Plastic Geogrids PP/PE/PET Manufacturer High Tensile Strength Triaxial Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

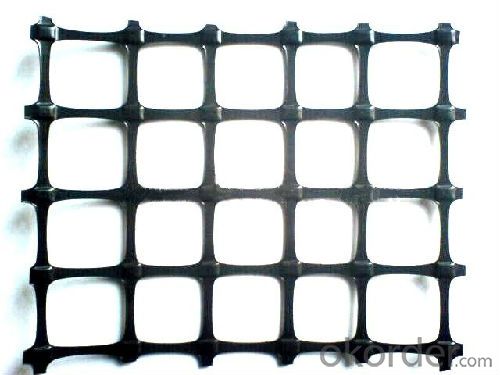

Plastic Geogrids PP/PE/PET Manufacturer High Tensile Strength Triaxial Geogrid

Quick Details

Type: Geocells

Place of Origin: Shandong, China (Mainland)

Material: HDPE, PPModel Number: TGDG

Material: <SPAN style="BORDER-BOTTOM: 0px; BORDER-LEFT: 0px; PADDING-BOTTOM: 0px; MARGIN: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 0px; FONT-FAMILY: inherit; WORD-WRAP: break-word; FONT-SIZE: 16px; VERTICAL-ALIGN: baseline; BORDER-TOP: 0px; BORDER-RIGHT: 0px; PADDING-TOP: 0px" class=attr-value title=Plastic-Steel,HDPE/PP>Plastic-Steel,HDPE/PP

color: black etc.

length: 50-100m(or at request)

sample: available

Packaging & Delivery

Standard exporting package , or as request |

within 10 days after the advanced payment |

Specifications

Geogrid

1.Tensile strength: 15~100KN/M

2.Color:black and etc.

3.Material:PP/PET

4.Certification:CE/ISO9001

Geogrid :

Picture

- Q: Geogrid construction must be folded back 2m wrapped in compacted packing on it?

- Edit this section of geogrid construction notesPaved geogrid should be smooth, paving layer after acceptance, to prevent longitudinal askew phenomenon, according to the width of paving layer or draw white thread, you can start paving, and then use the end of the nail fixed grid (nail 8, per meter wide uniform fixed distance) well, after the end of the fixed grid, with the paving machine will grill slowly pulled forward each shop, shop 10 meters long artificial tightening and straightening once, until a volume grating puwan, put the next volume, operation with a roll of puwan with roller 6T-10T from the starting point to begin the direction of rolling over, (steel rolling as road paving in the surface layer and the leveling layer, the machine is appropriate; such as grid laid directly on the concrete pavement, with the roller roller is appropriate) ground shop: Volume long unit as the laying of the long, the grid should be covered the long shop Full, then the overall check a paving quality, and then paving the next section, the next section of paving, grille and grille can be used lap length 10-15CM, and fixed with nails or wedge to shop in second, to the direction followed by analogy with operating requirements.

- Q: Can geogrids be used in mining operations?

- Yes, geogrids can be used in mining operations. Geogrids are commonly used in mining for various purposes such as soil stabilization, reinforcement of embankments, and slope stabilization. They provide strength and stability to the mining site, preventing soil erosion and enhancing safety during mining operations.

- Q: How do geogrids improve the performance of retaining walls?

- Geogrids improve the performance of retaining walls by providing tensile strength and reinforcement to the soil, thereby increasing the stability and load-bearing capacity of the wall. They prevent soil erosion and lateral movement, reducing the risk of wall failure. Additionally, geogrids distribute the applied loads more uniformly, minimizing differential settlement and reducing the overall stress on the retaining wall structure.

- Q: How many square meters of geogrid?

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Are geogrids resistant to biological degradation?

- Yes, geogrids are generally resistant to biological degradation.

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can affect the installation and survivability of geogrids in harsh environments. Firstly, the type and quality of the geogrid material plays a crucial role. Geogrids made from high-strength polymers or synthetic fibers are more likely to withstand extreme conditions. Secondly, the design and installation techniques used are important factors. Proper anchoring, tensioning, and overlap of geogrids can enhance their durability in harsh environments. Additionally, the soil type and its characteristics, such as cohesion and friction angle, can impact the performance of geogrids. The presence of aggressive chemicals, temperature fluctuations, and exposure to UV radiation are other factors that can affect their survivability. Overall, a thorough understanding of these factors and adherence to best practices during installation are essential for ensuring the successful functioning of geogrids in harsh environments.

- Q: Are geogrids resistant to high temperatures?

- Yes, geogrids are generally resistant to high temperatures. They are designed to withstand extreme temperature variations without losing their structural integrity or performance.

- Q: Can geogrids be used in erosion control on slopes and hillsides?

- Yes, geogrids can be used in erosion control on slopes and hillsides. Geogrids are widely used for reinforcement and stabilization purposes in such areas to prevent soil erosion and retain the stability of the slope or hillside. They provide additional support to the soil, reducing the risk of landslides and erosion by improving the structural integrity of the slope.

- Q: Glass fiber grating with large pulling force for Expressway

- Fiberglass geogrid is mainly used for old road reconstruction, the main purpose is to reduce reflection cracks.

- Q: How do geogrids help in reducing the need for excavation and replacement of poor soils?

- Geogrids help in reducing the need for excavation and replacement of poor soils by providing reinforcement to the soil, increasing its load-bearing capacity. This reinforcement allows for the construction of structures on weak or unstable soil without the need for extensive excavation and replacement. Geogrids distribute the load more evenly, reducing soil movement and potential settlement, thus eliminating the need for costly and time-consuming excavation and replacement processes.

Send your message to us

Plastic Geogrids PP/PE/PET Manufacturer High Tensile Strength Triaxial Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords