Geosynthetic Clay Liner(GCL) for Anti-seepage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

sodium Bentonite Geosynthetic Clay Liner(GCL) for anti-seepage

1,Introduction

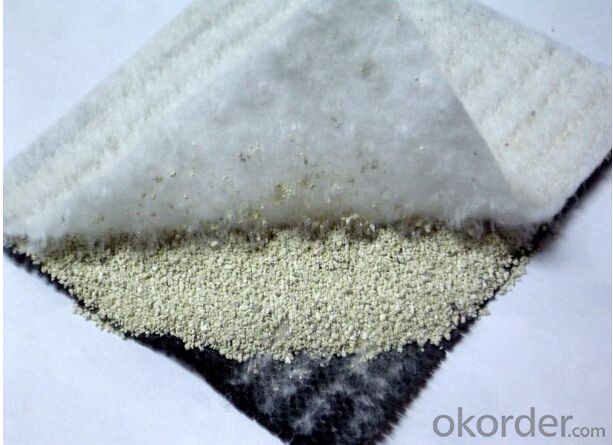

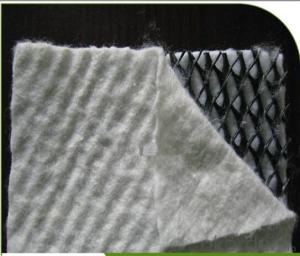

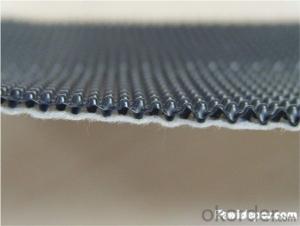

GCL is a new geosynthetics. It is graded by a natural sodium bentonite particles and corresponding additive mixed together, By special technology and equipment, the bentonite particles between two layers of geotextile fixed, made of waterproof blanket, with all the characteristics of both the geotextile material, but also has excellent water (infiltration) performance.

2,Feature

(1) A permanent waterproof performance, and excellent water seepage performance, impermeability hydrostatic pressure up to 1.0MPa above, permeability coefficient 5 *10-9cm / s. Because the Department of Natural sodium bentonite inorganic materials, even after a long time or the surrounding environment changes, aging or corrosion does not occur.

(2) Has all the characteristics of geotextile material, such as separation, reinforcement, protection, filtration, simple construction and unrestricted construction environment temperature below 0 0 C also be construction. Just when construction GCL waterproof blanket tile on the floor, when the elevation or slope construction, with nails and washers to secure it, as required, can overlap.

(3) Easy to repair; Even after water (seepage) end of construction, such as waterproof layer accident damage, as long as the site of the damage to be a simple fix, can ever regain perfect waterproof performance.

(4)green: Bentonite is a natural inorganic material, harmless, non-toxic, no particular impact on the environment, with good environmental performance.

(5) simple construction period is short: and other waterproof materials, the construction is relatively simple, does not require heating and paste. Product width up to 6 meters, with international geotextile (film) to match the size, greatly improving the efficiency of construction.

(6) Integrated waterproof materials and objects: When sodium bentonite water, with 20-28 times the capacity expansion, even if the concrete structure vibration and settlement, bentonite GCL can repair cracks in the concrete surface less than 2mm.

3,Application

(1)Municipal engineering, underground engineering subways, buildings and roofs reservoir seepage.

(2)Environmental sanitation, solid waste landfills, sewage treatment plants, industrial waste.

(3)water, rivers, lakes and reservoirs dam seepage, plugging, reinforcement.

(4)Garden artificial lake golf course pond seepage and so on.

(5)Petrochemical, mining and other areas of engineering seepage, leakage, etc.

4,Specification of Geosynthetic Clay Liner(GCL) for anti-seepage

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: How can geosynthetic panels be used in dam rehabilitation projects?

- Geosynthetic panels can be used in dam rehabilitation projects as a cost-effective and efficient solution for reinforcing and stabilizing the dam structure. These panels are often installed as a lining system on the upstream face of the dam to improve its resistance to seepage and erosion. Additionally, they can be used to reduce the potential for internal erosion and piping within the dam by providing a barrier against water flow. By integrating geosynthetic panels into dam rehabilitation projects, the overall safety and performance of the dam can be significantly enhanced.

- Q: How do earthwork products help with sediment control?

- Earthwork products help with sediment control by providing physical barriers and erosion control measures to prevent soil erosion and sediment runoff. These products, such as sediment control blankets, silt fences, and sediment basins, help to trap and retain sediment on construction sites, preventing it from being washed away by rainfall or runoff. By keeping sediment in place, these products protect nearby water bodies from pollution and maintain the overall health of the ecosystem.

- Q: How do earthwork products contribute to erosion control on hillsides?

- Earthwork products, such as retaining walls, terraces, and erosion control blankets, play a crucial role in controlling erosion on hillsides. Retaining walls help to stabilize the soil and prevent it from washing away during heavy rainfall or runoff. Terraces create level areas on slopes, reducing the speed of water flow and allowing it to infiltrate into the soil, thus minimizing erosion. Erosion control blankets, made of biodegradable materials, provide a protective layer over the soil, preventing it from being displaced by wind or water. Overall, these earthwork products effectively contribute to erosion control on hillsides by stabilizing the soil, reducing water flow, and protecting it from external forces.

- Q: Are building materials the same as civil engineering materials?

- Civil engineering includes a wide range of materials, except for buildings, roads, bridges, tunnels and geotechnical materials that are related to civil engineering materials, but many of these materials are not used in industrial and civil construction.

- Q: A short duration of housing, and now have the same level of 42.5 for the silicate and slag cement selection. From the point of view of the completion of the construction period, what better cement should be used?

- Slag cement, early strength fast.

- Q: Are earthwork products resistant to impact and abrasion?

- Yes, earthwork products such as geomembranes and geotextiles are designed to be resistant to impact and abrasion. They are made from durable materials that can withstand physical stresses and provide long-lasting protection to the underlying soil or structures.

- Q: How do earthwork products enhance soil fertility?

- Earthwork products, such as compost and manure, enhance soil fertility by providing essential nutrients and organic matter to the soil. These products are rich in nitrogen, phosphorus, and potassium, which are vital for plant growth. When incorporated into the soil, earthwork products improve its structure, water holding capacity, and drainage, creating a more favorable environment for plant roots. Additionally, they promote the growth of beneficial microorganisms that break down organic matter, releasing nutrients for plants to absorb. Overall, earthwork products play a crucial role in replenishing and sustaining soil fertility, resulting in improved crop yields and healthier plants.

- Q: How do earthwork products affect the overall aesthetics of a project?

- Earthwork products can significantly impact the overall aesthetics of a project. The choice of materials, such as soil, rocks, and vegetation, can greatly influence the visual appeal of the landscape. Earthwork products, when thoughtfully selected and implemented, can enhance the natural beauty of the surroundings, create harmonious transitions between different elements, and contribute to the overall aesthetics of the project.

- Q: For the civil engineering students, material mechanics need to grasp to what extent? Focus on Pretty good reference book

- Material mechanics are as important as civil professionals as the Bible to Christians. The best degree to test more than 90 points. Almost every chapter is the focus, but the bending-related chapters are the most important.

- Q: What are the different load-bearing capacities of earthwork products?

- The load-bearing capacities of earthwork products can vary depending on the specific product and its intended use. Some common earthwork products, such as compacted fill materials, may have load-bearing capacities ranging from a few hundred pounds per square foot to several thousand pounds per square foot. However, it is important to consult engineering specifications and design guidelines to determine the exact load-bearing capacity required for a specific project.

Send your message to us

Geosynthetic Clay Liner(GCL) for Anti-seepage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords