Tri Dimensional Composite Drainage Geonet For Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 280000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

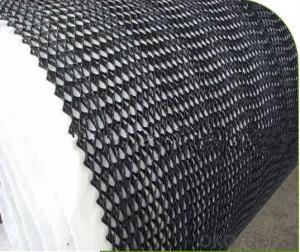

Introduction of Tri Dimensional Composite Drainage Geonet:

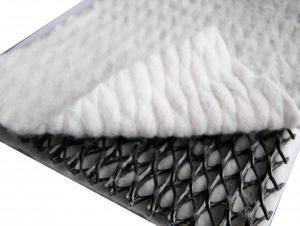

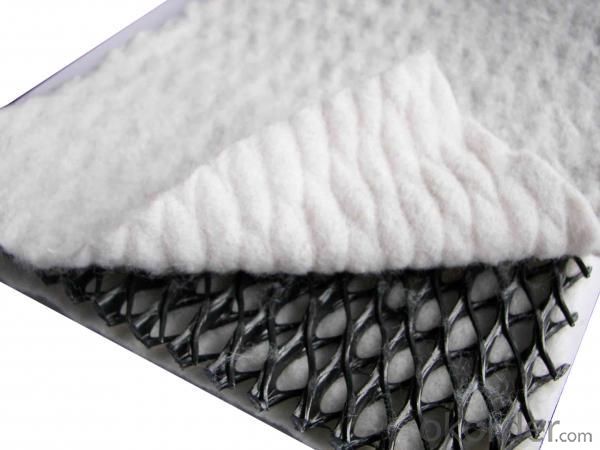

Tri-dimensional composite drainage geonet is made of a unique tri drimension geonet adhibit geotextile on both sides. It has the property of geotextile(filtration function) and geonet (drainage and protection) and provide a function system “filtration—drainage—protection”. The core of net with its unique tri-dimension structure can bear higher compressing load in construction and remain the certain thickness, provide good water conductivity.

Application of Tri Dimensional Composite Drainage Geonet:

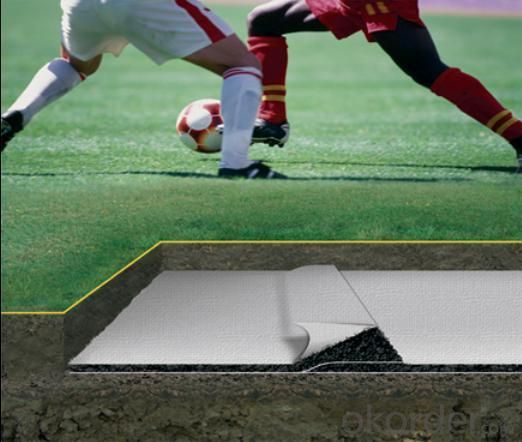

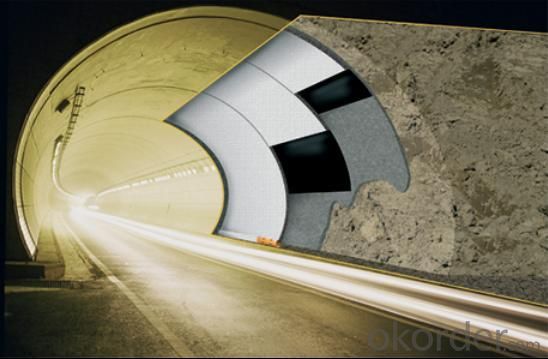

Landfill drainage; roadbed and road drainage; railway drainage ,tunnel drainage, underground structure drainage, the retaining back wall drainage, gardens and sports grounds drainage.

specifications and technical parameters of Tri dimensional composite drainage geonet:

Drainage network core | Units | Specifications | |||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 |

Thickness OV=20kpa | mm | 5.0 | 6.0 | 7.0 | 7.6 |

Hydraulic conductivity | m/s | K×10ˉ4 | K×10ˉ4 | K×10ˉ4 | K×10ˉ4 |

Elongation | % | <50 | <50 | <50 | <50 |

Tensile strength (core network) | KN/m | 8 | 10 | 12 | 14 |

Geotextiles | g/m2 | 200-200 | 200-200 | 200-200 | 200-200 |

The contrast of Tri dimensional composite drainage geonet and natural grit drainage layer

Application | Tri-dimension composite geonet for drainage | Natural Gravel |

Conducting and discharging Water and gas | Pass through strict quality control production line and have stable performance and good property of conducting water | The traditional gravel have complex composition and its drainage property change with its attribute. Its actual drainage property is much lower laboratory data for its contains of sand and dust. |

Load/Protection | Light, no more extral load on geomembrane and waste. Anti-pull, anti-compress, anti-impact and can prevent geomembrane from damage | Pressure on the waste, the keen stone can puncture and damage geomembrane. Often need other safeguard, such as thicker geotextile. |

Function | Four functions: drainage, separation, filtration and protection | Only drainage function, easy be blocked, and need accessorial filtration system. |

Construction and installation | Fast installation, easy for construction, without heavy machinery and professionals. Construction speed is 5-10 times of gravel. | Slow installation, bulky and heavy, need heavy machinery. High cost and have more difficulties with slope degree is more than 1V:4H. |

Environment | Raw material is polyethylene, nontoxic, no pollution, 100% recyclable products. | Relatively speaking, the gravel is scarce and precious resources. The ecological environment will be destroied when people mine gravel. |

Durability | Good anti-erosion, antioxidation, anti-atmospheric media and rain water. It have long-term and the best drainage property if used them along with the geotextile. | Be easily blocked, has poor durability. |

- Q: How are geotextile tubes used in sediment dewatering?

- Geotextile tubes are used in sediment dewatering by creating large containment structures that allow water to drain out while retaining the sediment. The tubes are usually filled with sediment slurry and then left to settle. As the water drains through the permeable geotextile fabric, the sediment particles are trapped inside, resulting in dewatered sediment that can be easily disposed of or repurposed.

- Q: What are the aesthetic options available for earthwork products?

- The aesthetic options available for earthwork products are diverse and can be tailored to individual preferences and project requirements. Some common options include different colors, textures, and finishes that can mimic natural materials like stone or wood. Additionally, various patterns, shapes, and sizes can be incorporated into earthwork products to create unique and visually appealing designs.

- Q: What are the key considerations when using geosynthetic reinforcements in bridge abutments?

- Some key considerations when using geosynthetic reinforcements in bridge abutments include the type and strength of the geosynthetic material, proper installation techniques, compatibility with surrounding soils, and design considerations such as load distribution and settlement control. Additionally, factors like durability, maintenance requirements, and cost-effectiveness should also be taken into account to ensure the long-term effectiveness and stability of the bridge abutments.

- Q: What are the long-term durability and lifespan of earthwork products?

- The long-term durability and lifespan of earthwork products can vary depending on various factors such as the quality of materials used, the construction techniques employed, and the level of maintenance provided. However, when properly designed, constructed, and maintained, earthwork products can have a substantial lifespan, often spanning several decades or even longer. Regular inspections, repairs, and necessary reinforcements can help ensure their durability and extend their lifespan.

- Q: What are the different sizes and dimensions available for earthwork products?

- The sizes and dimensions available for earthwork products vary depending on the specific product and its intended use. Common sizes for products such as gravel, sand, or soil can range from small bags or buckets to larger bulk quantities measured in cubic yards or tons. Other earthwork products like retaining walls, culverts, or erosion control materials come in various dimensions and shapes to suit specific construction or landscaping needs. It is best to consult with a supplier or manufacturer to determine the available sizes and dimensions for the specific earthwork product you are interested in.

- Q: Can earthwork products be used for constructing outdoor sculptures?

- Yes, earthwork products can be used for constructing outdoor sculptures. Earthwork products, such as soil, clay, sand, and rocks, provide a natural and versatile medium for sculpting outdoor artworks. These materials can be shaped, molded, and carved to create various forms and textures, allowing artists to express their creativity and bring unique sculptures to life in outdoor settings.

- Q: Can gabion walls be used for earthwork projects?

- Yes, gabion walls can be used for earthwork projects. Gabion walls are wire cages filled with stones, and they are commonly used in earthwork projects for erosion control, slope stabilization, and retaining walls. The flexibility and strength of gabion walls make them suitable for various earthwork applications.

- Q: Can earthwork products be used for constructing raised beds in gardens?

- Yes, earthwork products such as soil, compost, and mulch can be used for constructing raised beds in gardens. These materials can be used to create the foundation and fill for the raised beds, providing a fertile environment for plants to grow. Additionally, earthwork products can help improve drainage, retain moisture, and enhance the overall health and productivity of the garden beds.

- Q: What are the benefits of using geogrids in reinforced soil structures?

- Using geogrids in reinforced soil structures offers several benefits. Firstly, geogrids provide enhanced stability to the soil by distributing and transferring loads, reducing the risk of slope failure or settlement. They can also increase the bearing capacity of the soil, allowing for the construction of structures on weak or soft ground. Additionally, geogrids improve the overall performance of the reinforced soil structure by preventing soil erosion and retaining the structure's shape. They also minimize differential settlement, which helps in maintaining the integrity and longevity of the structure. Furthermore, geogrids are cost-effective compared to traditional construction methods as they require less excavation, backfill material, and labor. They are easy to install, lightweight, and can be customized to fit specific project requirements. Overall, the use of geogrids in reinforced soil structures provides increased stability, improved performance, cost savings, and a longer lifespan for the structure.

- Q: What is the purpose of using geotextile tubes in dredging projects?

- The purpose of using geotextile tubes in dredging projects is to provide efficient and effective dewatering and containment solutions. These large, fabric tubes are filled with sediment and water from the dredging process, allowing the water to drain out while retaining the solid material. This helps to separate and consolidate the dredged material, making it easier to dispose of or repurpose. By using geotextile tubes, dredging projects can minimize environmental impact and manage sediment in a controlled manner.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port,China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; Russian; Spanish |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Tri Dimensional Composite Drainage Geonet For Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 280000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches