GCL Sodium Bentonite Liner Geosynthetic Clay Liners

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GCL Sodium Bentonite Liner Geosynthetic Clay Liners

Product Introduction

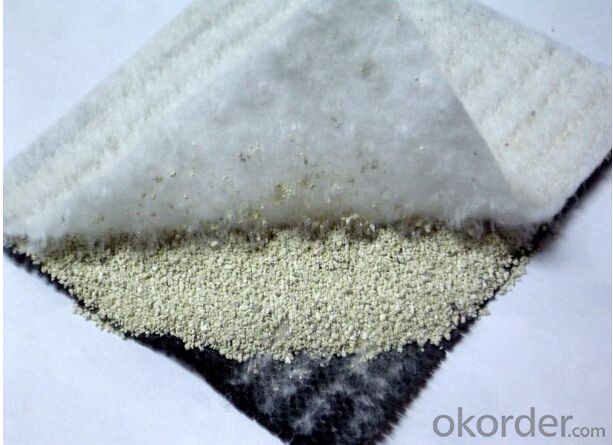

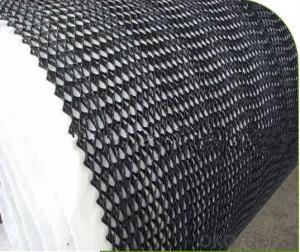

Geosynthetic clay liner is composed of high dilatability of sodium base bentonite filling between the special composite geotextile

and nonwoven fabric, made by the method of acupuncture or suture composite impervious material. Use acupuncture into

geosynthetic clay liner can form many small fiber space, make the bentonite particles can't flow in one direction, when under the

influence of water within the mat forming uniform density of colloidal waterproof layer, prevent the leakage of water.

For different projects,it can combine HDPE liner for better waterproof.

Bentonite has the expansion of the water characteristics. General calcium base bentonite expands, its expansion is only about 3 times

their own size; And sodium base bentonite adsorption 5 times its own weight of water in case of water, Volume expansion to the

original 15 to 17 times above; Lock sodium base bentonite in the middle of the two layers of geosynthetic materials, protecting

and strengthening the role of, Make the GCL has a certain overall shear strength.

GCL Feature:

1.The permanent waterproof

Because sodium base bentonite is a natural inorganic material, even after a long time or the surrounding environment changes,

also won't happen aging or corrosion phenomena, so the waterproof performance persistence.

2. Compactibility

Sodium base bentonite under water pressure condition to form diaphragm with high density, thickness of about 3 mm,

its permeability is 5 x 10-11 m/SEC below, equivalent to 100 times the compactness of 30 cm thickness of clay,

have very strong since the water retention performance.

3.Not affected by temperature

In cold climates will not brittle fracture.

4.Environmental protection

Bentonite as natural inorganic material, non-toxic harmless to human body, no special effects to the environment,

have good environmental performance.

5.Simple and short time of construction

Compared to other waterproofing materials, construction is relatively simple, don't need to be heated and paste.

With bentonite powder and nails, washers, etc are connected and fixed. After construction does not need special

inspection, if it is found that the waterproof defects and easy to maintenance.

GCL is existing waterproof material in construction period of the shortest.

Specifications

| Property | National standard | Enterprise Standard | Inspection standards |

| JG/T 193-2006 | |||

| Geosynthetic Clay Expansion index | ≥24 ml/2g | ≥25ml/2g | ASTM D5890 |

| Mass Per Unit Area(g/m2) | ≥4000 g/m2 | ≥4000 gm2 | ASTM D5993 |

| Tensile Strength | ≥6KN/m | ≥8KN/m | ASTM 4632 |

| Maximum load elongation | ≥10% | ≥10% | ASTM 4632 |

| Permeability | ≤5×10-11 | ≤5×10-11 | ASTM D5084 |

| Moisture content | ≤15% | ≤15% | ASTM D4643 |

| Peel strength | ≥40N | ≥65N | ASTM D4632 |

| Hydrostatic pressure | 0.4Mp | 0.4~0.6Mp | ASTM D5891 |

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: How can geosynthetic panels be used in dam rehabilitation projects?

- Geosynthetic panels can be used in dam rehabilitation projects for various purposes, such as erosion control, slope protection, and seepage control. These panels are placed on the surface of the dam or along its slopes to prevent soil erosion and stabilize the structure. They also help in reducing water infiltration and controlling seepage, thus improving the overall performance and safety of the dam. Additionally, geosynthetic panels can be used to reinforce weak areas of the dam, enhancing its strength and stability.

- Q: On the inorganic non-metallic materials engineering (civil materials) jobs and treatment, there are friends in this area want to introduce.

- This unit seems not stable, very big liquidity, not with the Project run may be better. Treatment are almost it, the general level.

- Q: What are the benefits of using geotextile mats in geotechnical engineering projects?

- Geotextile mats offer several benefits in geotechnical engineering projects. Firstly, they provide effective soil stabilization by preventing erosion and soil movement, thereby enhancing the overall stability of the project. Secondly, geotextile mats act as a filtration barrier, allowing water to pass through while retaining fine particles and preventing clogging of drainage systems. Additionally, these mats are cost-effective alternatives to traditional methods, reducing construction time and labor costs. Moreover, they promote environmental sustainability by minimizing the need for excavation and reducing soil loss. Overall, geotextile mats are valuable tools in geotechnical engineering, improving project durability, efficiency, and minimizing environmental impact.

- Q: Can earthwork products be used in stormwater filtration systems?

- Yes, earthwork products can be used in stormwater filtration systems. Earthwork products such as geotextiles, geogrids, and permeable pavers can help to filter and remove pollutants from stormwater runoff, improving water quality and reducing the impact on natural ecosystems. These products are designed to facilitate the filtration process by allowing water to pass through while trapping sediments, debris, and contaminants.

- Q: Are building materials the same as civil engineering materials?

- Civil engineering includes a wide range of materials, except for buildings, roads, bridges, tunnels and geotechnical materials that are related to civil engineering materials, but many of these materials are not used in industrial and civil construction.

- Q: Can earthwork products be used in stormwater detention systems?

- Yes, earthwork products such as geotextiles, geogrids, and erosion control blankets can be used in stormwater detention systems. These products help with soil stabilization, erosion control, and filtration, ensuring the proper functioning and effectiveness of the stormwater detention system.

- Q: How are geosynthetic materials used in coastal protection structures?

- Geosynthetic materials are commonly used in coastal protection structures for various purposes. They are employed to stabilize shorelines, control erosion, and provide structural support to prevent coastal land loss. Geotextiles, for instance, are often used as an underlay for coastal revetments or seawalls, enhancing their stability and preventing soil erosion. Additionally, geotubes, which are large geosynthetic containers filled with sand, can be deployed as breakwaters or dune reinforcements, effectively absorbing wave energy and protecting vulnerable coastal areas. Overall, geosynthetic materials play a crucial role in coastal protection by providing cost-effective and sustainable solutions for shoreline stabilization and erosion control.

- Q: What is the purpose of using geocells in highway shoulder stabilization projects?

- The purpose of using geocells in highway shoulder stabilization projects is to provide structural support and reinforcement to the soil, preventing erosion, and maintaining the integrity of the shoulder.

- Q: How are gabion baskets used in earthwork applications?

- Gabion baskets are widely used in earthwork applications as a versatile and effective solution for erosion control, slope stabilization, and retaining walls. These wire mesh baskets, filled with rocks or other suitable materials, provide a stable and permeable structure that can withstand water pressure, prevent soil erosion, and manage drainage. They are commonly utilized along riverbanks, highways, and construction sites to protect against soil movement, create retaining walls, and enhance overall stability in various earthwork projects.

- Q: Can earthwork products be used in geotechnical engineering applications?

- Yes, earthwork products can be used in geotechnical engineering applications. Earthwork products such as soil, gravel, and rocks are commonly used in various geotechnical engineering projects, including road construction, foundation design, slope stabilization, and retaining wall construction. These materials are often utilized to improve soil properties, provide stability, and enhance the overall performance of geotechnical structures.

Send your message to us

GCL Sodium Bentonite Liner Geosynthetic Clay Liners

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords