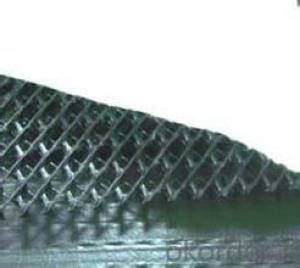

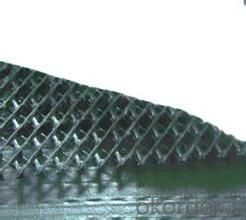

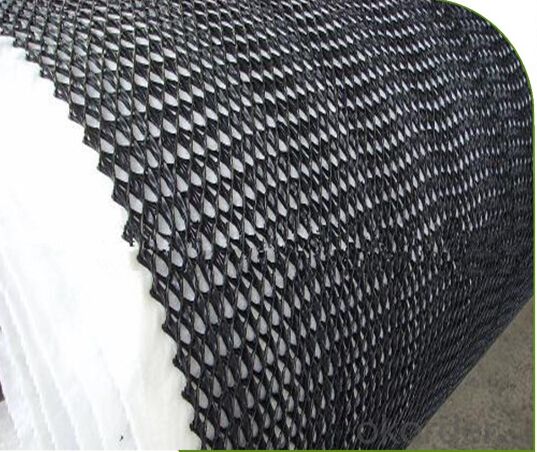

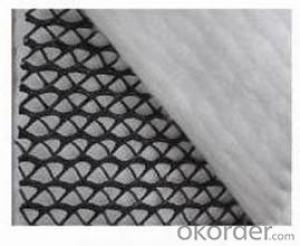

Tri HDPE Geocomposite Drainage for Slope Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tri HDPE Geocomposite Drainage for Slope Protection

Description :

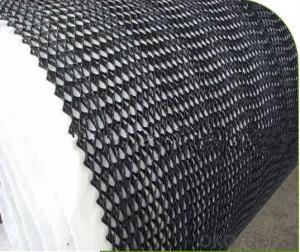

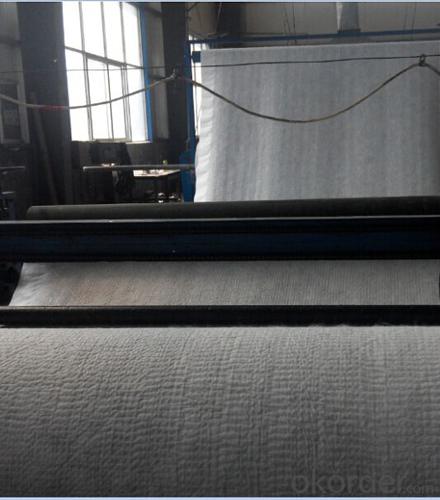

for drainage is made of a unique trmension geonet adhibited geotextile on both sides.it has the property of geotextile(filtration function ) and geonet (drainage and protection ) and provide a function system"filtration-drainage-protection".the core of net with its unique tr-dimension structure can bear higher compressing load in construction and remain the certain thickness,

provide good water conductivity.

This structure provides for high flow rates for the life of a drainage structure, not just for few hours. Therefore TENAX TENDRAIN are triplanar geocomposites engineered for long term drainage in waste containment application characterized by the following features:

Ability of the drainage structure to maintain high long term in-plane flow;

Ability of the drainage structure to withstand long term compressive loads;

Ability of the drainage structure to provide adequate shear stability.

Application:

1) Landfill drainage;

2) roadbed and road drainage;

3) railway drainage;

4) tunnel drainage,

5) underground structure drainage,

6) the retaining back wall drainage;

7) gardens and sports ground drainage

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

Usages:

In the railway, highway and other transportation infrastructure, drainage system safety and the service life

of the project and its have inseparable relationship, in which the geotextile material is an important part

of drainage system, the drainage effect of 3D composite drainage net is particularly notable. mainly

used for tunnels, municipal engineering, reservoir, revetment in drainage engineering.

FAQ

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q: Can geotextile tubes be used for shoreline protection?

- Yes, geotextile tubes can be used for shoreline protection. Geotextile tubes are often used as a cost-effective and environmentally friendly solution to prevent erosion and protect shorelines from wave action and sediment displacement. They are filled with sand or other suitable materials and placed along the shoreline to create a barrier against erosion, stabilize the coastline, and maintain the natural balance of sediment.

- Q: Can geomembranes be used for secondary containment?

- Yes, geomembranes can be used for secondary containment. They are impermeable barriers that can effectively contain and prevent the escape of liquids or hazardous materials. Geomembranes are commonly used in various industries, such as oil and gas, chemical, and waste management, to provide an additional layer of protection against potential leaks or spills.

- Q: What are the benefits of using geotextile tubes in environmental dredging?

- Geotextile tubes offer several benefits in environmental dredging. Firstly, they provide effective containment and dewatering solutions, allowing for the separation of water and solids during the dredging process. This helps in reducing the volume of material to be disposed of and minimizing the environmental impact. Secondly, geotextile tubes are cost-effective compared to traditional dewatering methods. They require less labor and equipment, resulting in lower project costs. Furthermore, the use of geotextile tubes facilitates the reuse of clean water, as it can be separated and discharged back into the environment. This is beneficial in conserving water resources and minimizing the need for additional water supply. Lastly, geotextile tubes are versatile and can be used in various dredging projects, including shoreline restoration, environmental remediation, and sediment removal. Their flexibility and adaptability make them a valuable tool in achieving sustainable and eco-friendly dredging practices.

- Q: What are the different types of geotextile fabric properties?

- Some of the different types of geotextile fabric properties include filtration, separation, reinforcement, erosion control, and drainage.

- Q: Civil engineering materials, the material strength and brittleness to enhance the plastic reduction method

- Reinforcing steel cold (cold drawing, cold drawing), can improve the strength and brittleness; plasticity.

- Q: Are earthwork products suitable for use in wetland restoration?

- Yes, earthwork products can be suitable for use in wetland restoration. These products, such as soil, sediment, or fill materials, can be used to reshape wetland landscapes, create specific hydrological conditions, or enhance habitat features. However, proper consideration must be given to the source and quality of the materials, to ensure they are free from contaminants and meet the specific needs of the wetland ecosystem being restored. Additionally, the use of earthwork products should be accompanied by careful planning, monitoring, and adaptive management to minimize potential impacts on the wetland and ensure successful restoration outcomes.

- Q: How do geopipes help in onsite sewage disposal systems?

- Geopipes play a crucial role in onsite sewage disposal systems by efficiently collecting and transporting wastewater from houses or buildings to the septic tanks or treatment areas. These specially designed pipes are perforated, allowing for the drainage of liquid waste while preventing solids from entering. Geopipes also help in distributing the effluent evenly throughout the drain field, promoting proper filtration and treatment of the wastewater before it seeps into the soil.

- Q: How do culverts contribute to earthwork projects?

- Culverts contribute to earthwork projects by providing a means for water to flow under roads, railways, or other structures, preventing erosion and maintaining the integrity of the earthwork. They help control and direct the flow of water, reducing the risk of flooding and damage to the surrounding environment. Additionally, culverts aid in the efficient drainage of water, ensuring the stability and durability of the earthwork by preventing water accumulation.

- Q: What are the advantages of using geosynthetic materials in canal lining projects?

- There are several advantages to using geosynthetic materials in canal lining projects. Firstly, geosynthetics provide excellent resistance to erosion and chemical degradation, ensuring long-term durability of the canal lining. Secondly, these materials offer superior hydraulic performance, allowing for efficient water flow and reduced seepage. Additionally, geosynthetics are lightweight and easy to install, saving time and labor costs during construction. Lastly, these materials are highly flexible and adaptable, making them suitable for various project conditions and allowing for effective reinforcement and stabilization of the canal lining.

- Q: What are the benefits of using geogrids in earthwork applications?

- Using geogrids in earthwork applications offers several benefits. Firstly, geogrids enhance the stability and strength of the soil, providing increased load-bearing capacity. This allows for the construction of structures on weak or unstable soils that would otherwise be problematic. Secondly, geogrids help to prevent soil erosion by reinforcing the soil and reducing the potential for soil movement. This is particularly beneficial in areas prone to heavy rainfall or steep slopes. Additionally, geogrids can reduce construction time and costs by minimizing the need for extensive excavation and soil replacement. Overall, incorporating geogrids in earthwork applications can improve the overall performance and longevity of the project while also providing cost and time savings.

Send your message to us

Tri HDPE Geocomposite Drainage for Slope Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords