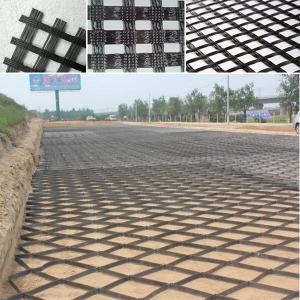

High Strength PP Biaxial Geogrid for Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

CMAX Biaxial geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching,

heating, longitudinal stretching and transverse stretching.

Performance:

Homogeneous structure, low creep, anti-aging and resisting acid and alkaline.

Applications:

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and

roadway in the coal mine.

Packing

FAQ

●How long have you been in international trade and geosynthetics industry?

10-year experience in international trade.

20-year experience in geosynthetics field.

●Which payment do you accept?

For you convinience,our payment can be L/C,TT,Westunion,paypal

●Can I know the width you can produce?

Of course we can,our width can be 1 to 6m

●How will you pack the products?

Usually we pack our products by woven bags,also we can do as your requirements

●We want to make sure quality,is free sample available?

We can supply free samples if you need.

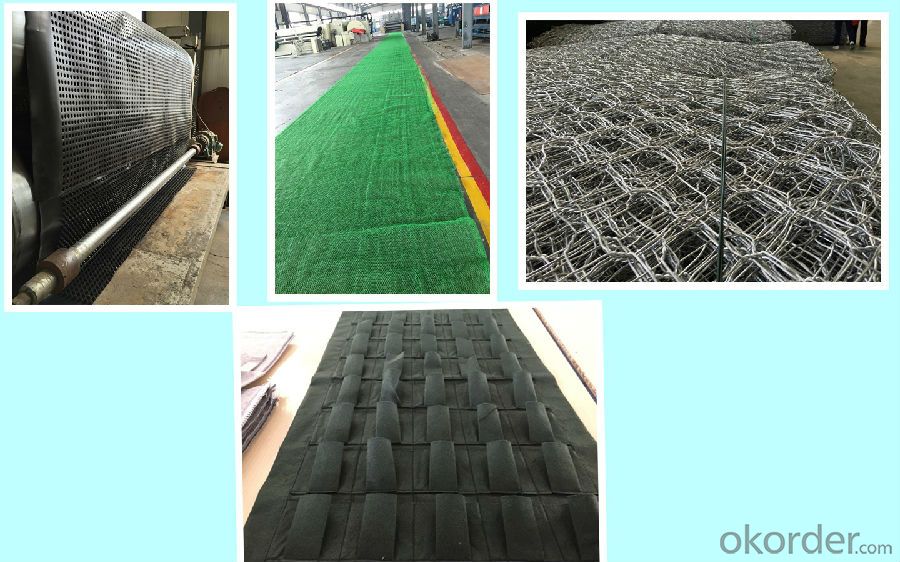

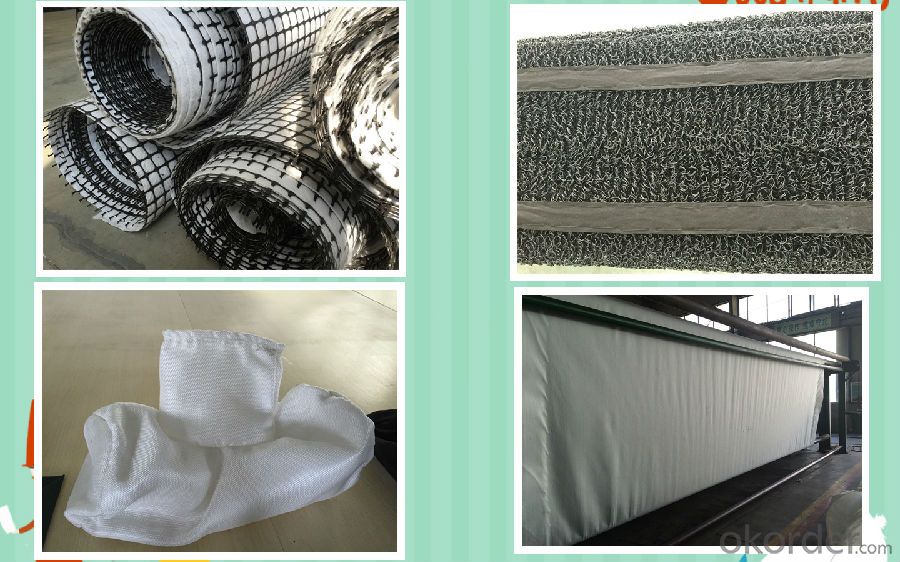

●Do you have other products?

Yes, we have, please check the pictures:

- Q: Especially in the curtain wall project

- There are plastic grille and glass fiber grille (fiberglass), as well as Geotextile

- Q: Can geogrids be used in reinforcement of dams and levees?

- Yes, geogrids can be used in the reinforcement of dams and levees. Geogrids are highly durable and can provide tensile strength to the soil, enhancing its stability and preventing erosion. By incorporating geogrids into the construction of dams and levees, the structures can better withstand the forces exerted by water pressure and natural disasters.

- Q: How do geogrids improve the performance of geocomposite drains?

- Geogrids improve the performance of geocomposite drains by providing reinforcement and stability to the drain system. They enhance the load-bearing capacity of the drain, prevent soil movement, and distribute the load more evenly. This helps in increasing the overall strength and longevity of the drain, improving its performance and effectiveness in draining water.

- Q: Who has the "highway geosynthetics geogrid" specification

- There is no integral download online, you need help please leave the mailbox number.

- Q: Can geogrids be used in agricultural applications?

- Yes, geogrids can be used in agricultural applications. They are commonly used as soil stabilization materials to reinforce and support the soil in areas such as farm roads, embankments, and retaining walls. Geogrids help improve load-bearing capacity, prevent soil erosion, and promote efficient water drainage, making them suitable for various agricultural needs.

- Q: How are geogrids installed in the field?

- Geogrids are typically installed in the field by first preparing the subgrade by removing any vegetation or loose soil. The geogrid is then rolled out and placed on top of the subgrade, ensuring it is properly aligned and covers the desired area. It is then secured in place using stakes, pins, or other anchoring methods. Finally, the geogrid is covered with a layer of fill material, such as soil or gravel, which is compacted to provide additional stability and load-bearing capacity.

- Q: Can geogrids be used in reinforcement of rail embankments and cuttings?

- Yes, geogrids can be used in the reinforcement of rail embankments and cuttings. Geogrids are commonly utilized in civil engineering projects to improve the stability and strength of soil structures. By incorporating geogrids into rail embankments and cuttings, the soil is effectively reinforced, preventing erosion, reducing settlement, and enhancing overall stability. This reinforcement technique helps to ensure the longevity and safety of rail infrastructure.

- Q: How to fill in the geogrid evaluation form

- What kind of geosynthetics are you looking at?

- Q: Geogrid prices and geogrid manufacturers?

- Geogrid plays a very important role in road construction, which is mainly to reinforce roadbed and delay aging. The following is a detailed introduction: Geogrid on the road is mainly used for soft foundation treatment, roadbed reinforcement, slope protection, abutment reinforcement, wing wall, retaining wall, isolation and reinforcement of soil engineering.

- Q: What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the specific type of geogrid. In general, temperature can affect the mechanical properties of geogrids, such as tensile strength, stiffness, and creep behavior. Higher temperatures can soften the geogrid material, reducing its strength and stiffness. Conversely, lower temperatures can make the material more brittle. Therefore, it is important to consider the temperature conditions in which geogrids will be used to ensure their optimal performance and longevity.

Send your message to us

High Strength PP Biaxial Geogrid for Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords