Composite Soil Drainage Network for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite Soil Drainage Network for Architectural Engineering

Description Of Composite Soil Drainage Network for Architectural Engineering

Composite material is a general term for the synthetic materials used in civil engineering. As a kind of civil engineering materials, it is to synthetic polymers, such as plastics, chemical fiber, synthetic rubber as raw material, made of various types of products, placed inside the soil, surface, or various kinds of soil play to strengthen or to protect the soil. The application of the technology of soil engineering synthetic materials will be divided into the type of the material of the soil, the soil, the soil, the special material and the composite. The special materials for the special materials include the soil engineering film bag, the soil engineering net, the geotechnical mesh pad, the soil working chamber, the soil texture, the bentonite mat, the polystyrene foamed plastics (EPS), etc.. The composite material is made from the above mentioned materials, such as composite coating, composite material, composite material, composite waterproof and drainage (drainage), etc..

Main Features of Composite Soil Drainage Network for Architectural Engineering

The advantages of the composite is that the weight is light, and the overall continuity is good (can be made into a large area of the whole), construction is convenient, high tensile strength, corrosion resistance and resistance to microorganisms. The disadvantage is that, without special treatment, anti ultraviolet ability, such as exposure to ultraviolet radiation, is easy to aging, but if not directly exposed, the anti aging and durability performance is still high.

Applications of Composite Soil Drainage Network for Architectural Engineering

1, for the stability of highway, railway roadbed.

2, used to bear the weight of the embankment and shallow water treatment.

3, used to prevent the landslide and the load of the gravity of the hybrid retaining wall.

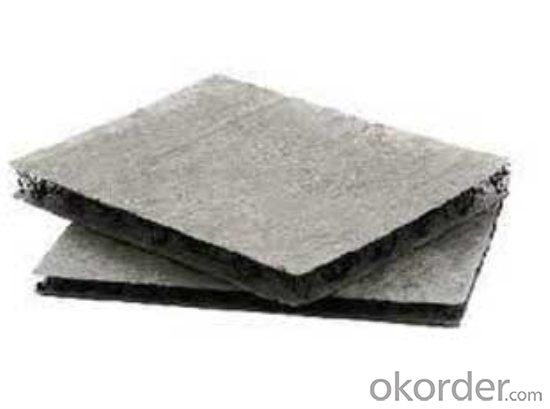

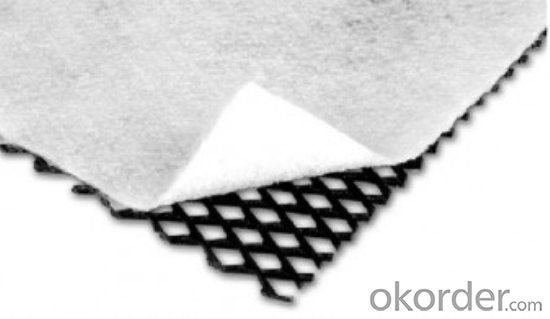

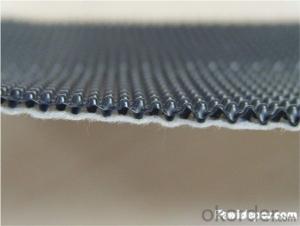

IMages of Composite Soil Drainage Network for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: How do erosion control blankets help in slope re-vegetation in earthwork projects?

- Erosion control blankets help in slope re-vegetation in earthwork projects by providing a protective layer over the soil. These blankets are typically made of biodegradable materials, such as straw or coconut fibers, and are placed on the slope to prevent erosion caused by wind, rain, and water flow. They help retain moisture, prevent soil from being washed away, and promote the growth of vegetation by creating an ideal environment for seed germination. Additionally, erosion control blankets also offer protection against weed growth and regulate soil temperature, ultimately aiding in the successful establishment of vegetation on slopes.

- Q: How are geosynthetic clay liners used in landfill lining?

- Geosynthetic clay liners are used in landfill lining to create a barrier that prevents the leakage of harmful substances into the surrounding environment. They consist of a layer of bentonite clay sandwiched between geotextile fabrics. The clay liner swells upon contact with water, forming a dense impermeable barrier that prevents the migration of contaminants from the landfill. Additionally, the geotextile fabrics provide reinforcement and stability to the liner system. This combination of materials effectively controls the flow of liquids and gases within the landfill, reducing the risk of pollution and protecting the surrounding ecosystems and water sources.

- Q: What are the requirements for civil engineering materials?

- I think it's a requirement. The The Product to be qualified

- Q: How do geosynthetic meshes help in soil stabilization for embankments?

- Geosynthetic meshes help in soil stabilization for embankments by providing reinforcement and confinement to the soil, improving its strength and stability. These meshes act as a barrier against soil erosion, preventing the loss of soil particles and maintaining the embankment's integrity. The meshes also distribute the applied loads more evenly across the embankment, reducing stress concentrations and the potential for slope failure. Additionally, geosynthetic meshes allow for efficient drainage of excess water, preventing saturation and maintaining the embankment's stability in wet conditions.

- Q: Can earthwork products be used in slope stabilization projects?

- Yes, earthwork products can be used in slope stabilization projects.

- Q: Are earthwork products suitable for underground stormwater storage?

- Yes, earthwork products such as geosynthetic materials, geotextiles, and geogrids are commonly used for underground stormwater storage systems. These products provide effective soil stabilization and reinforcement, preventing erosion and maintaining the integrity of the storage structure. Additionally, they enhance the permeability of the surrounding soil, allowing water to infiltrate and be stored underground, thereby reducing the risk of flooding.

- Q: Can earthwork products be used for creating outdoor seating in parks?

- Yes, earthwork products such as soil, gravel, or rocks can be utilized for creating outdoor seating in parks. These materials can be shaped and arranged to build benches, seating walls, or terraces, providing functional and natural seating options for park visitors.

- Q: What are the advantages of using geotextile mats in erosion control blankets?

- Geotextile mats offer several advantages in erosion control blankets. Firstly, they provide excellent stability and reinforcement to the soil, preventing erosion and soil movement. Secondly, they allow water to pass through while retaining soil particles, facilitating proper drainage and preventing waterlogging. Additionally, geotextile mats enhance vegetation growth by retaining moisture and providing a conducive environment for plant roots to establish. Lastly, these mats are durable, cost-effective, and easy to install, making them a practical choice for erosion control projects.

- Q: Can earthwork products be used in underground storage tank construction?

- Yes, earthwork products can be used in underground storage tank construction. These products, such as compacted soil or clay, can be used to create a stable and secure foundation for the tank. Additionally, they can be used to backfill around the tank to provide support and prevent any movement or collapse.

- Q: What are the benefits of using geocells for load support in railways?

- The benefits of using geocells for load support in railways are improved track stability, enhanced load distribution, reduced settlement, increased bearing capacity, and extended service life of the tracks. Geocells provide a sustainable and cost-effective solution that helps prevent track deformations, soil erosion, and track failures, resulting in safer and more efficient railway operations.

Send your message to us

Composite Soil Drainage Network for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords