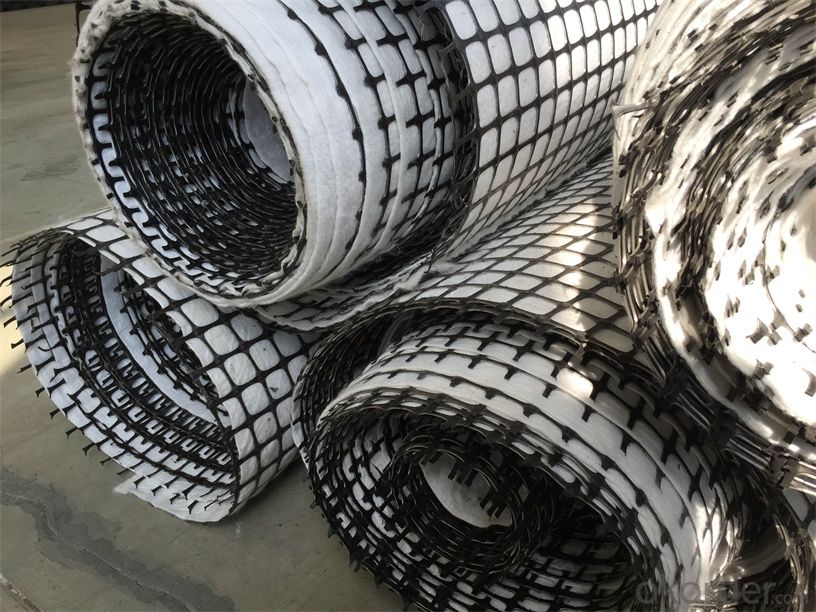

Tri-dimension Composite Geonet for Drainage with Width of 5m

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

It is a new type drainage material, made of geonet and non woven geotextile, a unique tridimension geonet adhibited geotextile on both sides. It has the property of geotextile and geonet.

Product Application

Landfill drainage, roadbed and road drainage, railway drainage, tunnel drainage, underground structure drainage, the retaining back wall drainage, gardens and sports grounds drainage.

Product Specifications:

Geonet thickness: 5m-8m.

Width: 2m-4m.

Weight of non woven geotextile: 200g/m2.

Length: according to clients' request

Packaging Details:pp woven bags or at your request

Delivery Detail:15 days

Product Property:

It has the property of geotextile and geonet and provide a function system filtration-drainage-protection.

The core of net with its unique tri-dimension structure can bear higher compression load in construction and remain the cerain thickness, provide good water conductivity.

FAQ:

Q: What kind of payments could you support?

A: T/T, L/C, Cash are accepted.

Q: Can we visited your factory?

Y: Yes, warmly welcome to visit our factory.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How are earthwork products used in construction?

- Earthwork products are commonly used in construction for various purposes. They are primarily used for grading and leveling the construction site, creating a stable foundation for buildings and structures. These products, such as soil, sand, gravel, and rocks, can also be used for backfilling, filling trenches, and compacting surfaces to ensure proper drainage and stability. Additionally, earthwork products are utilized in the construction of roads, embankments, dams, and other infrastructure projects to provide structural support and prevent erosion.

- Q: Can geomembranes be used for secondary containment?

- Yes, geomembranes can be used for secondary containment. They are impermeable barriers that can effectively contain and prevent the escape of liquids or hazardous materials. Geomembranes are commonly used in various industries, such as oil and gas, chemical, and waste management, to provide an additional layer of protection against potential leaks or spills.

- Q: How do earthwork products differ from regular construction materials?

- Earthwork products are specifically designed and used for the construction and manipulation of the earth's surface, such as soil, rocks, and other natural materials. They differ from regular construction materials in that they are primarily used for excavation, grading, and filling purposes, rather than for the structural components of a building or infrastructure. Earthwork products are typically used to shape the topography of a site, create foundations, embankments, or trenches, and ensure proper drainage and stability, while regular construction materials, such as concrete, steel, or wood, are used for building the actual structures and providing strength and support.

- Q: Can earthwork products be used in flood control systems?

- Yes, earthwork products can be used in flood control systems. Earthworks involve the manipulation of soil and other materials to create structures like berms, levees, and floodplains, which are essential components of flood control systems. These structures help to redirect, contain, or absorb excess water during periods of heavy rainfall or flooding, thereby reducing the risk of damage to surrounding areas.

- Q: Can earthwork products be used for creating outdoor shower areas?

- Yes, earthwork products can be used for creating outdoor shower areas. These products, such as natural stones, pebbles, and gravel, can be used to create a beautiful and functional shower area in an outdoor setting. They can be used for constructing the shower floor, walls, and even as a decorative element in the overall design. Additionally, earthwork products are durable and can withstand outdoor conditions, making them suitable for creating outdoor shower areas.

- Q: For the civil engineering students, material mechanics need to grasp to what extent? Focus on Pretty good reference book

- Are you civil Material mechanics is the branch of the three major mechanics, of course, important, the design of the basis of the need to clearly grasp the material mechanics, such as the size of the beam design and check these in the engineering practice are directly used, many famous university entrance examination course is material Force rather than knot force can see its importance

- Q: Can earthwork products be used for seawall construction?

- Yes, earthwork products can be used for seawall construction. These products, such as geotextiles, geogrids, and geocells, are often employed in seawall construction projects to provide erosion control, stability, and reinforcement to the structure.

- Q: What are the different load-bearing capacities of earthwork products?

- The load-bearing capacities of earthwork products vary depending on factors such as the type of material used, the compaction level, and the intended application. Some common load-bearing capacities for earthwork products include lightweight fill materials capable of supporting light loads, such as grass and topsoil, which may have a load-bearing capacity ranging from 50-75 pounds per square foot. On the other hand, compacted gravel or crushed stone can have load-bearing capacities ranging from 100-200 pounds per square foot, making them suitable for heavier loads. Additionally, engineered materials like geogrids or geotextiles can significantly enhance load-bearing capacities by providing reinforcement and stabilization, allowing for even greater weight distribution. Ultimately, it is essential to consider the specific requirements of a project and consult with professionals to determine the most suitable load-bearing capacity for earthwork products.

- Q: What are the advantages of using geosynthetic materials in road pavement rehabilitation?

- There are several advantages of using geosynthetic materials in road pavement rehabilitation. Firstly, geosynthetics can enhance the structural integrity of the pavement by providing additional strength and stability. They can act as reinforcement layers, improving the load-bearing capacity of the road and reducing the risk of pavement failure. Secondly, geosynthetics can help in minimizing cracking and rutting in the pavement. They have excellent tensile strength, which allows them to distribute stresses and strains caused by traffic loading, preventing the formation of cracks and ruts. This leads to a longer lifespan for the road and reduces the need for frequent repairs. Another advantage is that geosynthetics can improve drainage within the pavement system. They can act as a drainage layer, facilitating the flow of water away from the road surface. This helps in preventing water accumulation, which can cause damage to the pavement structure over time. Furthermore, geosynthetics provide a cost-effective solution for road pavement rehabilitation. They are lightweight and easy to install, resulting in reduced construction time and labor costs. Additionally, their durability and longevity contribute to long-term savings as they decrease the need for frequent maintenance and repairs. Overall, the use of geosynthetic materials in road pavement rehabilitation offers numerous advantages, including increased strength, reduced cracking and rutting, improved drainage, and cost-effectiveness.

- Q: What are the benefits of using geocells for load support in railways?

- The benefits of using geocells for load support in railways are improved track stability, enhanced load distribution, reduced settlement, increased bearing capacity, and extended service life of the tracks. Geocells provide a sustainable and cost-effective solution that helps prevent track deformations, soil erosion, and track failures, resulting in safer and more efficient railway operations.

Send your message to us

Tri-dimension Composite Geonet for Drainage with Width of 5m

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords