Geosynthetic Clay Liner (GCL) /Lake Hydraulic Barriers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

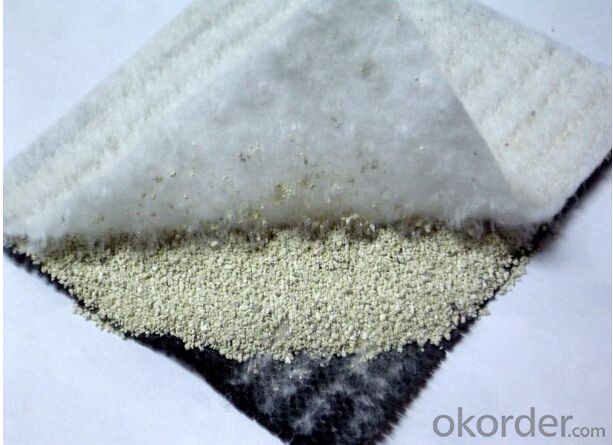

Geosynthetic Clay Liner (GCL) /Lake Hydraulic Barriers

Specification:

Mass per unit ≥ 4000g / m²

Width: 4-6 m

size: 5.8 x 30m , or customized

bentonite sandwiched between two layers of geotextile

Features:

1) compacted with clay liner, it has the advantages of

small size, light weight, good flexibility and compactibility

2) easy for construction and suitable for uneven settlement.

3) not affected by temperature

4) permanent waterproofness

5) eco-friendly

Applications:

Landfill sealing

Liquid containment

Secondary containment

Mining

GCL Technical Index

Item | Specification | ||||

GCL-NP | GCL-OF | GCL-AH | |||

Mass per unit g/m2 | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ||

GCL expansion index ml/2g | ≥24 | ≥24 | ≥24 | ||

Blue absorption power g/100g | ≥ 30 | ≥ 30 | ≥ 30 | ||

Tensile Strength N/ 100mm | ≥ 600 | ≥ 700 | ≥ 600 | ||

Elongation at maximum load % | ≥ 10 | ≥ 10 | ≥ 8 | ||

Peel strength N / 100mm | Nonwoven geotextile and woven geotextile | ≥ 40 | ≥ 40 | - | |

PE geommebrane and nonwoven geotextile | - | ≥ 30 | - | ||

Permeability coefficient m/s | ≤ 5.0x10-11 | ≤ 5.0x10-12 | ≤ 1.0x10-12 | ||

Hydrostatic pressure resistant | 0.4 Mpa , 1h, no leakage | 0.6 Mpa ,1h,no leakage | 0.6Mpa ,1h, no leakage | ||

Filter loss ml | ≤ 18 | ≤ 18 | ≤ 18 | ||

Durability of bentonite ml/ 2g | ≥ 20 | ≥ 20 | |||

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: What are the benefits of using geosynthetic clay liners in mining operations?

- Geosynthetic clay liners offer several benefits in mining operations. Firstly, they provide excellent containment of fluids, preventing the leakage of potentially harmful materials into the surrounding environment. Additionally, they have a high resistance to puncture and tear, ensuring the integrity of the liner even in challenging conditions. Geosynthetic clay liners also have a self-sealing ability, which helps to maintain their effectiveness over time. Moreover, their flexibility allows for easy installation, reducing both time and cost in mining operations. Overall, the use of geosynthetic clay liners promotes environmental protection, cost-efficiency, and operational safety in mining activities.

- Q: How are earthwork products manufactured?

- Earthwork products are typically manufactured through a two-step process. Firstly, the raw materials, such as soil, clay, or gravel, are excavated or sourced from quarries. These materials are then processed, often through crushing, screening, and mixing, to achieve the desired consistency and quality. Secondly, the processed materials are molded or shaped into specific forms, such as bricks, blocks, or panels, using various techniques like compression, extrusion, or vibration. These manufactured earthwork products are then cured or dried before being ready for use in construction projects.

- Q: Are earthwork products suitable for foundation reinforcement?

- Yes, earthwork products can be suitable for foundation reinforcement. Earthwork products such as geotextiles, geogrids, and geocells can provide effective reinforcement to stabilize soil, improve load-bearing capacity, and prevent soil erosion. These products are commonly used in various construction projects to enhance the strength and stability of foundations.

- Q: What are the different types of geotextile fabric properties?

- Some of the different types of geotextile fabric properties include filtration, separation, reinforcement, erosion control, and drainage.

- Q: Can earthwork products be used in sound barriers?

- Yes, earthwork products can be used in sound barriers. Earthwork products such as soil, rocks, and other materials can be used to construct sound barriers that effectively reduce noise pollution. These materials can be shaped and arranged to create a physical barrier that absorbs, reflects, and diffuses sound waves, thus providing a quieter environment.

- Q: Are earthwork products suitable for use in pipeline construction?

- Yes, earthwork products are suitable for use in pipeline construction. Earthwork products such as geotextiles, geogrids, and erosion control materials are commonly used in pipeline construction projects to provide soil stabilization, erosion control, and support. These products help to enhance the stability and longevity of the pipeline by preventing soil erosion, reinforcing weak soil, and improving drainage. Additionally, earthwork products also aid in the protection of the pipeline from external factors like harsh weather conditions and potential ground movements. Overall, earthwork products play a crucial role in ensuring the successful construction and maintenance of pipelines.

- Q: Are there any specific earthwork products available for mining reclamation?

- Yes, there are specific earthwork products available for mining reclamation. These products include materials such as topsoil, soil amendments, erosion control blankets, and geosynthetic liners. These products are designed to restore and stabilize the land after mining activities, promoting vegetation growth and preventing erosion.

- Q: Are there any earthwork products specifically designed for playground construction?

- Yes, there are earthwork products specifically designed for playground construction. Some common examples include rubber mulch, engineered wood fiber, and artificial turf. These materials are used to create a safe and cushioned surface for children to play on, reducing the risk of injuries. Additionally, there are various drainage systems and retaining wall solutions available that are specifically designed for playground construction to ensure proper water management and prevent erosion.

- Q: What are the civil engineering materials?

- Cement: general portland cement, ordinary portland cement, a large number of mixed materials, Portland cement

- Q: How do geosynthetic liners contribute to groundwater recharge in water storage facilities?

- Geosynthetic liners help to prevent water from leaking out of water storage facilities, ensuring that more water is retained. This retained water can then slowly seep into the ground, replenishing groundwater sources and contributing to groundwater recharge.

Send your message to us

Geosynthetic Clay Liner (GCL) /Lake Hydraulic Barriers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords