CE Certified Vegetated Polyester Geogrids Hot

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

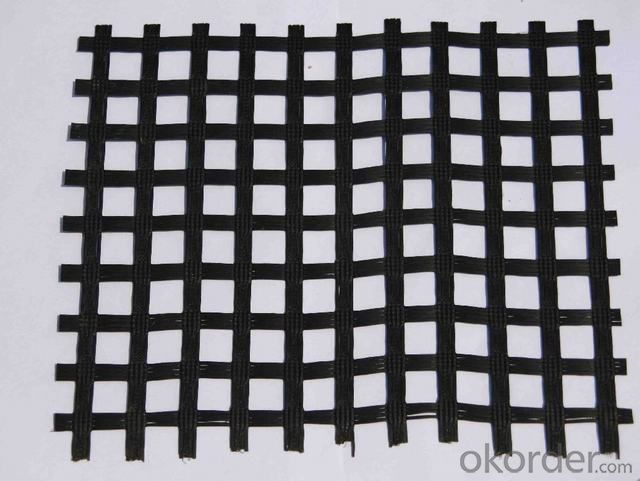

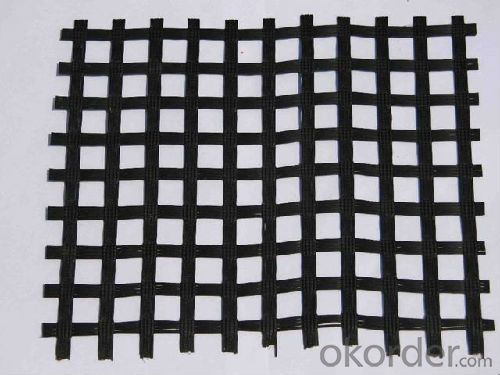

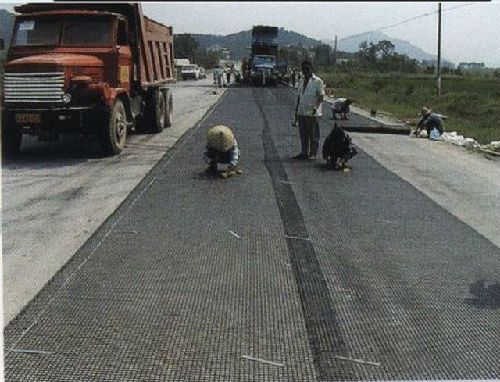

Biaxial geogrids are used in base reinforcement applications such as roads and parking lots. Biaxial geogrids provide good tensile strength in both principle directions. Biaxial geogrids primary functions: reinforcement. Secondary functions: none. Lianyi has many different styles of biaxial geogrids available

Tensile | Warp | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 | ≥150 |

Strength | ||||||||

(KN) | Weft | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 | ≥150 |

Elogation | Fiberglass | <4 % | 4 % | 4 % | 4 % | 4 % | 4 % | 4 % |

Polyester | <13% | 13% | 13% | 13% | 13% | 13% | 13% | |

Mesh size(mm) | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | |

25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | ||

42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | ||

50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | ||

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

(Fiberglass) | ||||||||

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature | Fiberglass | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resistant (°C) | Polyester | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resin | Fiberglass | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 |

Content (%) | polyester | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% |

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement and increased tensile strength to the soil. These grid-like structures are placed within the levee's soil layers, creating a stable and cohesive system. The geogrids distribute the applied loads more evenly and prevent soil erosion, enhancing the overall stability and strength of the levee structure.

- Q: What are the factors that affect the performance of geogrids under cyclic loading?

- Some factors that can affect the performance of geogrids under cyclic loading include the type and quality of the geogrid material, the installation method, the magnitude and frequency of the cyclic loading, the soil conditions, and the presence of any additional reinforcement or confinement.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in clayey soils?

- Geogrids improve the performance of mechanically stabilized slopes in clayey soils by providing reinforcement and enhancing the overall stability of the slope. The geogrids act as a tension element, distributing the tensile forces and reducing the potential for slope failure. They increase the shear strength of the soil, preventing excessive movement and reducing the risk of slope deformation. Additionally, geogrids help to control the lateral spreading of the soil by confining it within the reinforced zone, thereby improving the overall performance and longevity of the slope in clayey soils.

- Q: Are geogrids suitable for use in soil reinforcement for pipeline crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline crossings. Geogrids are commonly used in such applications due to their ability to effectively distribute loads, improve soil stability, and prevent soil erosion. They provide a cost-effective solution for enhancing the strength and durability of the soil, ensuring the safe and reliable installation of pipelines.

- Q: What are the factors that affect the quality of glass fiber reinforced plastic grid

- The first is glass fiber. Glass steel fiber can improve the tensile strength and the elastic modulus of FRP pultruded grating plate, but also can reduce shrinkage, improve the heat deformation temperature and low temperature impact strength, therefore is glass steel grille pultrusion cover the main load-bearing part.

- Q: Can geogrids be used in shoreline protection against wave action?

- Yes, geogrids can be used in shoreline protection against wave action. Geogrids are commonly used to stabilize soil and prevent erosion. When installed along the shoreline, geogrids can help absorb the energy of the waves, reduce erosion, and provide protection to the shoreline. They are often combined with other materials, such as rocks or vegetation, to create an effective barrier against wave action.

- Q: What are the differences between geogrids and geocells?

- Geogrids and geocells are both geosynthetic materials used in civil engineering applications, but they have some key differences. Geogrids are typically flat, grid-like structures made of polymer materials such as polyester, polypropylene, or fiberglass. They are used to provide tensile strength and stability to soil and aggregate materials. Geogrids are commonly used for soil reinforcement, slope stabilization, and retaining wall construction. They are installed by laying them on the surface or embedding them within the soil. On the other hand, geocells are three-dimensional honeycomb-like structures made of high-density polyethylene (HDPE) or polypropylene (PP). Geocells are used for soil confinement and erosion control. They are primarily used to create stable and load-bearing structures on weak or unstable soils. Geocells are installed by expanding and interconnecting them to form a cellular network, which is then filled with soil, aggregate, or other materials. In summary, the main difference between geogrids and geocells lies in their structure and application. Geogrids provide tensile strength and stability to soil, while geocells offer soil confinement and erosion control capabilities.

- Q: Want to know what is the advantage of unidirectional polyester geogrid and two-way existence? What are the differences between the two?For example, function, cost, construction

- First talk to the function of it, compared with the similar functions, There are both advantages and disadvantages., but the cost of bidirectional geogrid is more expensive! Construction is the same! The difference lies in the cost! Thank you

- Q: How do geogrids improve the stability of shorelines?

- Geogrids improve the stability of shorelines by providing reinforcement and preventing soil erosion. They are typically installed beneath the surface of the shoreline, creating a strong and stable foundation. Geogrids help distribute the load of the soil and wave forces, reducing the risk of slope failure or collapse. Additionally, they enhance the soil's resistance to erosion caused by waves, currents, or wind, ultimately preserving the shoreline's integrity and preventing further degradation.

- Q: Can geogrids be used in ground reinforcement for sports fields?

- Yes, geogrids can be used in ground reinforcement for sports fields. Geogrids provide stability to the soil, prevent soil erosion, and distribute the load evenly, making them an effective solution for reinforcing the ground in sports fields.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

CE Certified Vegetated Polyester Geogrids Hot

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords