Geocomposite Geosynthetic Clay Liner-GCL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

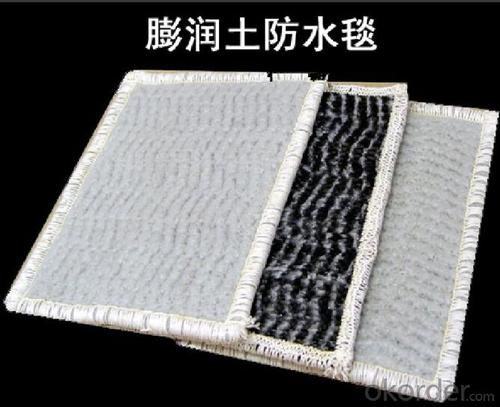

Geocomposite Geosynthetic Clay Liner

Introduction of GCL:

Geosynthetic Clay Liner is manufactured by three levels, including two levels of geotextile whose functions are protecting and strengthen to ensure shearing strength and tensile strength, inner content is Sodium bentonite clay. It is manufactured by nature layer silicate inorganic materials and has high expansibility and high water-absorbing capacity, when soak with low permeable capability, whose the main function is anti-seepage.

Features of GCL:

A:Form high density diaphragm under hydraulic pressure, the water permeable capability equals to 100 times density degree of 30cm clay when the thickness of GCL is 3mm. It has very good self water-retention property.

B:GCL is nature inorganic material, it won't aging or corrode even after long-time or surrounding changed, so it has permanent water proofing capability.

C:GCL is nature inorganic material, which is non-poisonous and harmless to human body, so it is environment protection material.

Application Filed of GCL:

Water storage, miniature reservoir, dam of reservoir, acequia,fish pond

Roof garden, basement etc.

Subway, railway, expressway, light industry, oil and metallurgy and other industry

Maintenance, repair and reinforcement of earth works

Environmental reform, garbage landfill, artificial lake or other landscape

Test Item | Test | Criteria |

Expansion coefficient | ASTM D 5890 | ≥24ml/2g |

Fluid loss | ASTM D 5891 | ≤18ml |

Bentonite clay weight of unit space | ASTM D 5993 | ≥4.8kg/sqm |

Tensile strength | ASTM D 4632 | ≥400N |

Peel strength | ASTM D 4632 | ≥65N |

Indicating flow | ASTM D 5887 | ≤1×10-8m3/sqm/sec |

Permeability | ASTM D 5887 | ≤5×10-275px/sec |

Tensile strength after soak | ASTM D 5321 | ≥24KPa typical |

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: What are the advantages of using gabion walls?

- There are several advantages of using gabion walls. Firstly, they provide excellent erosion control and soil stabilization, making them ideal for protecting slopes and riverbanks from erosion. Secondly, gabion walls are highly versatile and can be used in various applications such as retaining walls, noise barriers, and even artistic installations. Additionally, they are cost-effective compared to traditional construction methods, as they require minimal maintenance and are made from locally available materials. Moreover, gabion walls allow for natural drainage and prevent the accumulation of water, reducing the risk of flooding. Lastly, they are environmentally friendly, as they are made from wire mesh and natural stone, allowing for effective permeability and promoting biodiversity.

- Q: How can geocells be used in green roof systems?

- Geocells can be used in green roof systems by providing structural support and stabilization to the growing medium and vegetation. The cells can be filled with soil or other lightweight materials and arranged on the roof surface to create a network of compartments. This helps to distribute the weight evenly and prevent erosion or displacement of the growing medium. Additionally, geocells can aid in stormwater management by retaining water within the cells, promoting plant growth and reducing runoff. Overall, geocells enhance the durability, sustainability, and functionality of green roof systems.

- Q: What are the advantages of using geosynthetic materials in groundwater recharge projects?

- There are several advantages of using geosynthetic materials in groundwater recharge projects. Firstly, geosynthetic materials such as geotextiles or geogrids provide effective filtration, preventing the entry of sediment and contaminants into the groundwater during the recharge process. This helps in maintaining the quality of the recharged water. Secondly, geosynthetics help in controlling the flow of water, ensuring uniform distribution of water across the recharge area. This helps in maximizing the recharge efficiency and minimizing the loss of water due to uneven distribution. Additionally, geosynthetics offer high tensile strength and durability, allowing them to withstand the pressures and stresses associated with groundwater recharge projects. This ensures their long-term performance and reduces the need for frequent maintenance or replacement. Furthermore, geosynthetics are lightweight and easy to handle, making them cost-effective and convenient to install. They can be easily customized to suit the specific requirements of the recharge project, providing flexibility in design and implementation. Overall, the use of geosynthetic materials in groundwater recharge projects enhances the effectiveness, efficiency, and longevity of the recharge system, leading to sustainable water management and conservation.

- Q: How do geosynthetic erosion control products prevent soil loss?

- Geosynthetic erosion control products prevent soil loss by providing a physical barrier that stabilizes the soil and prevents it from being washed away by water or wind. They also help to promote vegetation growth, which further anchors the soil in place and enhances its resistance to erosion.

- Q: Are earthwork products suitable for water drainage systems?

- Yes, earthwork products can be suitable for water drainage systems. Earthwork products such as gravel, crushed stone, and geotextiles can be used effectively in water drainage systems to promote proper water flow, prevent erosion, and filter pollutants. These materials are commonly used in constructing French drains, retaining walls, and other drainage structures to manage and redirect excess water.

- Q: What are the benefits of using geosynthetic reinforcements in foundation applications?

- Geosynthetic reinforcements offer several benefits in foundation applications. Firstly, they enhance the stability and load-bearing capacity of the foundation, reducing settlement and preventing soil erosion. Secondly, they provide a cost-effective solution as they require less excavation and construction materials. Additionally, geosynthetic reinforcements are easy to install and maintain, saving time and labor. They also have high durability and resistance to environmental factors, ensuring long-term stability of the foundation. Overall, using geosynthetic reinforcements in foundation applications improves the performance, longevity, and cost-efficiency of the structure.

- Q: What are the different construction techniques using earthwork products?

- There are several different construction techniques that utilize earthwork products. Some of these techniques include cut and fill, embankment construction, earth dam construction, and trenching. Cut and fill involves excavating the earth from one area and using it to fill another area, creating level ground. Embankment construction involves building a raised soil structure, often used for roads or railways. Earth dam construction involves using compacted earth to create a barrier for water storage. Trenching involves digging narrow and deep excavations for various purposes such as utility installations or foundations. These techniques utilize earthwork products to shape and manipulate the land for construction purposes.

- Q: Can geosynthetics be used for reinforcement in road widening projects?

- Yes, geosynthetics can be used for reinforcement in road widening projects. Geosynthetics, such as geotextiles and geogrids, provide strength and stability to the road structure, reducing the need for additional materials and construction time. They improve the bearing capacity of the widened road and help control soil erosion, making them an effective solution for reinforcement in road widening projects.

- Q: How do geogrids aid in reinforcement of retaining walls in earthwork projects?

- Geogrids aid in the reinforcement of retaining walls in earthwork projects by providing additional tensile strength and stability to the structure. These grid-like materials are placed within the soil layers of the retaining wall, effectively distributing the forces exerted by the retained soil. This reinforcement helps prevent wall failure, improves overall stability, and extends the lifespan of the structure.

- Q: How do earthwork products contribute to landfill liner construction?

- Earthwork products, such as clay and geosynthetic clay liners (GCLs), play a crucial role in landfill liner construction. These materials are used to create an impermeable barrier that prevents contaminants from seeping into the surrounding soil and groundwater. Clay is often compacted to create a low-permeability layer, while GCLs consist of layers of geotextile and bentonite clay, offering enhanced hydraulic performance. By effectively containing waste within the landfill, earthwork products contribute to the overall integrity and environmental safety of landfill liner systems.

Send your message to us

Geocomposite Geosynthetic Clay Liner-GCL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords