Geogrids Manufacturer High Tensile Strength Polyester Geogrid with CE Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 19999999 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

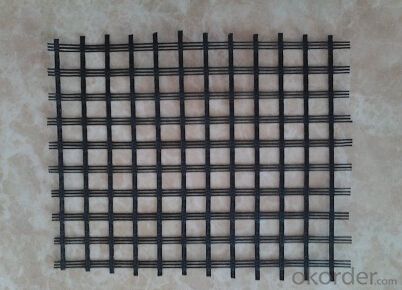

Description of High Tensile Strength Polyester Geogrid

we have CE , ISO9001 certificate..Polyester Geogrid for Road Railway Highway Tunnel is Made from PET fiber by weaving technology after gummed processing

Specification of High Tensile Strenth Polyester Geogrid with CE Certifcate:

1.Strength: 20x20kn/m--600x600kn/m, such as :60/30, 60/60, 80/30, 120/30, 150/30, 200/30 etc.

2.Polyester Geogrid coated with PVC, Bitumen, SBR

3.Elongation:10% and 13%

4.Width: 1--6m

5.Packing:50m or100m/roll,

PE film outside, plstic tube inside.also can be made according clinet's need.

Application of High Tensile Strenth Polyester Geogrid with CE Certifcate:

(1)Roadbed reinforcement of road and railway, crack prevention, increase of roadbed strength;

(2)Reinforcement and stabilization of riverside, embankment and side slope;

(3)Dyke reinforcement on soft ground for stress evenness, sedimentation adjustment, increase of stability and loading capacity of fundus;

(4)Reinforcement of the surface of road and bridge

Property of Polyester Geogrid for Road Railway Highway Tunnel

I. High tensile strength

2. Low elongation

3. Anti-erosion, anti-aging

4. Good affinity with base material

5. Lig ht weig ht, water d rainage

FAQ

What is your advantages ?

I. Not easy to produce static after friction. In the coal mine, surface static resistance average is

Below lx109Q

2. Good flame retardant performance

3. Strong anti-corrosion and rust resistance

4. High bearing capacity, low elongation

- Q: Can geogrids be used in ground improvement projects?

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly used to reinforce and stabilize soil, improving its bearing capacity and preventing soil erosion. They are effective in a variety of ground improvement applications such as road construction, retaining walls, and slope stabilization.

- Q: How do geogrids help in load distribution?

- Geogrids help in load distribution by providing reinforcement and stabilization to the soil. They distribute the applied load across a wider area, reducing stress concentration on the soil. This prevents excessive settlement and deformation of the ground, improving the overall stability and load-bearing capacity of the structure.

- Q: How do geogrids improve the performance of bridge abutments?

- Geogrids improve the performance of bridge abutments by providing reinforcement and stability to the soil surrounding the abutments. They distribute the loads more evenly, preventing soil erosion and reducing settlement. Additionally, geogrids enhance the overall strength and durability of the abutment, allowing it to withstand heavy traffic loads and natural forces such as earthquakes.

- Q: Can geogrids be used in slope protection systems?

- Yes, geogrids can be used in slope protection systems. Geogrids are commonly used to reinforce slopes by providing stability and preventing soil erosion. They can be installed horizontally or vertically to improve the strength of the soil and enhance the overall performance of slope protection systems.

- Q: What is the recommended geogrid aperture size?

- The recommended geogrid aperture size depends on various factors such as the specific application, soil conditions, and engineering requirements. It is best to consult with a geotechnical engineer or a specialist in geogrid design to determine the appropriate aperture size for a particular project.

- Q: What is the market price of the geotechnical grid in 2017

- (2) 0.3m thick medium (coarse) sand, artificial with mechanical leveling, 25T vibratory roller static pressure two times.

- Q: Can geogrids be used in reinforcement of bridge abutments and wing walls?

- Yes, geogrids can be used in the reinforcement of bridge abutments and wing walls. Geogrids are a type of geosynthetic material that offer high tensile strength and can provide stability and reinforcement to soil structures. They are commonly used to enhance the performance and durability of retaining walls, slopes, and embankments. In the case of bridge abutments and wing walls, geogrids can help distribute the loads, improve soil stability, and prevent soil erosion, ultimately increasing the overall strength and longevity of the structure.

- Q: What are the technical parameters and testing standards of the tensile creep testing machine

- 900mm; 5 effective width: 350mm; 6: 0.03mm; precision measurement of displacement measurement error: 7 time less than 1%; 8 may refer to

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners in landfill covers?

- Yes, geogrids provide reinforcement to geosynthetic asphalt liners in landfill covers.

- Q: Can geogrids be used for reinforcement in asphalt overlays?

- Yes, geogrids can be used for reinforcement in asphalt overlays. They are commonly used to improve the structural integrity and durability of asphalt overlays by providing additional support and reducing the potential for cracking and rutting. Geogrids can help distribute the load more evenly, increase the tensile strength of the pavement, and enhance long-term performance.

Send your message to us

Geogrids Manufacturer High Tensile Strength Polyester Geogrid with CE Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 19999999 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords