, geosynthetic reinforcement can be easily installed, saving time and labor costs compared to traditional stabilization methods. It is also a cost-effective solution as it requires less excavation and can be reused in other projects. Finally, geosynthetics offer long-term durability and resistance to environmental factors, ensuring a sustainable and reliable soil stabilization solution.